32

EB 8384-1 EN

Attachment to the control valve – Mounting parts and accessories

4.5.3

Heavy-duty version

−

Required mounting parts and accesso-

ries: Table 5

Both mounting kits contain all the necessary

mounting parts. The parts for the actuator

size used must be selected from the mount-

ing kit.

Prepare actuator, and mount required

adapter supplied by the actuator manufac-

turer, if necessary.

1.

Mount the housing (10) onto the rotary

actuator. In case of VDI/VDE attachment,

place spacers (11) underneath, if neces-

sary.

2. For

SAMSON Type 3278 and VETEC

S160 Rotary Actuators

, screw the adapt-

er (5) onto the free end of the shaft or

place adapter (5.1) onto the shaft of the

VETEC R Actuator

. Place adapter (3) on-

to

Type 3278, VETEC S160 and VETEC R

Actuators

. For VDI/VDE version, this step

depends on the actuator size.

3.

Stick adhesive label (4.3) onto the cou-

pling in such a manner that the yellow

part of the sticker is visible in the window

of the housing when the valve is OPEN.

Adhesive labels with explanatory sym-

bols are enclosed and can be stuck on

the housing, if required.

4.

Fasten coupling (4) on the slotted actua-

tor shaft or adapter (3) using screw (4.1)

and disk spring (4.2).

5. Unscrew the standard follower pin (2)

from the positioner's M lever (1).

Attach the follower pin (Ø 5 mm) includ-

ed in the mounting kit to pin position

90°.

6.

Mount connecting plate (6) for required

G ¼ connecting thread or pressure

gauge bracket (7) with pressure gauges

on the positioner, making sure the two

seals (6.1) are seated properly. Double-

acting springless rotary actuators require

the use of a reversing amplifier on the

connection side of the positioner housing

(refer to section 4.6).

7. For actuators with a volume of less than

300 cm³, fit the restriction (order no.

1400-6964) into the signal pressure out-

put of the positioner (or the output of the

pressure gauge bracket or connecting

plate).

8.

Place positioner on housing (10) and

screw it tight. Taking the actuator's direc-

tion of rotation into account, adjust lever

(1) so that it engages in the correct slot

with its follower pin (Fig. 12).

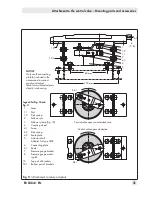

Actuator turning counterclockwise

Actuator turning clockwise

1

10

4

Fig. 12:

Direction of rotation

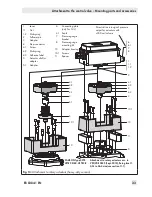

6

6.1

7

8

1

1.1

1.2

2

4.1

3

10.1

10

11

5

4.3

4

4.2

4.1

3

5.1

5

10.1

10

4.3

4

4.2

1

Lever

1.1

Nut

1.2

Disk spring

2

Follower pin

3

Adapter

4

Stem connector

4.1

Screw

4.2

Disk spring

4.3

Adhesive label

5

Actuator shaft or

adapter

5.1

Adapter

6

Connecting plate

(only for G ¼)

6.1

Seals

7

Pressure gauge

bracket

8

Pressure gauge

mounting kit

10

Adapter housing

10.1

Screws

11

Spacer

SAMSON Type 3278

VETEC S160, VETEC R

Attachment to rotary actuators acc. to

VDI/VDE 3845 (Sept. 2010), fixing level 1,

AA1 to AA4 size (see section 11.1)

Fit restriction into signal pressure

output for actuators with

<300 cm³ volume

Fig. 13:

Attachment to rotary actuators (heavy-duty version)

Summary of Contents for TROVIS 3730-1

Page 64: ...64 EB 8384 1 EN...

Page 65: ...EB 8384 1 EN 65...

Page 66: ...66 EB 8384 1 EN...

Page 67: ...EB 8384 1 EN 67...

Page 68: ...68 EB 8384 1 EN...

Page 69: ...EB 8384 1 EN 69...

Page 70: ...70 EB 8384 1 EN...

Page 71: ...EB 8384 1 EN 71...

Page 72: ...72 EB 8384 1 EN...

Page 73: ...EB 8384 1 EN 73...

Page 74: ...74 EB 8384 1 EN...

Page 75: ...EB 8384 1 EN 75...