Troubleshooting

Samsung Electronics

4-85

4-3-47

,

: Prohibition of the operation of Compressor due to OoutdoorTemperature

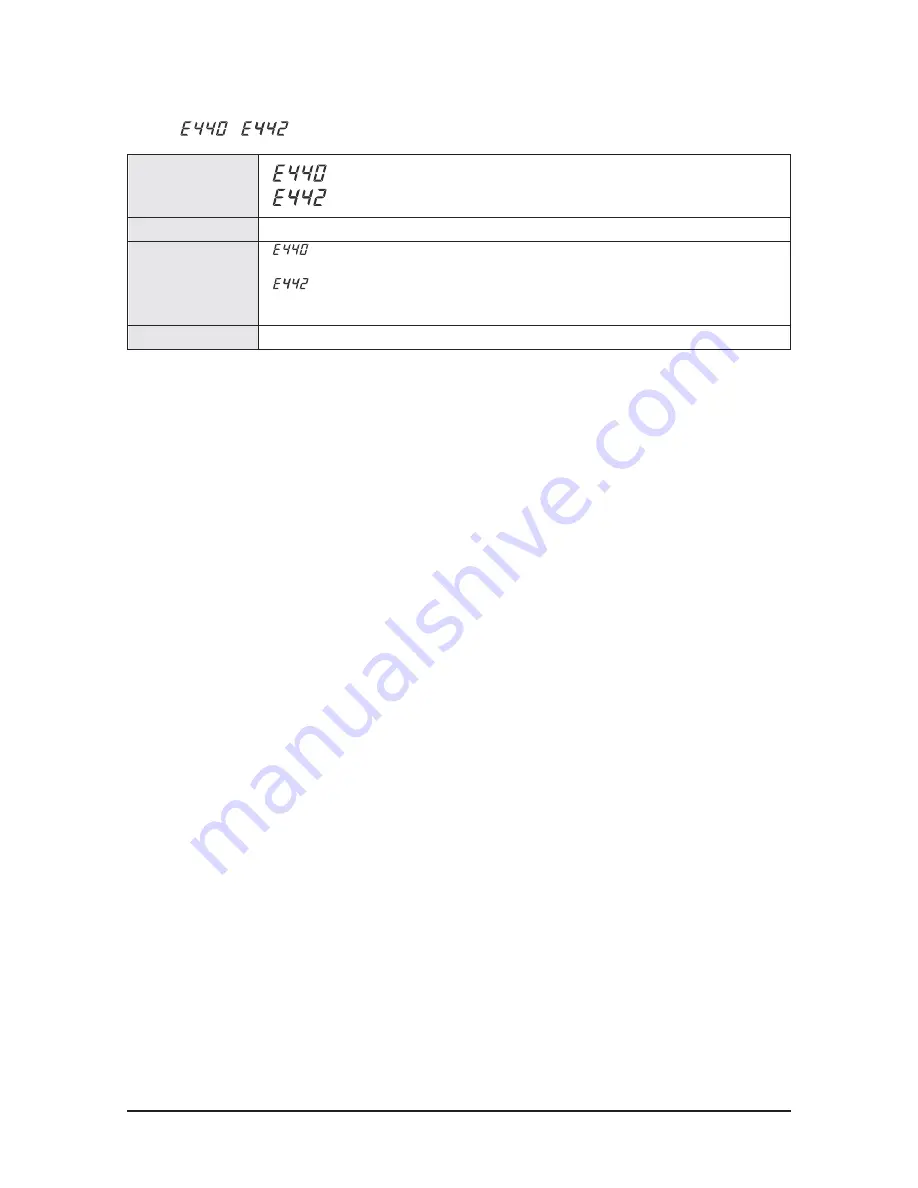

Indoor unit display

Cause of problem

No sign

• Operation Prohibition mode by the indoor temperature limit

Criteria

:

Right before an outdoor unit starts heating operation by On signal of an indoor Remocon, the error

occurs and prohibits the operation in outdoor temperature over 86°/30°C

:

Right before operating heat refrigerant filling mode by the K1 switch of an outdoor PCB, the error

occurs and prohibits the operation in outdoor temperature over 59°F/15°C

Outdoor unit display

1. How to check

The above error code is not caused by a product’s problem but a function to protect the product by limiting the available tempera-

ture range so please refer to the usable temperature range in the product manual.

If the error code is displayed despite a condition that does not belong to any of the above diagnosis methods, read the temperature

sensor value of the outdoor inlet air with View Mode or S-net, and if the actual outdoor temperature is different, please replace the

temperature sensor.

(prohibit heating operation in outdoor temperature over 86°F/30°C)

(prohibit heat filling operation in outdoor temperature over 59°F/15°C)

Summary of Contents for AVXCSH023/032/040CE

Page 114: ...0 02 Samsung Electronics 4 30...

Page 232: ...0 02 Samsung Electronics 5 20...

Page 250: ...0 02 Samsung Electronics 5 38...

Page 262: ...0 02 Samsung Electronics 5 50...

Page 263: ...5 51 Samsung Electronics 5 2 Outdoor Unit 5 2 1 RVXVHT075 100FE RD075 100VHXFA...

Page 264: ...Exploded Views and Parts List Samsung Electronics 5 52 RVXVHT075 100FE RD075 100VHXFA cont...

Page 267: ...Exploded Views and Parts List 5 55 Samsung Electronics 5 2 2 RVXVHT125FE RD125VHXFA...

Page 268: ...Exploded Views and Parts List Samsung Electronics 5 56 RVXVHT125FE RD125VHXFA cont...

Page 279: ...Exploded Views and Parts List 5 67 Samsung Electronics 5 2 5 RD040 050MHXCA...

Page 285: ...PCB Diagram 6 5 Samsung Electronics 6 1 4 Duct type Slim MAIN PCB...

Page 288: ...0 02 Samsung Electronics 6 8...

Page 289: ...PCB Diagram 6 9 Samsung Electronics 6 1 5 Duct type MSP MAIN PCB...

Page 291: ...PCB Diagram 6 11 Samsung Electronics 6 1 6 Duct type BIG MAIN PCB...

Page 295: ...PCB Diagram 6 15 Samsung Electronics 6 1 7 Wall mounted type Neo Forte without EEV MAIN PCB...

Page 298: ...0 02 Samsung Electronics 6 18...

Page 299: ...PCB Diagram 6 19 Samsung Electronics 6 1 8 Wall mounted type Neo Forte with EEV MAIN...

Page 302: ...0 02 Samsung Electronics 6 22...

Page 303: ...PCB Diagram 6 23 Samsung Electronics 6 1 9 Wall mounted type Vivace MAIN PCB...

Page 332: ...0 02 Samsung Electronics 7 16...