6

Troubleshooting

7

Customer inquiries

Should you have any inquiries, please submit

the following details:

4

Type and nominal size of the valve

4

Threaded or flanged connection

4

Model number

4

Upstream and downstream pressures

4

Flow rate in m³/h

4

Has a strainer been installed?

4

Installation drawing

10

EB 3135-1 EN

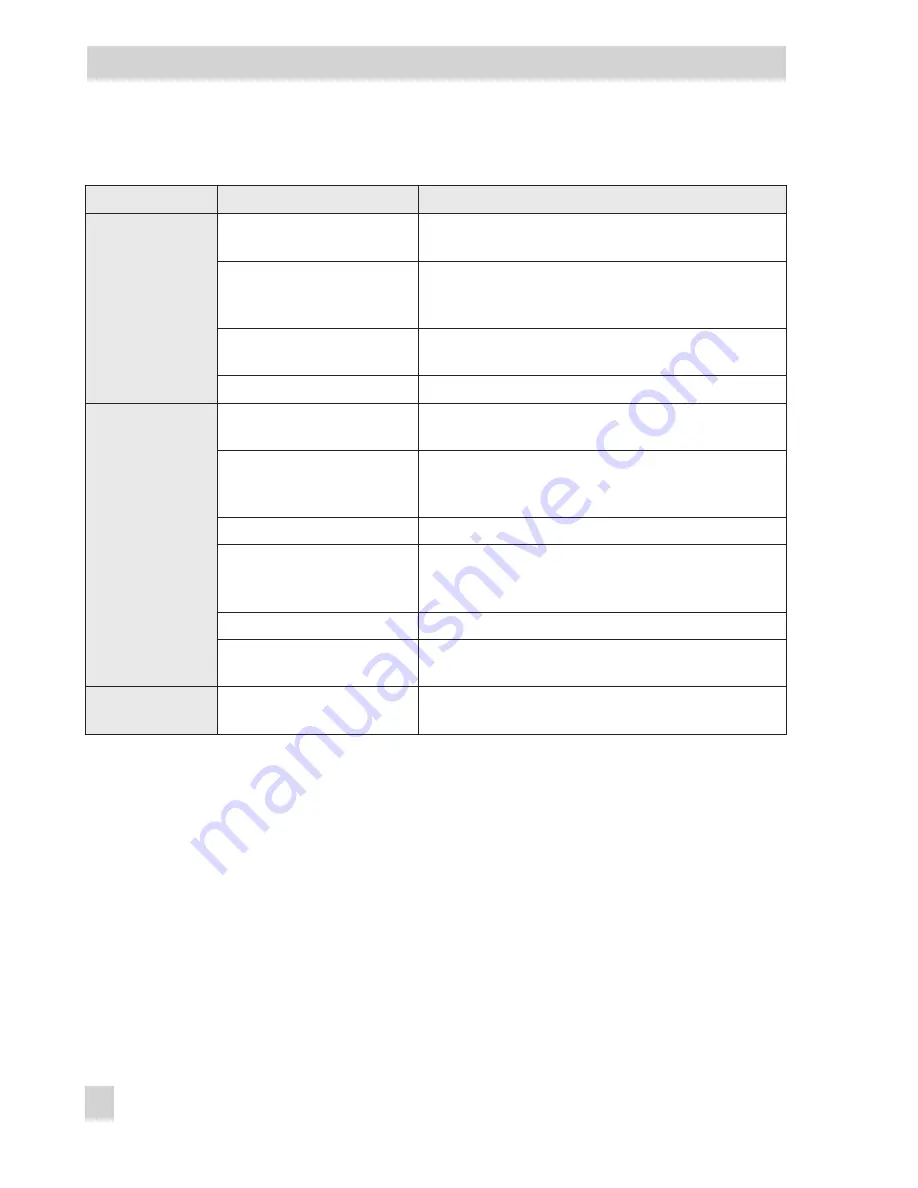

Troubleshooting

Fault

Possible causes

Solution

Flow rate

exceeds

adjusted set

point

Valve too large for

control task

Recalculate K

VS

and contact SAMSON.

Seat and plug leak

Remove valve, clean seat and plug. If necessary,

replace plug (section 4.2).

Otherwise, return device for repair.

Operating diaphragm

defective

Replace diaphragm (section 4.3) or return device

for repair.

Control line blocked

Remove and clean control line.

Flow set point

not reached

Incorrect set point range

selected

Check set point range and contact SAMSON.

Safety device, e.g. pressure

regulator, has been

triggered

Check plant, unlock safety device.

Electric actuator extended

Check control signal from the electric control device.

Insufficient pressure drop

across the plant

Compare existing differential pressure in the plant

with the plant’s drag.

Min. diff. pressure = special diff. pr ( /

)

.

V K

VS

2

Strainer blocked

Drain and clean filter of the strainer.

Valve installed against

direction of flow

Re-install valve such that direction of flow

corresponds to arrow on the body.

Control loop

hunts

Valve too large for

control task

Recalculate K

VS

and contact SAMSON.