3. Connections

3.1 Pneumatic connections

The air connections are either NPT 1/4 or

G 1/4 tapped holes. The customary fittings

for metal and copper tubes or plastic hoses

can be used.

NOTE

The supply air must be dry and free from oil

and dust. The maintenance instructions for

upstream pressure reducing stations must

be adhered to. Carefully purge all air tubes

and hoses before connecting them.

If the positioner is attached directly to the

Type 3277 Actuator, the connection of the

positioner output pressure to the actuator is

fixed. For NAMUR attachment, the signal

pressure can be applied to either the upper

or lower diaphragm chamber of the actua-

tor, depending on the actuator’s fail-safe ac-

tion (either "Actuator stem retracts" or "stem

extends").

Exhaust air:

The exhaust air connection of

the positioner is located at the mounting kit.

For direct attachment of the positioner, a

vent plug is located at the plastic cover of

the actuator. For NAMUR attachment, the

vent plug can be found at the adapter hous-

ing and for attachment to rotary actuators,

it is either located at the intermediate piece

or the reversing amplifier.

To guarantee the IP 65 degree of protec-

tion, the vent plug must be replaced with

the filter check valve included with the de-

vice. See also chapter 2 on page 10.

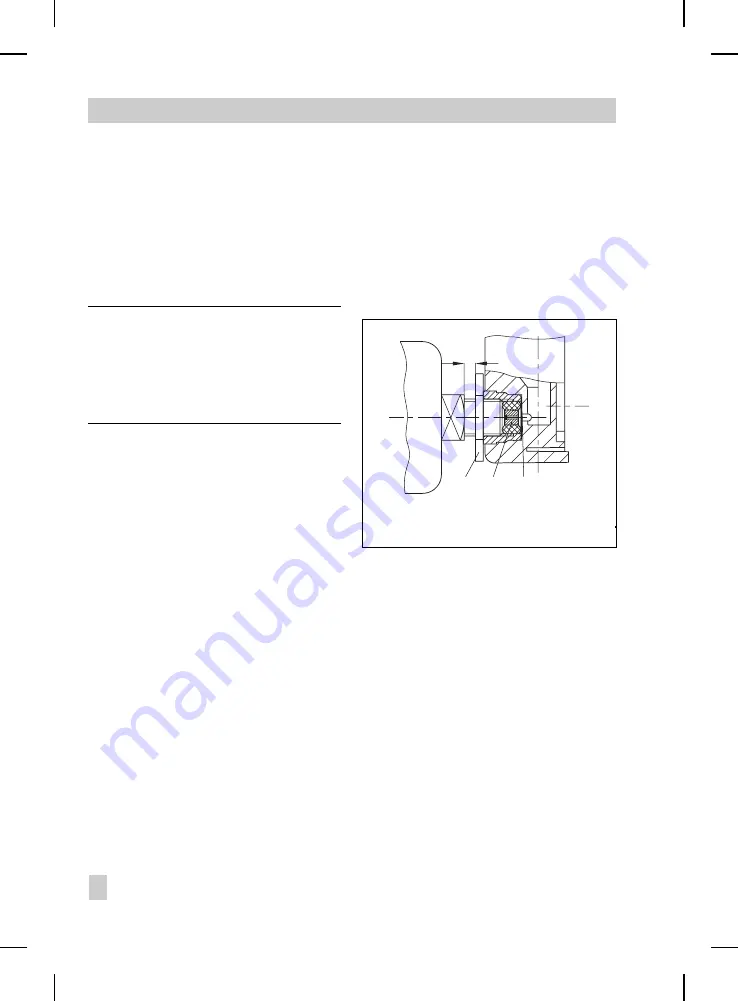

3.1.1 Pressure gauge

To monitor the positioner operation, it is

recommended that pressure gauges for sup-

ply air and signal pressure indication to the

positioner be connected. These parts are

listed as accessories in Table 3, 4 or 6.

Fig. 8

⋅

Mounting the pressure gauge

2...3mm

Nut Throttle Filter

24

EB 8382-1 EN

Connections

Summary of Contents for 3785 series

Page 69: ...EB 8382 1 EN 69...

Page 70: ...70 EB 8382 1 EN...

Page 71: ...EB 8382 1 EN 71...

Page 72: ...72 EB 8382 1 EN...

Page 73: ...EB 8382 1 EN 73...

Page 74: ...74 EB 8382 1 EN...

Page 75: ...EB 8382 1 EN 75...

Page 76: ...76 EB 8382 1 EN...

Page 77: ...EB 8382 1 EN 77...

Page 78: ...78 EB 8382 1 EN...

Page 79: ...EB 8382 1 EN 79...