13

English

Instal

lation Pr

oc

edur

e

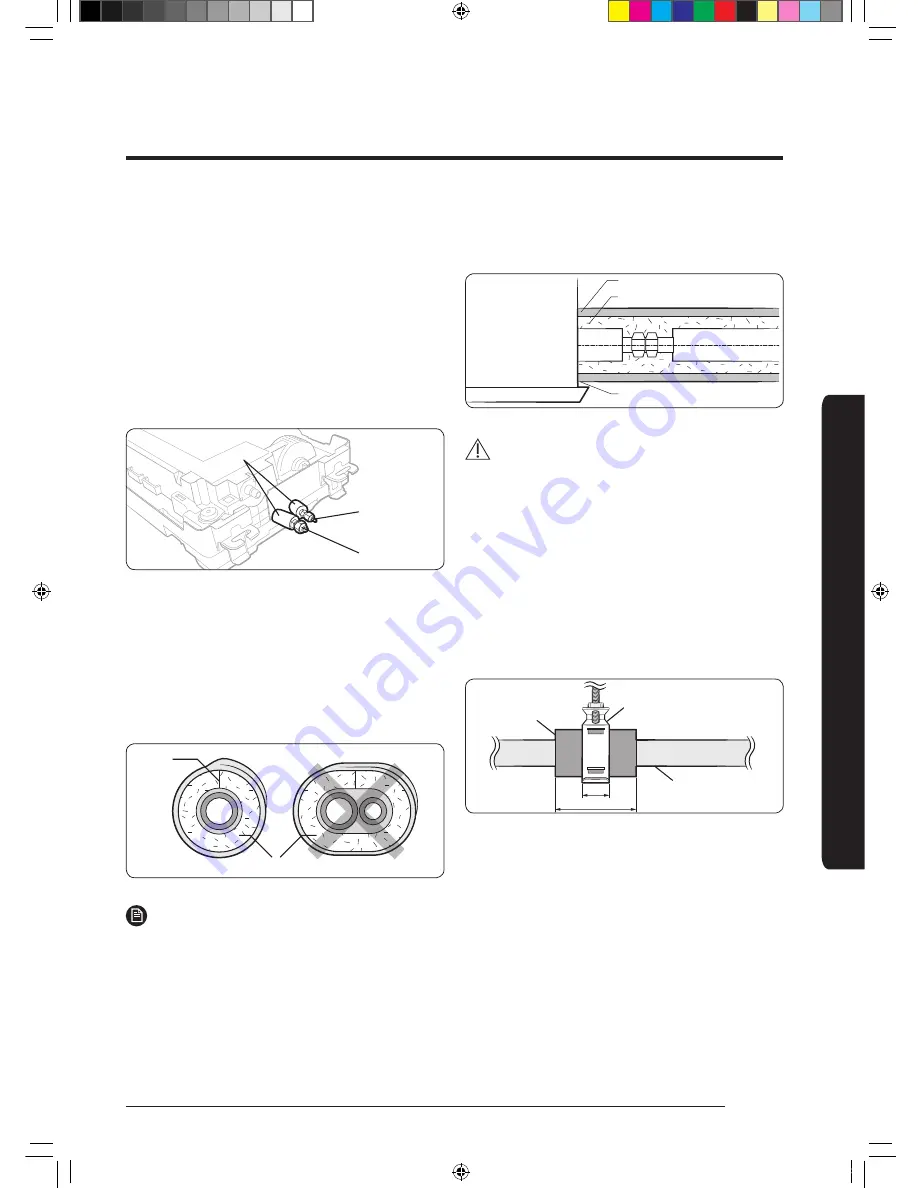

Step 8 Performing the gas leak test

To identify potential gas leaks on the indoor unit, inspect

the connection area of each refrigerant pipe using a leak

detector for R-410A.

Before recreating the vacuum and recirculating the

refrigerant gas, pressurize the whole system with

nitrogen (using a cylinder with a pressure reducer) at a

pressure above 4.1 MPa in order to immediately detect

leaks on the refrigerant fittings.

Made vacuum for 15 minutes and pressurizing system

with nitrogen.

Liquid side

Gas side

Insulator

Step 9 Insulating the refrigerant pipes

Once you have checked that there are no leaks in the

system, you can insulate the piping and hose.

1

To avoid condensation problems, place Acrylonitrile

Butadien Rubber separately around each refrigerant

pipe.

No gap

NBR (T13.0 or thicker)

NOTE

•

Always make the seam of pipes face upwards.

2

Wind insulating tape around the pipes and drain hose

avoiding compressing the insulation too much.

3

Finish wrapping insulating tape around the rest of the

pipes leading to the outdoor unit.

4

The pipes and electrical cables connecting the indoor

unit with the outdoor unit must be fixed to the wall

with suitable ducts.

Insulation cover pipe

Insulation pipe

Be sure to overlap the insulation.

Indoor unit

CAUTION

•

Must fit tightly against body without any gap.

•

Install the insulation not to get wider and use the

adhesives on the connection part of it to prevent

moisture from entering.

•

Wind the refrigerant pipe with insulation tape if it is

exposed to outside sunlight.

•

Install the refrigerant pipe respecting that the

insulation does not get thinner on the bent part or

hanger of pipe.

•

Add the additional insulation if the insulation plate

gets thinner.

Refrigerant pipe insulation

Hanger

Additional

insulation

a

a x 3

•

Must fit tightly against body without any gap.

•

All refrigerant connection must be accessible, in order

to permit either unit maintenance or removal.

DVM TK Wind-Free 1way IM EN_DB68-07553A-00.indb 13

2017-12-01 오후 2:19:02