22

EB 8384-1 EN

Attachment to the control valve – Mounting parts and accessories

4.3

Attachment according to

VDI/VDE 3847

The following positioners with air purging of

the actuator's spring chamber can be at-

tached according to VDI/VDE 3847:

−

Type 3730-1xx0000000x00

6

000

−

Type 3730-1xx0000000x00

7

000

Type 3730-1xx0000000x00

0

000 Positioner

without air purging of the actuator's spring

chamber can be attached according to VDI/

VDE 3847.

This type of attachment allows the positioner

to be replaced quickly while the process is

running by blocking the air in the actuator.

The signal pressure can be blocked in the

actuator by unscrewing the red retaining

screw (20) and turning the air blocker (19)

on the bottom of the adapter block.

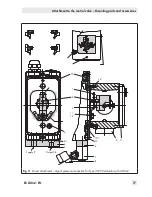

Attachment to Type 3277 Actuator (see

Fig. 6)

−

Required mounting parts and accesso-

ries: Table 4 on page 39

Mount the positioner on the yoke as shown

in Fig. 6. The signal pressure is routed to the

actuator over the connecting plate (12), for

actuators with fail-safe action "actuator stem

extends" internally through a bore in the

valve yoke and for "actuator stem retracts"

through external piping.

Only the Y1 port is required for positioner

attachment. The Y2 port can be used for air

purging of the spring chamber.

1.

Place follower clamp (3) on the actuator

stem, align it and screw tight so that the

mounting screw is located in the groove

of the actuator stem.

2.

Place the adapter bracket (6) on the po-

sitioner and mount using the screws (6.1).

Make sure that the seals are correctly

seated. For positioners

with air purging

,

remove the stopper (5) before mounting

the positioner. For positioners

without air

purging

, replace the screw plug (4) with

a vent plug.

3.

For actuators with 355, 700 or 750 cm²,

remove the follower pin (2) on the M le-

ver (1) on the back of the positioner from

pin position 35, reposition it in the hole

for pin position 50 and screw tight.

For actuators 175, 240 and 350 cm²

with 15 mm travel, keep the follower pin

(2) in pin position 35.

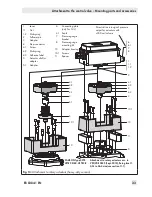

4.

Insert the formed seal (6.2) in the groove

of the adapter bracket (6).

5. Insert the formed seal (17.1) into the turn-

board (17) and mount the turnboard to

the adapter block (13) using the screws

(17.2).

6.

Mount the blank plate (18) to the turn-

board (17) using the screws (18.1). Make

sure that the seals are correctly seated.

Note:

A solenoid valve can also be mount-

ed in place of the blank plate (18).

The orientation of the turnboard (17)

determines the mounting position of

the solenoid valve. Alternatively, a re-

strictor plate can be mounted

(

u

AB 11).

Fig. 6:

Attachment according to VDI/VDE 3847 to Type 3277 Actuator

1

Lever

1.1

Nut

1.2

Disk spring

2

Follower pin

3

Follower clamp

4

Screw plug

5

Stopper

6

Adapter bracket

6.1

Screws

6.2

Formed seal

6.3

Screws

11

Cover

11.1

Vent plug

12

Connecting plate

12.1

Seal

13

Adapter block

13.1

Screws

17

Turnboard

17.1

Formed seal

17.2

Screws

18

Blank plate

18.1

Screws

19

Air blocker

20

Retaining screw

18.1

1

17.2 18

17

17.1

13.1

13

12

12.1

3

11.1

11

19

20

Exh.

1.1

1.2

1.1

1.2

1

2

6.2 6.1

6

4

6.3

5

Summary of Contents for TROVIS 3730-1

Page 64: ...64 EB 8384 1 EN...

Page 65: ...EB 8384 1 EN 65...

Page 66: ...66 EB 8384 1 EN...

Page 67: ...EB 8384 1 EN 67...

Page 68: ...68 EB 8384 1 EN...

Page 69: ...EB 8384 1 EN 69...

Page 70: ...70 EB 8384 1 EN...

Page 71: ...EB 8384 1 EN 71...

Page 72: ...72 EB 8384 1 EN...

Page 73: ...EB 8384 1 EN 73...

Page 74: ...74 EB 8384 1 EN...

Page 75: ...EB 8384 1 EN 75...