3.2.2 Adjustment with Type 5824

Actuator

1. Retract the actuator stem by turning the

handwheel counterclockwise or by

applying a corresponding control signal

from the control device.

2. Continue as described in section 3.2.1.

3.2.3 Adjustment with Type 5825

Actuator

1. Switch the control device to manual mode

and change the control signal to retract

the actuator stem all the way and com-

press the spring mechanism.

EB 3135-1 EN

7

Operation

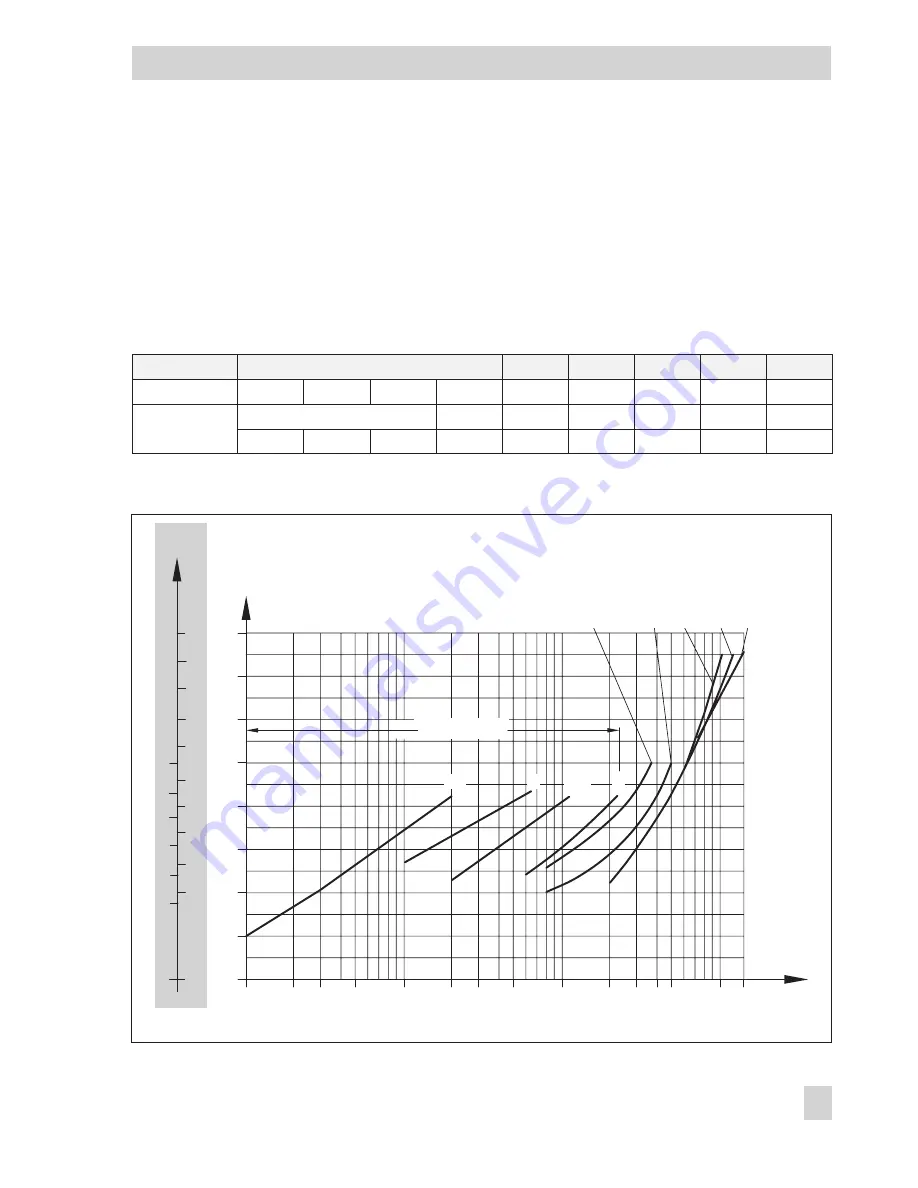

Fig. 3 · Diagram for adjusting the flow rate

0

3

4

5

5

6

10

12

0

9

4

3

2

DN 32 to 50

DN 15 to 25

6

7

11

0.01

0.05

0.1

0.5

1

5

10

1

0

2

3

4

5

6

7

8

DN 15, K

vs

...

32

40 50

V˚

m3/h

0.02 0.03

0.2 0.3

2

3 4

15

0.4

1

2.5

4

25

DN20

7

8

Turns of the set point screw

Nominal size

15

20

25

32

40

1)

50

1)

K

VS

0.4

1

2.5

4

6.3

8

12.5

16/20

2)

20/25

2)

Set point range

flow rate m³/h

0.6...1.3

3)

0.8...2.3

3)

0.8...3.5

3)

2...5.8

3)

3...9.1

3)

4...14.1

3)

0.03...0.2 0.1...0.64 0.2...1.2 0.6...2.5 0.8...3.6

0.8...5

2...10

3...12.5

4...15

1)

Also available as version with flanged body

2)

K

VS

for flanged body

3)

A higher noise level will occur if the specified set point values are exceeded