46

EB 8384-6S EN

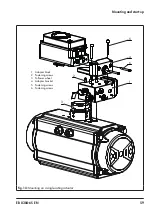

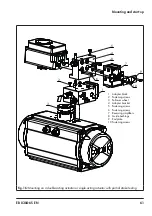

Mounting and start-up

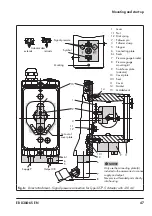

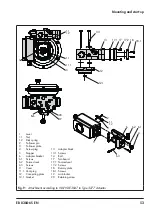

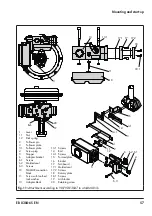

5.3 Direct attachment

5.3.1

Type 3277-5 Actuator

Î

Required mounting parts and accesso

-

ries: Table 3

Î

Observe the travel table on page 28.

Actuator with 120 cm²

The signal pressure from the positioner is

routed over the signal pressure connection of

the connecting plate (9, Fig. 25 left) to the

actuator diaphragm chamber. To proceed,

first screw the connecting plate (9) included

in the accessories onto the actuator yoke.

−

Turn the connecting plate (9) so that the

correct symbol for the fail-safe action

"actuator stem extends" or "actuator stem

retracts" is aligned with the marking (Fig.

25, below).

−

Make absolutely sure that the gasket for

the connecting plate (9) is correctly insert-

ed.

−

The connecting plate has threaded holes

with NPT and G threads. Seal the thread-

ed connection that is not used with the

rubber seal and square plug.

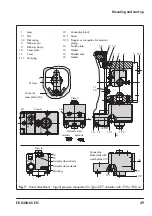

3. Mount connecting plate (6) or pressure

gauge bracket (7) with pressure gauges

on the positioner, making sure the two

seals (6.1) are seated properly.

4. Place follower clamp (3) on the actuator

stem, align it and screw tight so that the

mounting screw is located in the groove

of the actuator stem.

5. Mount cover plate (10) with narrow side

of the cut-out (Fig. 6, on the left) pointing

towards the signal pressure connection.

Make sure that the gasket (14) points to-

wards the actuator yoke.

6.

15 mm travel:

Keep the follower pin (2)

on the M lever (1) on the back of the po-

sitioner in the pin position 35 (delivered

state).

7.5 mm travel:

Remove the follower pin

(2) from the pin position 35, reposition it

in the hole for pin position 25 and screw

tight.

7. Insert molded seal (15) into the groove of

the positioner housing and insert the seal

(10.1) on the back of the housing.

8. Place positioner on the cover plate (10)

in such a manner that the follower pin

(2) rests on the top of the follower clamp

(3). Adjust the lever (1) correspondingly

and open the positioner cover to hold the

positioner shaft in position at the cap or

rotary pushbutton. The lever (1) must rest

on the follower clamp with spring force.

Fasten the positioner on the cover plate

(10) using the two fastening screws.

The following applies to all types of attach

-

ment except for direct attachment to

Type 3277-5:

The signal pressure output at the back must

be sealed by the screw plug (4, order no.

0180-1436) and the associated O-ring (or-

der no. 0520-0412).

9. Mount cover (11) on the other side.

Make sure that the vent plug is located at

the bottom when the control valve is in-

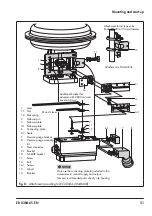

NOTICE

!

Only use the connecting plate (6)

included in the accessories to connect

supply and output.

Never screw threaded parts directly

into housing.

9 11

Supply 9

Output 38

5

6

7

6

10

10.1

3

2

1

15

6.1

1.1

1.2

14

8

Actuator stem

extends

retracts

Symbol

Marking

Cut-out of

cover plate

1

Lever

1.1 Nut

1.2 Disk spring

2

Follower pin

3

Follower clamp

5

Stopper

6

Connecting plate

6.1 Seals

7

Pressure gauge bracket

8

Pressure gauge

mounting kit

9

Switchover plate

(actuator)

10

Cover plate

10.1 Seal

11

Cover

14

Gasket

15

Molded seal

Signal pressure

Fig. 6:

Direct attachment – Signal pressure connection for Type 3277-5 Actuator with 120 cm²

Note

Summary of Contents for TROVIS SAFE 3730-6

Page 12: ...12 EB 8384 6S EN...

Page 16: ...16 EB 8384 6S EN...

Page 22: ...22 EB 8384 6S EN...

Page 40: ...40 EB 8384 6S EN...

Page 42: ...42 EB 8384 6S EN...

Page 82: ...82 EB 8384 6S EN...

Page 90: ...90 EB 8384 6S EN...

Page 96: ...96 EB 8384 6S EN...

Page 132: ...132 EB 8384 6S EN...

Page 152: ...152 EB 8384 6S EN...

Page 155: ...EB 8384 6S EN 155...

Page 156: ...156 EB 8384 6S EN...

Page 157: ...EB 8384 6S EN 157...

Page 158: ...158 EB 8384 6S EN...

Page 159: ...EB 8384 6S EN 159...

Page 160: ...160 EB 8384 6S EN...

Page 161: ...EB 8384 6S EN 161...

Page 162: ...162 EB 8384 6S EN...

Page 163: ...EB 8384 6S EN 163...

Page 164: ...164 EB 8384 6S EN...

Page 165: ...EB 8384 6S EN 165...

Page 166: ...166 EB 8384 6S EN...

Page 167: ...EB 8384 6S EN 167...

Page 182: ...182 EB 8384 6S EN...

Page 183: ...EB 8384 6S EN 183...