30

EB 2520 EN

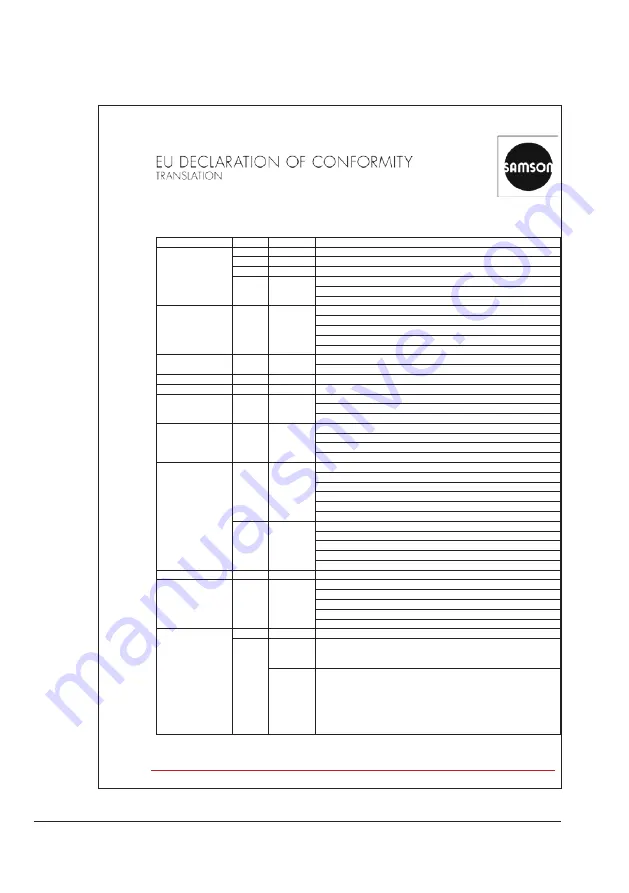

Certificates

Revision 00

Classification: Public · SAMSON AKTIENGESELLSCHAFT · Weismuellerstrasse 3 · 60314 Frankfurt am Main, Germany

Page 1 of 3

Module A

For the following products, SAMSON hereby declares under its sole responsibility:

Devices

Series

Type

Version

Self-operated Regulators

43

2432

DIN EN, body, CC499K and EN-GJS-400-18-LT, DN 50, PN 25, fluids G2, L2, L1

1)

43

2436

DIN EN, body, CC499K and EN-GJS-400-18-LT, DN 50, PN 25, fluids G2, L2, L1

1)

43

2437

DIN EN, body, CC499K and EN-GJS-400-18-LT, DN 50, PN 25, fluids G2, L2, L1

1)

---

2111

DIN EN, body, EN-GJS-400-18-LT, DN 50, PN 25, fluids G2, L2, L1

1)

DIN EN, body, 1.0619 and 1.4408, DN 40-50, PN 40, fluids G2, L2, L1

1)

ANSI, body, A216 WCC and A351 CF8M, NPS 1½-2, Class 300, fluids G2, L2, L1

1)

Three-way valve

---

2119

DIN EN, body, EN-GJL-250 and 1.0619, DN 65-125, PN 16, fluids G2, L2, L1

1)

DIN EN, body, 1.0619, DN 50-80, PN 25, fluids G2, L2, L1

1)

DIN EN, body, 1.0619 and 1.4408, DN 40-50, PN 40, fluids G2, L2, L1

1)

ANSI, body, A216 WCC and A351 CF8M, NPS 2½-4, Class 150, fluids G2, L2, L1

1)

ANSI, body, A216 WCC and A351 CF8M, NPS 1½, Class 300, fluids G2, L2, L1

1)

Control valve

---

3222

DIN EN, body, EN-GJS-400-18-LT, DN 50, PN 25, fluids G2, L2, L1

1)

DIN EN, body, CC499K, DN 32-40, PN 25, all fluids

Three-way valve

---

3226

DIN EN, body, CC499K, DN 50, PN 25, fluids G2, L2

2)

Three-way valve

---

3260

DIN EN, body, EN-GJL-250, DN 65-200, PN 16, fluids G2, L2

2)

Globe valve

Three-way valve

V2001

3531

3535

DIN EN, body, EN-GJS-400-18-LT, DN 50-80, PN 25, fluids G2, L2, L1

1)

DIN EN, body, 1.0619 and 1.4408, DN 32-40, PN 25, all fluids

ANSI, body, A216 WCC and A351 CF8M, NPS 1½-2, Class 150, all fluids

Control valve

---

3214

DIN EN, body, EN-GJL-250, DN 65-125, PN 16, fluids G2, L2, L1

1)

DIN EN, body, EN-GJS-400-18-LT, DN 50-80, PN 25, fluids G2, L2, L1

1)

ANSI, body, A126 B, NPS 3-4, Class 125, fluids G2, L2, L1

1)

ANSI, body, A216 WCC and A351 CF8M, NPS 1½-2, Class 150, all fluids

Self-operated Regulators

42

2423

DIN EN, body, EN-GJL-250 and EN-GJS-400-18-LT, DN 65-125, PN 16, fluids G2, L2, L1

1)

DIN EN, body, EN-GJS-418-LT, DN 50-80, PN 25, fluids G2, L2, L1

1)

DIN EN, body, 1.0619 and 1.4408, DN 32-50, PN 16, all fluids

DIN EN, body, 1.0619 and 1.4408, DN 32-40, PN 25, all fluids

ANSI, body, A126 B, NPS 3-4, Class 125, fluids G2, L2, L1

1)

ANSI, body, A216 WCC and A351 CF8M, NPS 1½-2, Class 150, all fluids

42

2422

DIN EN, body, EN-GJL-250 and EN-GJS-400-18-LT, DN 65-125, PN 16, fluids G2, L2, L1

1)

DIN EN, body, EN-GJS-400-18-LT, DN 50-80, PN 25, fluids G2, L2, L1

1)

DIN EN, body, 1.0619, 1.4408 and 1.6220+QT, DN 32-50, PN 16, all fluids

ANSI, body, A126 B, NPS 3-4, Class 125, fluids G2, L2, L1

1)

ANSI, body, A216 WCC, A351 CF8M and A352 LCC, NPS 1½-2, Class 150, all fluids

Strainers

1N/1NI

2601

DIN EN, body, CB752S, G 2 (DN50), PN25, fluids G2, L2

2)

Strainers

2N/2NI

2602

DIN EN, body, EN-GJL-250, DN 200-250, PN 10, fluids G2, L2, L1

1)

DIN EN, body, EN-GJL-250, DN 65-125, PN 16, fluids G2, L2, L1

1)

DIN EN, body, EN-GJS-400-18-LT, DN 100-125, PN 16, fluids G2, L2, L1

1)

DIN EN, body, EN-GJS-400-18-LT, DN 50-80, PN 25, fluids G2, L2, L1

1)

DIN EN, body, 1.4408, DN 32-50, PN 16, all fluids

Self-operated Regulators

---

2373/2375

ANSI, body, A995 4A and A995 5A, NPS 1½-2, Class 150, all fluids

44

2440 (44-0B)

2441 (44-1B)

2446 (44-6B)

DIN EN, body, EN-GJS-400-18-LT, DN 50, PN 25, fluids G2, L2, L1

1)

2442 (44-2)

2443 (44-3)

2444 (44-4)

2447 (44-7)

2448 (44-8)

2449 (44-9)

DIN EN, body, EN-GJS-400-18-LT and CC499K, DN 50, PN 25, fluids G2, L2, L1

1)

Summary of Contents for 2405 Series

Page 36: ...36 EB 2520 EN Certificates...