Samsung Electronics

4-11

No

Parts

Procedure

Remark

1

ERV

(Energy Recovery

Ventilator)

1) Stop the air conditioner operation and

shut off the main power.

2) Remove the unit from ceiling suspension.

(Disassembly is not required when Fan,

Motor, Element, Filter replacement or

cleaning.)

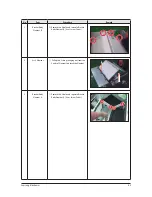

2

Ass’y Cabi

Cover Element

1) Remove the 3 bolts on Cover Element to

detach it.(Use +Screw Driver.)

2) Loosen the clips connected to the Cover.

3) Separate the connector connected to the

Damper by pulling out the connector body.

Q

Product Disassembly (while still being installed)