EB 3131 EN

25

Mounting and start-up

5.2 Additional fittings

Strainer

A strainer installed upstream in the flow pipe

holds back any dirt or other foreign particles

carried along by the medium. For example,

the SAMSON Type 1 NI Strainer is suitable

(

u

−

Do not use the strainer to permanently

filter the process medium.

−

Install the strainer upstream of the regu-

lator.

−

The direction of flow must correspond to

the arrow on the valve body.

−

The filter element must be installed to

hang downward.

−

Allow sufficient space to remove the filter.

Shut-off valve

Install a hand-operated shut-off valve both

upstream of the strainer and at the outlet of

the return flow pipe (see Fig. 4). This allows

the plant to be shut down for cleaning and

maintenance, and when the plant is not used

for longer periods of time.

Pressure gauge

Install a pressure gauge at a suitable point to

monitor the pressures prevailing in the plant

(see Fig. 4).

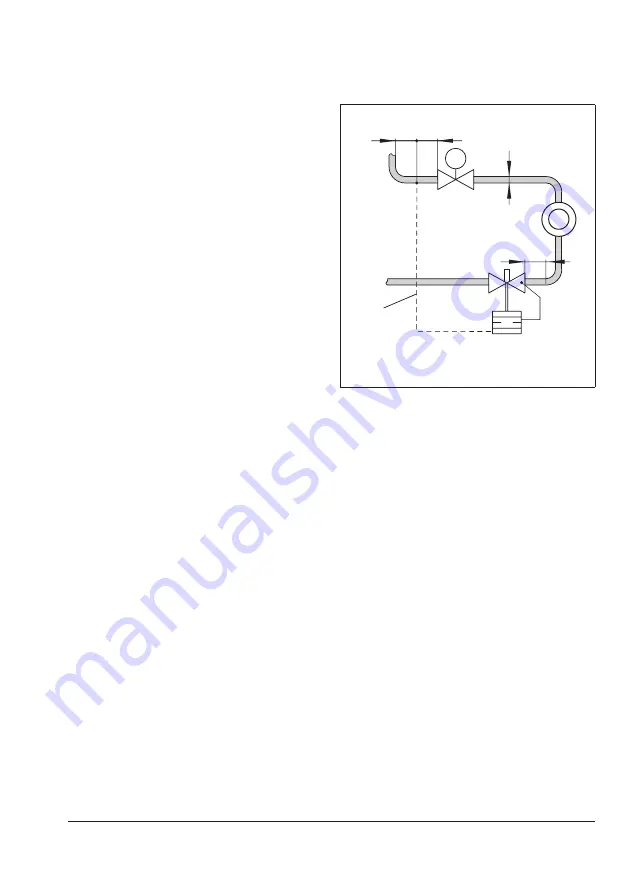

Control line

Depending on the regulator version, a con-

trol line (standard: 6x1 mm pipe diameter)

must be adapted and mounted on site. Make

sure that the control line is free of dirt.

We recommend installing the control line for

tapping pressure from the pipeline at a dis-

tance of at least three times the nominal size

(DN) away from any pipe fittings (e.g. mani

-

folds, bends, branches or other valves), that

may cause turbulence in the flow.

How the lines are routed generally depends

on the installation site. Preferably connect the

control line to the side of the main pipe.

Î

Do not change the pipe diameter of the

main pipeline with an eccentric reducer.

Î

Refer to installation schematics (Fig. 4)

for line routing.

M

DN

min.

3 x DN

min.

3 x DN

min.

3 x DN

Control

line

Fig. 5:

Control line connection, depending on

how the pipeline is routed