EB 8384-6S EN

73

Mounting and start-up

− In addition, the instructions in sections 5.15

and 5.16 apply for the pneumatic and

electrical connection.

Operation and setting are described in

section

.

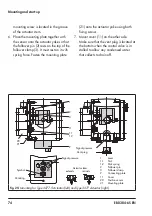

− Since 2009, the back of the position sen-

sor (20) is fitted with two pins acting as

mechanical stops for the lever (1). If this

position sensor is mounted using old

mounting parts, two corresponding

Ø 8 mm holes must be drilled into the

mounting plate/bracket (21). A template is

available for this purpose. See Table 8.

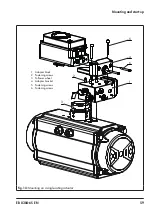

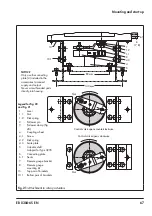

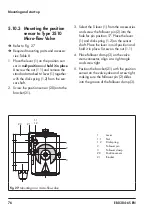

5.10.1 Mounting the position

sensor with direct at-

tachment

Type 3277-5 Actuator with 120 cm² (Fig. 25)

The signal pressure from the positioner is

routed over the signal pressure connection of

the connecting plate (9, Fig. 25 left) to the

actuator diaphragm chamber. To proceed,

first screw the connecting plate (9) included

in the accessories onto the actuator yoke.

−

Turn the connecting plate (9) so that the

correct symbol for the fail-safe action

"actuator stem extends" or "actuator stem

retracts" is aligned with the marking (Fig.

25, below).

−

Make absolutely sure that the gasket for

the connecting plate (9) is correctly insert-

ed.

−

The connecting plate has threaded holes

with NPT and G threads. Seal the thread-

ed connection that is not used with the

rubber seal and square plug.

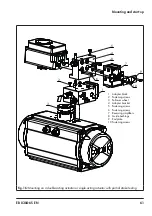

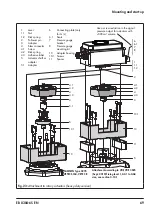

Type 3277 Actuator with 175 to 750 cm²:

The signal pressure is routed to the connec-

tion at the side of the actuator yoke for the

version with fail-safe action "actuator stem

extends". For the fail-safe action "actuator

stem retracts" the connection on the top dia-

phragm case is used. The connection at the

side of the yoke must be fitted with a venting

plug (accessories).

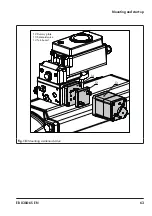

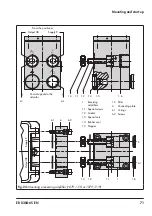

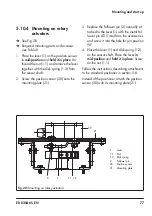

Mounting the position sensor

1. Place the lever (1) on the sensor in

mid-position and hold it in place. Un-

thread the nut (1.1) and remove the lever

together with the disk spring (1.2) from

the sensor shaft.

2. Screw the position sensor (20) onto the

mounting plate (21).

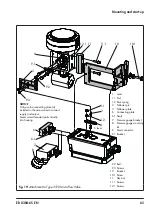

3. Depending on the actuator size and rat-

ed valve travel, determine which lever

and position of the follower pin (2) is to

be used from the travel table on

page 28. The positioner is delivered

with the

M

lever in pin position 35 on the

sensor. If necessary, remove the follower

pin (2) from its pin position and move it

to the hole for the recommended pin po-

sition and screw tight.

4. Place the lever (1) and disk spring (1.2)

on the sensor shaft. Place the lever

in

mid-position

and

hold it in place

. Screw

on the nut (1.1).

5. Place follower clamp (3) on the actuator

stem, align it and screw tight so that the

Note

Summary of Contents for TROVIS SAFE 3730-6

Page 12: ...12 EB 8384 6S EN...

Page 16: ...16 EB 8384 6S EN...

Page 22: ...22 EB 8384 6S EN...

Page 40: ...40 EB 8384 6S EN...

Page 42: ...42 EB 8384 6S EN...

Page 82: ...82 EB 8384 6S EN...

Page 90: ...90 EB 8384 6S EN...

Page 96: ...96 EB 8384 6S EN...

Page 132: ...132 EB 8384 6S EN...

Page 152: ...152 EB 8384 6S EN...

Page 155: ...EB 8384 6S EN 155...

Page 156: ...156 EB 8384 6S EN...

Page 157: ...EB 8384 6S EN 157...

Page 158: ...158 EB 8384 6S EN...

Page 159: ...EB 8384 6S EN 159...

Page 160: ...160 EB 8384 6S EN...

Page 161: ...EB 8384 6S EN 161...

Page 162: ...162 EB 8384 6S EN...

Page 163: ...EB 8384 6S EN 163...

Page 164: ...164 EB 8384 6S EN...

Page 165: ...EB 8384 6S EN 165...

Page 166: ...166 EB 8384 6S EN...

Page 167: ...EB 8384 6S EN 167...

Page 182: ...182 EB 8384 6S EN...

Page 183: ...EB 8384 6S EN 183...