26

EB 8310-5 EN

Operation

6 Operation

Crush hazard arising from moving parts.

The actuator contains moving parts (actuator

stem), which can injure hands or fingers if

inserted into the actuator.

−

Do not insert hands or fingers into the yoke

while the valve is in operation.

−

While working on the actuator, disconnect

and lock the pneumatic air supply as well

as the control signal.

Risk of personal injury when the actuator

vents.

Wear eye protection when working in close

proximity to the control valve.

Operating disturbed by a blocked actuator

stem.

Do not impede the movement of the actuator

stem by inserting objects into its path.

6.1 Throttling service

The Types 3271 and Type 3277 Pneumatic

Actuators with 175 and 750 cm² actuator

areas are designed for a maximum supply

pressure of 6 bar when used for throttling

service.

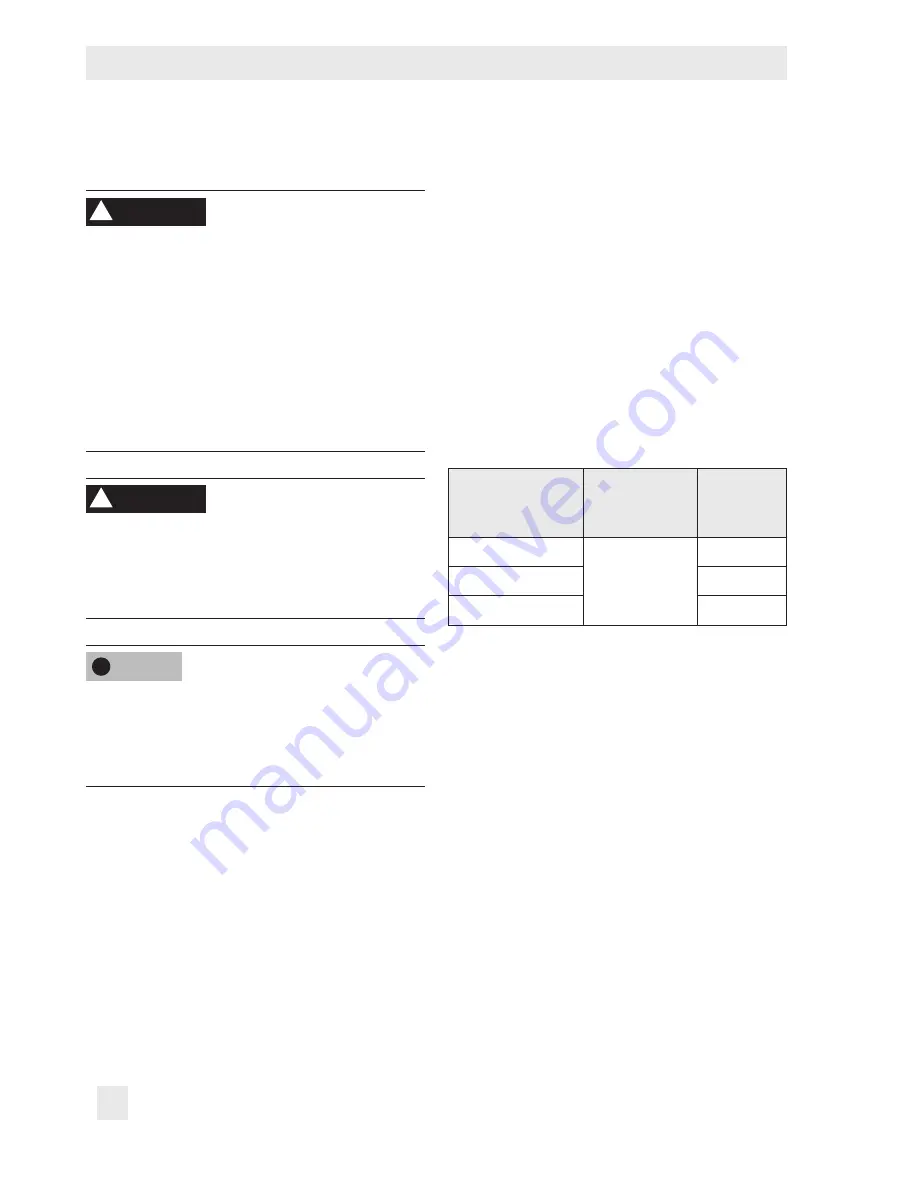

6.2 On/off service

In on/off service, the supply pressure must

be limited depending on the bench range or

operating range of the actuator. The applica-

ble bench range or operating range which

the actuator can move through is written on

the nameplate (see section 3.7).

Actuator stem retracts (FE)

For the direction of action "actuator stem re-

tracts (FE)", the permissible supply pressure

must not exceed the upper bench range val-

ue by more than 3 bar:

Bench range

Fail-safe

action

Max.

supply

pressure

0.2 to 1.0 bar

Actuator stem

retracts

4 bar

0.4 to 2.0 bar

5 bar

0.6 to 3.0 bar

6 bar

Actuator stem extends (FA)

With fail-safe action "actuator stem extends"

and travel stop, the supply pressure must not

exceed the upper spring range value by

more than 1.5 bar.

6.3 Manual mode

In Type 3271 and Type 3277 Pneumatic Ac-

tuators with 750 cm² actuator area and a

handwheel, the upper spring range value

must not exceed 3.1 bar.

WARNING

!

WARNING

!

NOTICE

!

Summary of Contents for 3277

Page 46: ...46 EB 8310 5 EN...

Page 47: ...EB 8310 5 EN 47...