EB 8055 EN

5-17

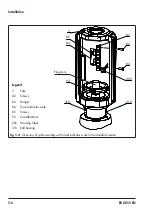

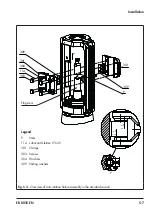

Installation

Crush hazard arising from actuator and

plug stem moving.

Î

Do not insert hands or finger into the

yoke while the air supply is connected to

the actuator.

Î

Before working on the control valve,

disconnect and lock the pneumatic air

supply as well as the control signal.

Î

Do not impede the movement of the actu-

ator and plug stem by inserting objects

into the yoke.

Î

Before unblocking the actuator and plug

stem after they have become blocked

(e.g. due to seizing up after remaining in

the same position for a long time),

release any stored energy in the actuator

(e.g. spring compression). See

associated actuator documentation.

Risk of personal injury due to exhaust air

being vented.

While the valve is operating, air is vented

from the actuator, for example, during

closed-loop operation or when the valve

opens or closes.

Î

Wear eye protection when working in

close proximity to the control valve.

Risk of personal injury due to preloaded

springs.

Actuators with preloaded springs are under

tension. They can be identified by the long

bolts protruding from the bottom of the actu-

ator.

Î

Before starting any work on the actuator,

relieve the compression from the pre-

loaded springs (see associated actuator

documentation).

To test the valve functioning before start-up

or putting back the valve into operation, per

-

form the following tests:

5.4.1

Leak test

The plant operator is responsible for per

-

forming the leak test and selecting the test

method. The leak test must comply with the

requirements of the national and internation

-

al standards that apply at the site of installa

-

tion.

Our after-sales service can support you to

plan and perform a leak test for your plant.

1. Slowly apply the test medium to the valve

until the test pressure is reached. Avoid

sudden surges in pressure since the re

-

sulting high velocities may damage the

valve.

2.

Check the valve for leakage to the atmo-

sphere.

3. Depressurize the pipeline section and

valve.

4. Rework any parts that leak (see informa-

tion below under ‘Adjusting the packing’)

and repeat the leak test.

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

Tip

Summary of Contents for 3253

Page 22: ...3 8 EB 8055 EN...

Page 27: ...EB 8055 EN 4 5 Shipment and on site transport...

Page 28: ...4 6 EB 8055 EN...

Page 74: ...12 2 EB 8055 EN...

Page 76: ...13 2 EB 8055 EN...

Page 79: ...EB 8055 EN 14 3...

Page 80: ...14 4 EB 8055 EN...

Page 81: ...EB 8055 EN 14 5...

Page 82: ...14 6 EB 8055 EN...

Page 88: ...15 6 EB 8055 EN...

Page 89: ......

Page 90: ......

Page 91: ......