ENGLISH-12

Installing the unit

Recovery

f

When removing refrigerant from the system for servicing or decommissioning, it is recommended to remove the entire refrigerant.

f

When transferring refrigerant into cylinders, make sure that only the refrigerant recovery cylinders are used.

f

All cylinders used for the recovered refrigerant shall be labelled.

f

Cylinders shall be equipped with pressure relief valves and shut-off valves in a proper order.

f

The recovery system shall operate normally according to the specified instructions and shall be suitable for refrigerant recovery.

f

In addition, the calibration scales shall operate normally.

f

Hoses shall be equipped with leak-free disconnect couplings.

f

Before starting the recovery, check for the status of the recovery system and sealing state. Consult with the manufacturer if suspected.

f

The recovered refrigerant shall be returned to the supplier in the correct recovery cylinders with the Waste Transfer Note attached.

f

Do not mix refrigerants in the recovery units or cylinders.

f

If compressors or compressor oils are to be removed, make sure that they have been evacuated to the acceptable level to ensure

that flammable refrigerant does not remain in the lubricant.

f

The evacuation process shall be performed before sending the compressor to the suppliers.

f

Only the electrical heating to the compressor body is allowed to accelerate the process.

f

Oil shall be drained safely from the system.

f

Never install a motor-driven equipment to prevent ignition.

f

Empty recovery cylinders shall be evacuated and cooled before recovery.

Installation location requirements

f

The outdoor unit shall be installed in an open space that is always ventilated.

f

The local gas regulations shall be observed.

f

For installation inside a building (this applies either to indoor or outdoor units installed inside) a minimum room floor area of

space conditioned is mandatory according to IEC 60335-2-40:2018 (see the reference table into either the indoor or outdoor

unit installation manual).

f

To handle, purge, and dispose the refrigerant, or break into the refrigerant circuit, the worker should have a certificate from an

industry-accredited authority.

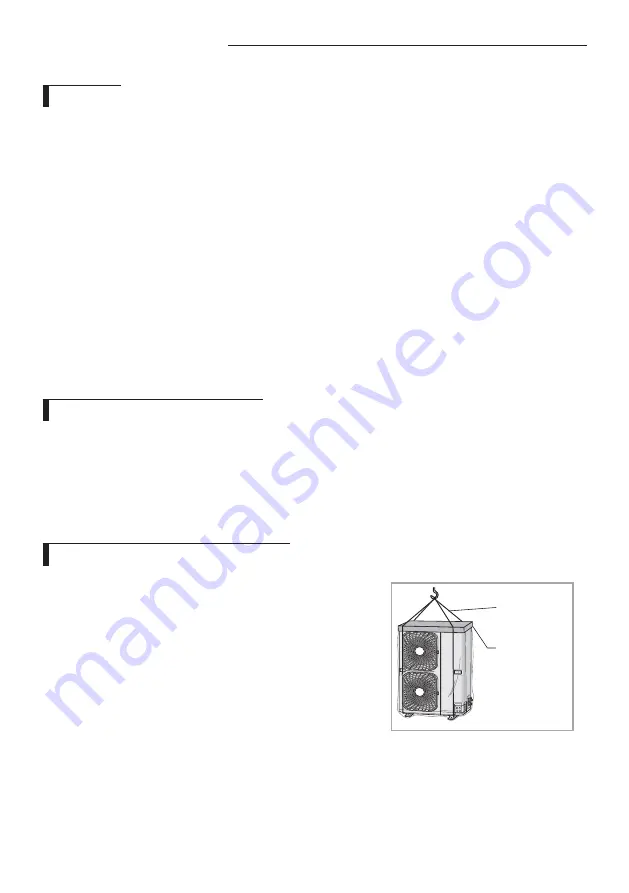

Moving the Outdoor Unit by Wire Rope

Fasten the outdoor unit by two 8 m or longer wire ropes as shown at the

figure. To prevent from damage or scratches, insert a piece of cloth between

the outdoor unit and rope, then move the unit.

❋

The appearance of the unit may be different from the picture depending

on the model.

Plate protection

cloth

Wire rope