Product Specifications

Samsung Electronics

2-5

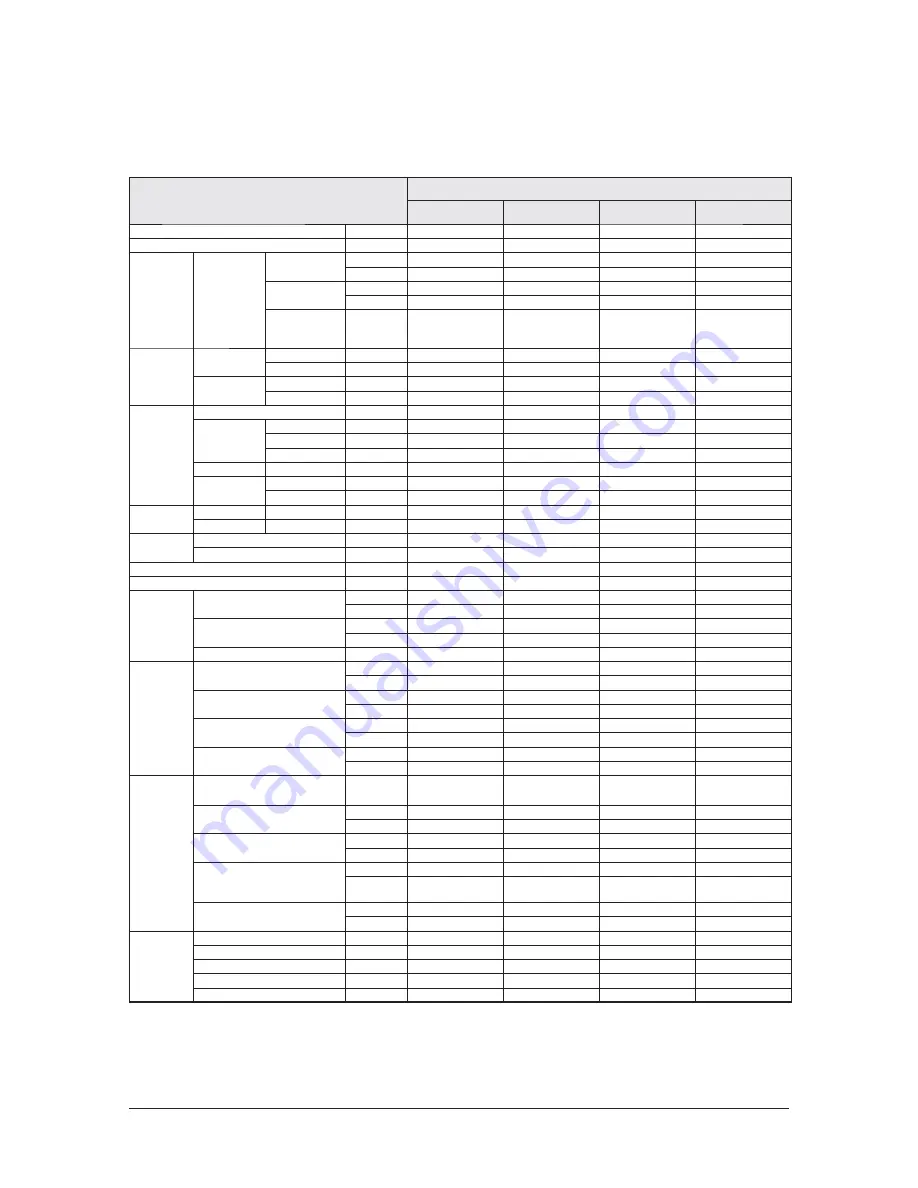

Indoor Unit(cont.)

