EB 8048 EN

25

Shipment and on-site transport

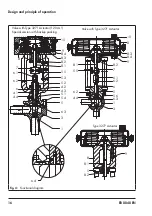

Fig. 7:

Ball body version of Type 3249 with

Type 3271 Actuator fitted with a lifting

eyelet

Lifting the control valve

1.

Carefully guide two slings through the

yoke and attach them to the rigging

equipment of the crane or forklift (see

Fig. 5 and Fig. 6). Make sure that the ac

-

tuator stem and valve accessories are not

damaged.

For actuator versions with lifting eyelet,

attach an additional sling to the lifting

eyelet of the actuator and to the rigging

equipment of the crane or forklift (see

2.

Carefully lift the control valve. Check

whether the lifting equipment and acces-

sories can bear the weight.

3.

Move the control valve at an even pace

to the site of installation.

4.

Install the valve into the pipeline (see sec-

5. After installation into the pipeline: de-

pending on the type of connection (e.g.

welding joint, flanged joint etc.) check

whether the valve in the pipeline holds.

6.

Remove slings.

4.4

Storing the valve

Risk of valve damage due to improper stor-

age.

Î

Observe the storage instructions.

Î

Avoid long storage times.

Î

Contact SAMSON in case of different

storage conditions or long storage peri-

ods.

We recommend regularly checking the con

-

trol valve and the prevailing storage condi-

tions during long storage periods.

Storage instructions

−

Protect the control valve against external

influences (e.g. impact).

−

Secure the valve in the stored position

against slipping or tipping over.

−

Do not damage the corrosion protection

(paint, surface coatings). Repair any

damage immediately.

−

Protect the control valve against moisture

and dirt. Store it at a relative humidity of

NOTICE

!

NOTICE

!

Note