ator and take several minutes.

Positioners with EXPERT

+

diagnostic func-

tions start plotting the reference graphs after

the initialization process has been com-

pleted. See note at the end of this section.

WARNING!

During the initialization, the control

valve moves through its entire tra-

vel/angle of rotation range. Therefo-

re, do not start initialization while a

process is running, but only during

start-up, when all shut-off valves are

closed.

Note:

The initialization procedure

can be interrupted while running by

pressing

.

StOP

appears three se-

conds long and the positioner then

moves to the fail-safe position.

The fail-safe position can be cance-

led again over Code

0

.

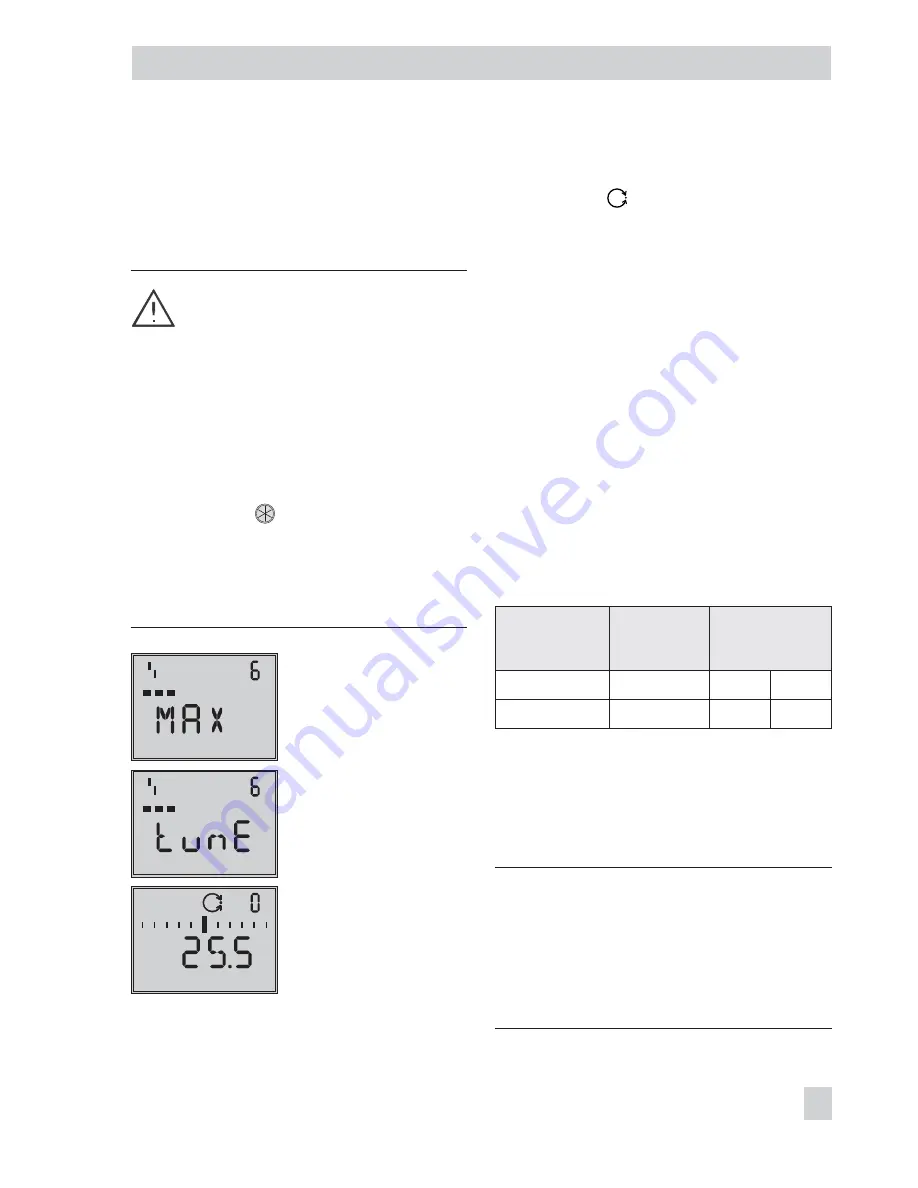

Alternating displays

Initialization running

Symbol depending on in-

itialization mode selected

Bar graph display

indicating the progress of

the initialization

Initialization successful,

positioner in automatic

operating mode

After a successful initialization, the

positioner runs in closed-loop operation in-

dicated by the

closed-loop operation

icon.

The control position in % predetermined by

the reference variable appears on the dis-

play.

A malfunctioning leads to the process being

interrupted. The initialization error appears

on the display according to how it has been

classified by the condensed status. See sec-

tion 5.7 on page 70.

If the slide switch is set to AIR TO CLOSE,

the positioner automatically switches to the

direction of action increasing/decreasing

(

äæ

) on successful completion of initializa-

tion. This results in the following assignment

between reference variable and valve posi-

tion:

Valve closed

position

Direction of

action

Reference variable

Valve

Closed at Open at

AIR TO OPEN

ää

0 %

100 %

AIR TO CLOSE

äæ

100 %

0 %

The tight-closing function is activated.

Set Code

15

(final position w>) to 99 % for

three-way valves.

Further settings relevant for the valve can be

entered subsequently.

Note on EXPERT

+

:

Positioner with integrated

EXPERT

+

diagnostics automatically start to

plot the reference graphs (drive signal y d1

and hysteresis d2) after initialization has

been completed. TEST d1 and d2 appear on

the display in an alternating sequence.

EB 8384-4 EN

63

Start-up and settings

%

Summary of Contents for 3730-4

Page 2: ...2 EB 8384 4 EN...

Page 127: ......

Page 188: ...188 EB 8384 4 EN...

Page 189: ...EB 8384 4 EN 189...

Page 190: ...190 EB 8384 4 EN...

Page 191: ...EB 8384 4 EN 191...

Page 192: ...192 EB 8384 4 EN...

Page 193: ...EB 8384 4 EN 193...

Page 194: ...194 EB 8384 4 EN...

Page 195: ...EB 8384 4 EN 195...

Page 196: ...196 EB 8384 4 EN...

Page 197: ...EB 8384 4 EN 197...

Page 198: ...198 EB 8384 4 EN...

Page 199: ...EB 8384 4 EN 199...

Page 206: ...206 EB 8384 4 EN...

Page 207: ...EB 8384 4 EN 207...

Page 208: ...208 EB 8384 4 EN...

Page 209: ...EB 8384 4 EN 209...

Page 210: ...210 EB 8384 4 EN...

Page 211: ...EB 8384 4 EN 211...