5

English

Sa

fe

ty

In

fo

rm

at

io

n

CAUTION

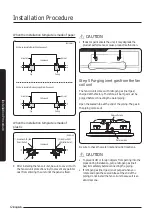

• Before starting the Installation, be sure to carefully

read this installation manual.

• Make sure that the product is transported to the

installation site with being packed. After reaching the

installation site, if you need to remove the package

and transport the product, use soft materials to

prevent damage to the product during transportation.

• Be sure to install the drain pipe according to the

installation manual so that the drainage is reliable.

– If the piping is installed incompletely, it may cause

water to penetrate indoors and household items to

get wet.

• Tighten the nuts using a torque wrench according to

the specified method.

– If the nuts are tightened too tightly, they may

break after a long period of time, leading to water

leakage.

• Wear gloves (thick gloves such as cotton work gloves)

during installation.

– Failure to do so may cause personal injury due to

parts.

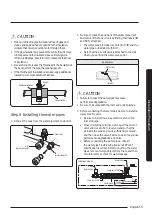

• Do not install or operate the fan coil unit in the

following places:

– Where there is a mixture of mineral oil or oil vapors

are generated, (If the oil is attached to the heat

exchanger, it may cause performance degradation,

spraying, or scattering of condensation. If the oil is

attached to plastic parts, it may cause deformation

or breakage to them. This may result in product

malfunction or water leakage.)

– Where corrosive gases such as sulfur gas are

present (Because copper pipes and brazed parts

may be corroded in these places, additional

corrosion protection and rust preventive

application are required. Contact a facility

specialist.)

– Where exposed to combustible gas, carbon fiber,

flammable powder, or dust, or where volatile

combustion gases such as thinner or gasoline are

used (Gases near the fan coil unit may ignite.)

– Where electromagnetic interferences are

generated (The control unit may not operate.)

– Where the air contains a high level of salinity,

such as near the sea, or where voltage fluctuates

significantly, such as in factories, or in vehicles or

ships,

– Where obstacles that disturb the air flow, such as

ventilation openings or lighting fixtures, are near

the product (The disturbed air flow may cause

performance degradation or stopping of the unit.)

– Where a special spray is used frequently.

– Do not install the product in a hair salon or other

similar places because hairspray ingredients may

reduce the hydrophilic property in product's heat

exchange, causing condensation on the panel and

the air flow blades in the Cool mode.

– Where fine powder is used (baking room, etc.)

– Do not use the product for unintended purposes,

such as preservation of precision equipment, foods,

animals, plants, cosmetics, art works, etc. (Failure

to do so may cause property damage.)

– Where corrosive gases such as sulfur dioxide are

generated, such as toilet exhausts or vent outlets

(Because copper pipes and brazed parts may be

corroded in these places, additional corrosion

protection and rust preventive application are

required. Contact a facility specialist.)

– Where flammable gases may leak, carbon fiber or

flammable dust floats, or other volatile flammable

materials such as thinner and gasoline are treated

(If gas leaks and remains around the product, it

may cause ignition.)

– Where the fan coil unit may be corroded, such as

coastal areas and hot springs.

Summary of Contents for AGTN1DKH Series

Page 41: ...41 English Appendix Memo ...

Page 42: ...42 Memo English Appendix ...

Page 43: ...43 English Appendix ...

Page 44: ...DB68 09309A 00 ...