2.1

Direct attachment

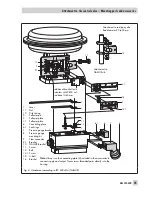

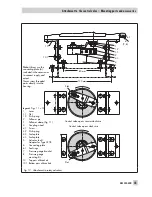

2.1.1 Type 3277-5 Actuator

Refer to Table 1 on page 16 for the required

mounting parts as well as the accessories

with their order numbers.

Note the travel table on page 15.

Actuator with 120 cm²

Depending on the type of positioner attach-

ment, the signal pressure is routed either left

or right of the yoke through a bore to the

actuator diaphragm. Depending on the

fail-safe action of the actuator "Actuator

stem extends" or "Actuator stem retracts"

(valve closes or opens if the supply air fails),

the switchover plate (9) must first be at-

tached to the actuator yoke. Align the

switchover plate with the corresponding

symbol for left or right attachment according

to the marking (view looking onto the

switchover plate).

1. Mount connecting plate (6) or pressure

gauge bracket (7) with pressure gauges

onto the positioner, making sure both

seal rings (6.1) are seated properly.

2. Remove screw plug (4) on the back of

the positioner and close the signal pres-

sure output "Output 38" on the connect-

ing plate (6) or on the pressure gauge

bracket (7) with the stopper (5) included

in the accessories.

3. Place follower clamp (3) on the actuator

stem, align and screw tight so that the

mounting screw is located in the groove

of the actuator stem.

4. Mount cover plate (10) with narrow side

of the cut-out opening (Fig. 4, left) point-

ing towards the signal pressure connec-

tion. Make sure that the bonded gasket

(14) points towards the actuator yoke.

5.

15 mm travel:

Keep the follower pin (2)

at lever

M

(1) on the back of the

positioner in the pin position

35

(deliv-

ered state).

7.5 mm travel:

Remove the follower pin

(2) from the pin position

35

, reposition it

in the bore for pin position

25

and

screw tight.

6. Insert formed seal (15) into the groove of

the positioner housing and the seal ring

(10.1) on the back of the housing.

7. Place positioner on the cover plate (10)

in such a manner that the follower pin

(2) rests on the top of the follower clamp

(3). Adjust the lever (1) correspondingly

and open the positioner cover to hold

the positioner shaft in position at the cap

or the switch (Fig. 23).

The lever (1) must rest on the follower

clamp with spring force.

Mount the positioner on the cover plate

(10) using the two fixing screws.

Note for all types of attachment except for

direct attachment to Type 3277-5:

The sig-

nal pressure output at the back must be

sealed using the screw plug (4, order no.

0180-1254) and the associated O-ring (or-

der no. 0520-0412).

8. Mount cover (11) on the other side. Make

sure that the vent plug points downwards

when the control valve is installed to al-

low any condensed water that collects to

drain off.

20

EB 8384-4 EN

Attachment to the control valve – Mounting parts and accessories

Summary of Contents for 3730-4

Page 2: ...2 EB 8384 4 EN...

Page 127: ......

Page 188: ...188 EB 8384 4 EN...

Page 189: ...EB 8384 4 EN 189...

Page 190: ...190 EB 8384 4 EN...

Page 191: ...EB 8384 4 EN 191...

Page 192: ...192 EB 8384 4 EN...

Page 193: ...EB 8384 4 EN 193...

Page 194: ...194 EB 8384 4 EN...

Page 195: ...EB 8384 4 EN 195...

Page 196: ...196 EB 8384 4 EN...

Page 197: ...EB 8384 4 EN 197...

Page 198: ...198 EB 8384 4 EN...

Page 199: ...EB 8384 4 EN 199...

Page 206: ...206 EB 8384 4 EN...

Page 207: ...EB 8384 4 EN 207...

Page 208: ...208 EB 8384 4 EN...

Page 209: ...EB 8384 4 EN 209...

Page 210: ...210 EB 8384 4 EN...

Page 211: ...EB 8384 4 EN 211...