2-2

EB 8055 EN

Markings on the device

The valve nameplate (80) is affixed to the

bonnet (see Fig. 2-2).

80

Fig. 2-2:

Nameplate on the bonnet

2.2 Actuator nameplate

See associated actuator documentation.

2.3 Material identification

number

The seat and plug of the valves have an item

number written on them. You can contact us

stating this item number to find out which

material is used. Additionally, a seat code is

used to identify the trim material. This seat

code is specified on the nameplate.

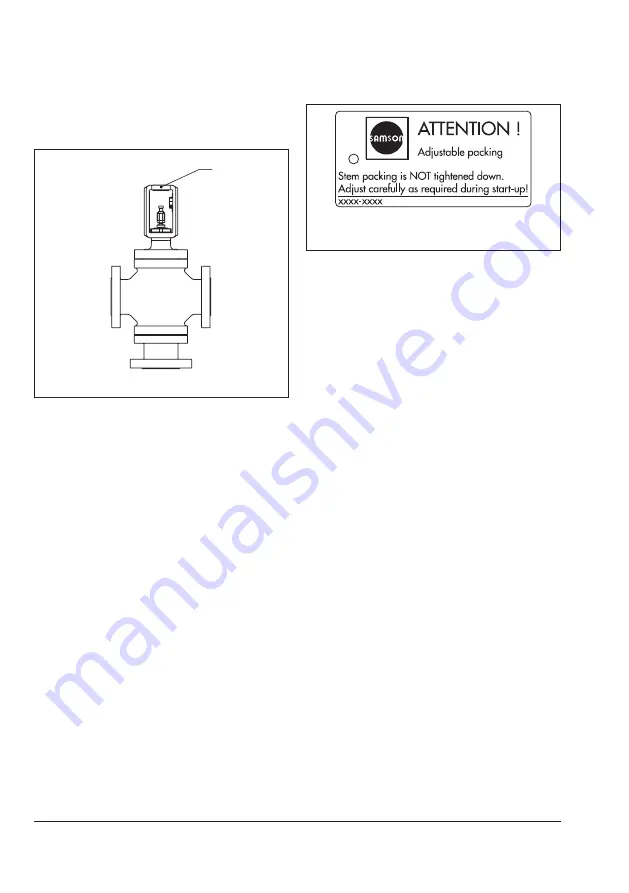

2.4 Label when an adjustable

packing is installed

An instructional label is affixed to the valve

when an adjustable packing is installed (see

Fig. 2-3).

Fig. 2-3:

Label when an adjustable packing is

installed

2.5 Optional RFID tag

The RFID tag is located directly next to the

nameplate on valves ordered with the RFID

tag option. It contains the same data as in

-

cluded in the Data Matrix code on the elec-

tronic nameplate. It can be read using a

smartphone, tablet or RFID reader.

Application range according to the technical

data (see the 'Design and principle of opera

-

tion' section).

Summary of Contents for 3253

Page 22: ...3 8 EB 8055 EN...

Page 27: ...EB 8055 EN 4 5 Shipment and on site transport...

Page 28: ...4 6 EB 8055 EN...

Page 74: ...12 2 EB 8055 EN...

Page 76: ...13 2 EB 8055 EN...

Page 79: ...EB 8055 EN 14 3...

Page 80: ...14 4 EB 8055 EN...

Page 81: ...EB 8055 EN 14 5...

Page 82: ...14 6 EB 8055 EN...

Page 88: ...15 6 EB 8055 EN...

Page 89: ......

Page 90: ......

Page 91: ......