34

English

Extr

a Pr

oc

edur

es

Extra Procedures

Extra procedures

Pumping down refrigerant

WARNING

•

After installing the product, be sure to perform leak

tests on the piping connections. After pumping down

refrigerant to inspect or relocate the outdoor unit,

be sure to stop the compressor and then remove the

connected pipes.

‐

Do not operate the compressor while a valve is

open due to refrigerant leakage from a pipe or an

unconnected or incorrectly connected pipe. Failure

to do so may cause air to flow into the compressor

and too a high pressure to develop inside the

refrigerant circuit, leading to an explosion or

product malfunction.

Pump-down is an operation intended to collect all the

system refrigerant in the outdoor unit.

This operation must be carried out before disconnecting

the refrigerant pipe in order to avoid refrigerant loss to

the atmosphere.

1

Turn the system on in cooling with fan operating at

high velocity and then let the compressor run for more

than 5 minutes. (Compressor will immediately start,

provided 3 minutes have elapsed since the last stop.)

2

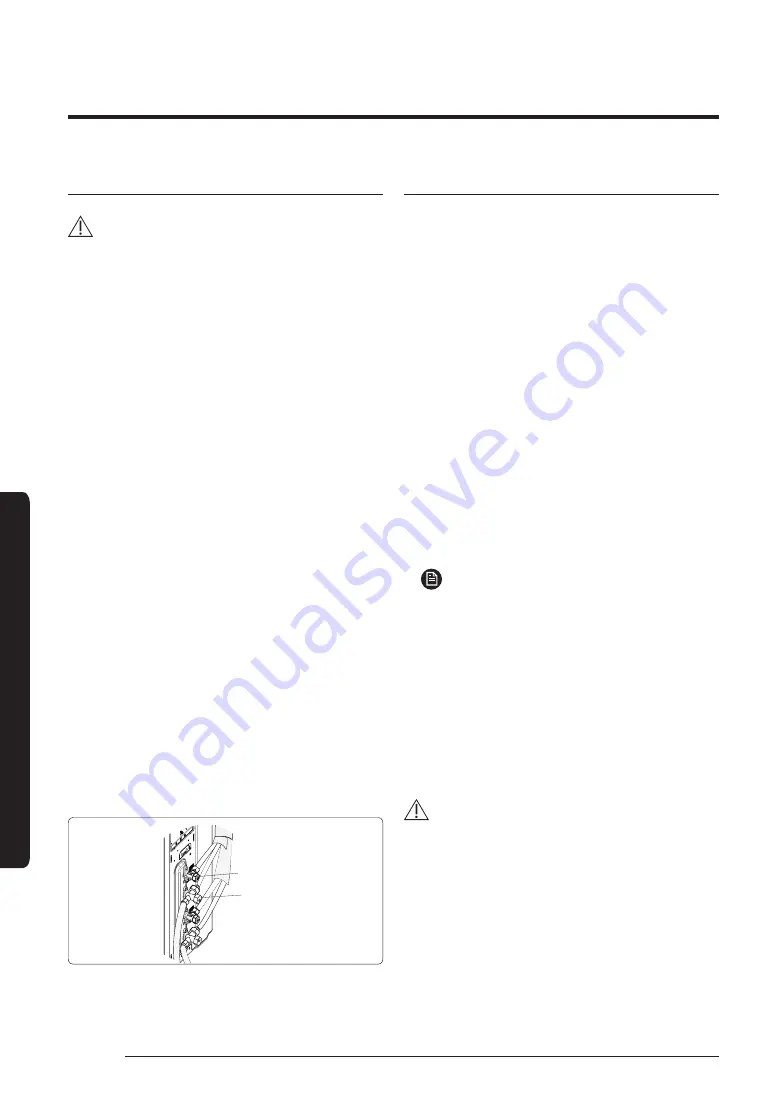

Release the valve caps on High and Low pressure side.

3

Use L-wrench to close the valve on the high pressure

side.

4

After approximately 2 minute, close the valve on the

low pressure side.

5

Stop operation of the air conditioner by pressing the

(Power) button on the indoor unit or remote control.

6

Disconnect the pipes.

Relocating the indoor and outdoor units

1

Pump down refrigerant. See

Pumping down

refrigerant

on page 34.

2

Remove the power cord.

3

Disconnect the assembly cable from the indoor and

outdoor units.

4

Remove the flare nuts connecting the indoor units and

the pipes. At this time, cover the pipes of the indoor

unit and the other pipes using a cap or vinyl plug to

avoid foreign material entering.

5

Disconnect the pipes connected to the outdoor units.

At this time, cover the valve of the outdoor units and

the other pipes using a cap or vinyl plug to avoid

foreign material entering.

Note: Make sure you do not bend the connection pipes in

the middle and store together with the cables.

6

Move the indoor and outdoor units to a new location.

7

Remove the mounting plate for the indoor unit and

move it to a new location.

NOTE

•

Before relocating the units, be sure to thoroughly read

Recovery

on page 6.

•

When recharging R-32 refrigerant after it has been

completely removed, be sure to charge only the factory

refrigerant amount.

•

When vacuuming the product, be sure to proceed for

at least 1 hour.

•

Be sure to use an electronic balance when measuring

the amount of refrigerant, and make sure that only the

specified amount is charged.

CAUTION

•

If more than the amount of refrigerant specified on the

label is charged, a fire may occur when the refrigerant

leaks.

A(Gas)

B(Liquid)

Summary of Contents for AJ NCJ2EG Series

Page 38: ......