T

ro

u

b

l

eshootin

g

S

a

m

s

u

n

g

El

e

c

troni

c

s

4-10

3

4-4-59

:

C

o

mp

.

D

o

wn by C

o

mp

ressio

n R

atio

C

o

n

tro

l

1

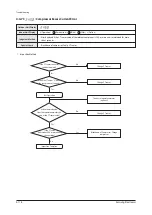

.

C

a

u

se

o

f

pro

b

l

e

m

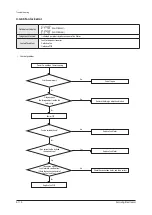

Y

es

A

re

the

4W

a

y V

a

lv

e

nor

m

a

lly

operatin

g

?

A

re

the

I

ndoor

U

nit

and

Ou

tdoor

U

nit

EEV

nor

m

a

lly

operatin

g

?

I

s

c

u

rrent

o

f

c

o

m

pressor

nor

m

a

lly?

C

o

m

p

l

ete

C

o

mm

issionin

g

R

ep

l

a

c

e

de

f

e

c

ti

v

e

sensor

C

he

ck

the

4W

a

y V

a

lv

e

C

he

ck

the

re

l

e

v

ant

EEV

C

o

m

pressor

I

nspe

c

tion

C

he

ck

the

re

f

ri

g

erant

Y

es

Y

es

No

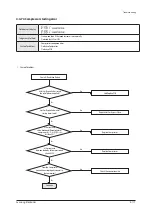

I

s

the

S-

net

esti

m

ated

v

a

lu

e

and

the

Mani

f

o

l

d

G

a

u

g

e

v

a

lu

e

in

ran

g

e

?

C

onne

c

t

S-

net

and

Mani

f

o

l

d

G

a

u

g

e

.

(

essentia

l

re

qu

ire

m

ent

)

No

No

No

No

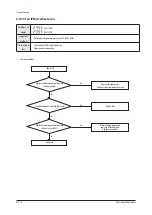

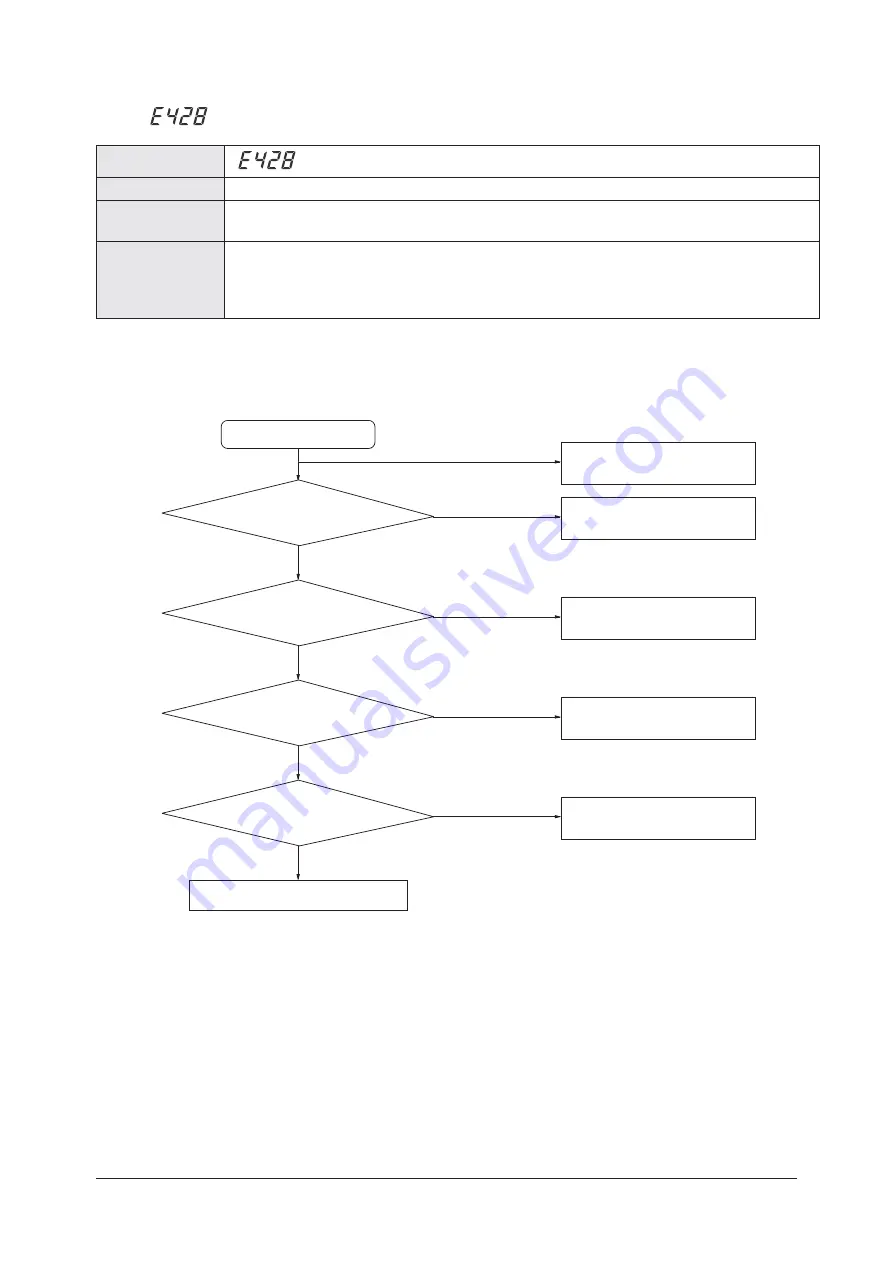

Ou

tdoor

u

nit

disp

l

a

y

I

ndoor

u

nit

disp

l

a

y

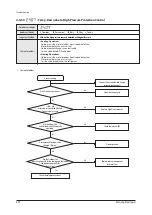

×(O

peration

)

ስ

(

R

eser

v

ation

)

ስ

(Bl

ast

)

ስ

(F

i

l

ter

)

×(

De

f

rost

)

Ju

d

g

m

ent

Method

∙ W

hen

c

o

m

pression

ratio

(

hi

g

h

press

u

re

+1

)

/(l

o

w

press

u

re

+1

)

l

ess

than

1

.

5

and

l

asts

f

or

10

m

in

u

tes

or

m

ore

∙

Di

ff

erentia

l

press

u

re

(

hi

g

h

press

u

re

- l

o

w

press

u

re

)

l

ess

than

0

.

4

MPa

.g

and

l

asts

f

or

10

m

in

u

tes

or

m

ore

C

a

u

se

o

f

pro

b

l

e

m

∙ I

ndoor

and

Ou

tdoor

EEV

b

rea

k

do

w

n

∙ 4W

a

y V

a

lv

e

b

rea

k

do

w

n

∙ H

i

g

h

and

L

o

w

press

u

re

sensor

de

f

e

c

ti

v

e

∙

R

e

f

ri

g

erant

shorta

g

e