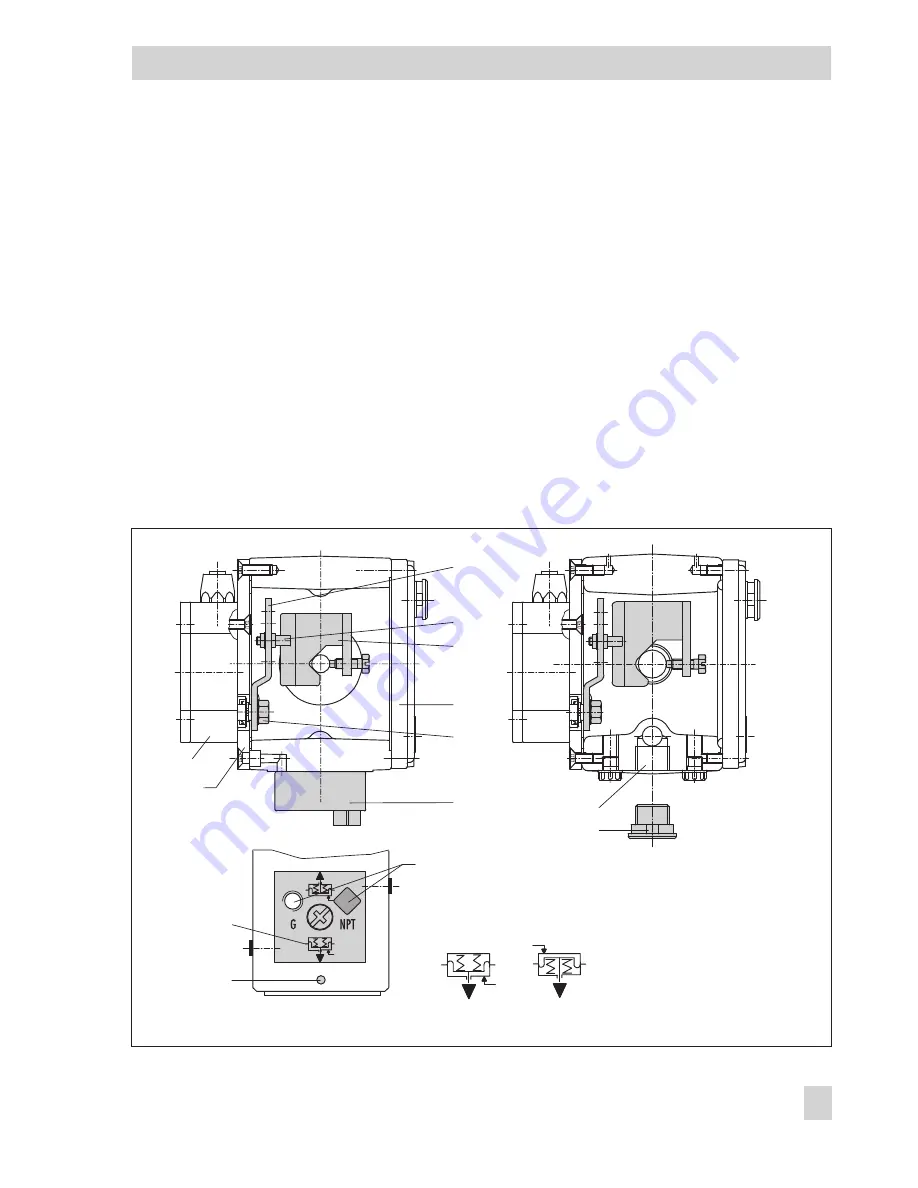

Type 3277 Actuator with 240 to 700 cm²

The signal pressure is routed to the connec-

tion at the side of the actuator yoke for the

version "Actuator stem extends".

For the fail-safe position "Actuator stem re-

tracts" the connection on the top diaphragm

case is used. The connection at the side of

the yoke must be fitted with a venting plug

(accessories).

Mounting the position sensor

1. Place the lever (1) on the sensor in

mid-position and hold it in place.

Unthread the nut (1.1) and remove the

lever together with the disk spring (1.2)

from the sensor shaft.

2. Screw the position sensor (20) onto the

mounting plate (21).

3. Depending on the actuator size and

rated valve travel, determine the re-

quired lever and position of the fol-

lower pin (2) from the travel table on

page 21.

The positioner is delivered with lever

M

in pin position

35

on the sensor. If nec-

essary, remove the follower pin (2)

from its pin position and move it to the

borehole for the recommended pin po-

sition and screw tight.

4. Place the lever (1) and disk spring (1.2)

on the sensor shaft.

EB 8384-6 EN

35

Attachment to the control valve – Mounting parts and accessories

20

21

9

11

1.1

1.2

3

2

1

Fig. 13 · Mounting for Type 3277-5 Actuator (left) and Type 3277 Actuator (right)

Signal pressure

Vent plug

Actuator stem

extends

retracts

Symbol

Marking

Signal pressure

1

Lever

1.1 Nut

1.2 Disk spring

2

Follower pin

3

Follower clamp

9

Connecting plate

11 Cover

20 Position sensor

21 Mounting plate

Summary of Contents for 3730-6

Page 19: ...EB 8384 6 EN 19...

Page 51: ...EB 8384 6 EN 51...

Page 113: ...EB 8384 6 EN 113...

Page 114: ...114 EB 8384 6 EN...

Page 115: ...EB 8384 6 EN 115...

Page 116: ...116 EB 8384 6 EN...

Page 117: ...EB 8384 6 EN 117...

Page 118: ...118 EB 8384 6 EN...

Page 119: ...EB 8384 6 EN 119...

Page 120: ...120 EB 8384 6 EN...

Page 123: ...EB 8384 6 EN 123 diagnostic functions 11 Z Zero calibration 68 Index...