EB 8355-2 EN

5-21

Installation

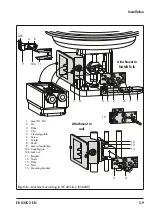

Check the positioning speed by pushing

the diaphragm lever (3 in

it will go.

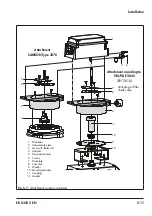

2. Adjust the set point at the input to ap-

prox. 50 % of its range. Then turn the ze

-

ro adjuster (6.2 in

) until the

valve is at approximately 50 % valve

travel.

3. Use the adjuster (8 in

proportional band X

p

to a value half way

(half turn).

4. Check the valve's tendency to hunt and

the positioning speed by briefly tapping

the diaphragm lever (3 in

). The

Xp value is to be adjusted to be as small

as possible, without considerable over-

shooting occurring.

Additional points that apply concerning ad

-

justment:

Î

Always adjust the Xp restriction before

setting the starting point.

Î

In case of a zero shift (e.g. due to a sub

-

sequent change in the restriction setting

or supply pressure), check the zero set

-

ting and readjust it.

−

When the positioner is controlled by a

computer whose signal is limited, e.g.

between 4 to 20 mA, set the positioner

to the range from 4.5 to 20 mA. This is

the only way to ensure that the actuator

is completely vented and the valve com-

pletely closed when the controller issues

a 4 mA signal. For operating direction

<>, set the range to 4 to 19.5 mA.

5.5.2

Zero and span

When setting the zero adjuster (6.2 in

), check whether the actuator is re

-

lieved of pressure. When the input signal is

4 mA and the operating direction >> or the

input signal is 20 mA and the operating di

-

rection <>, the pressure gauge must indicate

0 bar.

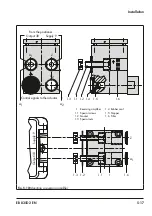

a) Actuator with "stem extends"

fail-safe action

To ensure that the total closing force of the

actuator acts on the valve, proceed as fol-

lows while adjusting the set point:

Î

With operating direction increasing/in

-

creasing <<: adjust starting point to

4.5 mA (slightly raised).

Î

With operating direction increasing/de

-

creasing <>: adjust starting point to

19.5 mA (slightly lowered).

Starting point (zero) e.g. 4 mA

1.

Turn the zero adjuster (6.2 in Fig. 5-3

)

until the valve just starts to move from its

initial position.

2.

Reduce the input signal to 0 mA and

slowly increase it again. Check whether

the valve starts to move at exactly

4.5 mA.

Correct any deviation at the zero adjust

-

).

Note

Summary of Contents for 3767

Page 10: ...1 6 EB 8355 2 EN...

Page 14: ...2 4 EB 8355 2 EN...

Page 58: ...6 2 EB 8355 2 EN...

Page 60: ...7 2 EB 8355 2 EN...

Page 70: ...10 2 EB 8355 2 EN...

Page 72: ...11 2 EB 8355 2 EN...

Page 74: ...12 2 EB 8355 2 EN...

Page 76: ...13 2 EB 8355 2 EN...

Page 78: ...14 2 EB 8355 2 EN...

Page 79: ...EB 8355 2 EN 14 3...

Page 80: ...14 4 EB 8355 2 EN...

Page 81: ...EB 8355 2 EN 14 5...

Page 88: ...14 12 EB 8355 2 EN...

Page 89: ...EB 8355 2 EN 14 13...

Page 90: ...14 14 EB 8355 2 EN...

Page 91: ...EB 8355 2 EN 14 15...

Page 92: ...14 16 EB 8355 2 EN...

Page 93: ...EB 8355 2 EN 14 17...

Page 94: ...14 18 EB 8355 2 EN...

Page 95: ...EB 8355 2 EN 14 19...

Page 96: ...14 20 EB 8355 2 EN...

Page 97: ...EB 8355 2 EN 14 21...

Page 98: ...14 22 EB 8355 2 EN...

Page 99: ...EB 8355 2 EN 14 23...

Page 100: ...14 24 EB 8355 2 EN...

Page 101: ...EB 8355 2 EN 14 25...

Page 102: ...14 26 EB 8355 2 EN...

Page 103: ...EB 8355 2 EN 14 27...

Page 104: ...14 28 EB 8355 2 EN...

Page 109: ......

Page 110: ...2 EB 8355 2 EN...

Page 111: ...EB 8355 2 EN 3...