Q

4WAY casette (Small)

Model

4WAY casette - Small

AM009FN4DCH/AA

AM012FN4DCH/AA

AM018FN4DCH/AA

AM024FN4DCH/AA

Power Supply

ø, #, V, Hz

1,2,208-230,60

1,2,208-230,60

1,2,208-230,60

1,2,208-230,60

Mode

-

HP/HR

HP/HR

HP/HR

HP/HR

Performance

Capacity

(Nominal)

Cooling 2)

kW

-

-

-

-

Btu/h

9,000

12,000

18,000

24,000

Heating 2)

kW

-

-

-

-

Btu/h

10,000

13,500

20,000

27,000

Condensate

(with high fan

speed)

Liter/h

-

-

-

-

Power

Power Input

(Nominal)

Cooling 1)

W

32

32

32

40

Heating 2)

-

32

32

32

40

Current Input

(Nominal)

Cooling 1)

A

0.25

0.25

0.25

0.3

Heating 2)

-

0.25

0.25

0.25

0.3

Fan

Type

-

Turbo Fan

Turbo Fan

Turbo Fan

Turbo Fan

Motor

Model

-

FMC6531SSH

FMC6531SSH

FMC6531SSH

FMC6531SSH

Type

-

BLDC

BLDC

BLDC

BLDC

Output x n

W

65 x 1

65 x 1

65 x 1

65 x 1

Air Flow Rate

H/M/L

CMM

15.50 / 14.00 / 12.00

15.50 / 14.00 / 12.00

15.50 / 14.00 / 12.00

17.50 / 16.00 / 14.00

External Pressure

Min / Std / Max

Pa

-

-

-

-

-

WG

-

-

-

-

Sound

Sound Pressure

High / Mid / Low

dBA

-

-

-

-

Sound Power

High / Mid / Low

-

-

-

-

Refrigerant

Type

-

R-410A

R-410A

R-410A

R-410A

Control Method

-

EEV INCLUDED

EEV INCLUDED

EEV INCLUDED

EEV INCLUDED

Temperature Control

-

Micom&Thermistors

Micom&Thermistors

Micom&Thermistors

Micom&Thermistors

Safety devices

-

Fuse

Fuse

Fuse

Fuse

Piping

Connections

Liquid Pipe (Flare)

ø,mm

6.35

6.35

6.35

9.52

ø, inch

1/4

1/4

1/4

3/8

Gas Pipe (Flare)

ø,mm

12.7

12.7

12.7

15.88

ø, inch

1/2

1/2

1/2

5/8

Drain Pipe (Quick lock)

ø,mm

VP25 (OD32,ID25)

VP25 (OD32,ID25)

VP25 (OD32,ID25)

VP25 (OD32,ID25)

Dimensions

Net Weight

kg

15.00

15.00

15.00

15.00

lbs

33.07

33.07

33.07

33.07

Shipping Weight

kg

18.50

18.50

18.50

18.50

lbs

40.79

40.79

40.79

40.79

Net Dimensions (W×H×D)

mm

840 x 204 x 840

840 x 204 x 840

840 x 204 x 840

840 x 204 x 840

inch

33.07 x 8.03 x 33.07

33.07 x 8.03 x 33.07

33.07 x 8.03 x 33.07

33.07 x 8.03 x 33.07

Shipping Dimensions (W×H×D)

mm

898 x 275 x 898

898 x 275 x 898

898 x 275 x 898

898 x 275 x 898

inch

35.35 x 10.83 x 35.35

35.35 x 10.83 x 35.35

35.35 x 10.83 x 35.35

35.35 x 10.83 x 35.35

Panel Size

Panel model

-

PC4NUSKFN

PC4NUSKFN

PC4NUSKFN

PC4NUSKFN

Panel Net Weight

kg

5.80

5.80

5.80

5.80

lbs

12.79

12.79

12.79

12.79

Shipping Weight

kg

8.40

8.40

8.40

8.40

lbs

18.52

18.52

18.52

18.52

Net Dimensions (W×H×D)

mm

950 x 45 x 950

950 x 45 x 950

950 x 45 x 950

950 x 45 x 950

inches

37.40 x 1.77 x 37.40

37.40 x 1.77 x 37.40

37.40 x 1.77 x 37.40

37.40 x 1.77 x 37.40

Shipping Dimensions (W×H×D)

mm

1,005 x 100 x 1,005

1,005 x 100 x 1,005

1,005 x 100 x 1,005

1,005 x 100 x 1,005

inch

39.57 x 3.94 x 39.57

39.57 x 3.94 x 39.57

39.57 x 3.94 x 39.57

39.57 x 3.94 x 39.57

Functions

Auto restart

-

O

O

O

O

Auto swing

-

O

O

O

O

Group/individual control

-

O

O

O

O

External contact control

-

O

O

O

O

Trouble shooting by LED

-

O

O

O

O