TYPES

TRAY 1

OPTIONAL

TRAY

MULTI-PURPOSE

TRAY

Plain

Ɣ

Ɣ

Ɣ

Thick

Ɣ

Ɣ

Ɣ

Thicker

Ɣ

Extra Thick

Ɣ

Thin

Ɣ

Ɣ

Ɣ

Cotton

Ɣ

Ɣ

Ɣ

Color

Ɣ

Ɣ

Ɣ

Preprinted

Ɣ

Ɣ

Ɣ

Recycled

Ɣ

Ɣ

Ɣ

Envelope

Ɣ

Transparency

Ɣ

Labels

Ɣ

CardStock

Ɣ

Bond

Ɣ

Archive

Ɣ

Glossy Photo

Ɣ

Media and tray

_ 39

(

Ɣ

: Supported, Blank: Not supported)

The media types are shown in the

Printing Preferences

. This paper type

option allows you to set the type of paper to be loaded in the tray. This

setting appears in the list, so that you can select it. This will let you get the

best quality printout. If not, the desired print quality may not be achieved.

•

Plain:

60 to 90 g/m

2

(16 to 24 lb.) Normal plain paper.

•

Thick:

90 to 105 g/m

2

(24 to 28 lb.) thick paper.

•

Thicker:

106 to 120 g/m

2

(28 to 32 lb.) thicker paper.

•

Thin:

60 to 70 g/m

2

(16 to 19 lb.) thin paper.

•

Cotton:

75 to 90 g/m

2

(20 to 24 lb.) cotton paper.

•

Color:

75 to 90 g/m

2

(20 to 24 lb.) color-backgrounded paper.

•

Preprinted:

75 to 90 g/m

2

(20 to 24 lb.) preprinted/letterhead paper.

•

Recycled:

60 to 90 g/m

2

(16 to 24 lb.) recycled paper.

When you use recycled paper as a used paper, printouts might be

wrinkled.

•

Envelope:

75 to 90 g/m

2

(20 to 24 lb.) envelope.

•

Transparency:

138 to 146 g/m

2

(37 to 39 lb.) transparency paper.

•

Labels:

120 to 150 g/m

2

(32 to 40 lb.) label.

•

Extra Thick:

106 to 170 g/m

2

(28 to 46 lb.) extra thick.

•

CardStock:

171 to 220 g/m

2

(46 to 59 lb.) cardstock.

•

Bond:

105 to 120 g/m

2

(28 to 32 lb.) bond.

•

Archive:

70 to 90 g/m

2

(19 to 24 lb.) If you need to keep the print-out for

a long period time, such as archives, select this option.

•

Glossy Photo:

111 to 130 g/m

2

(30 to 35lb.), 131 to 175 g/m

2

(35 to

47lb.), 176 to 220 g/m

2

(47 to 59lb.)glossy photo paper.

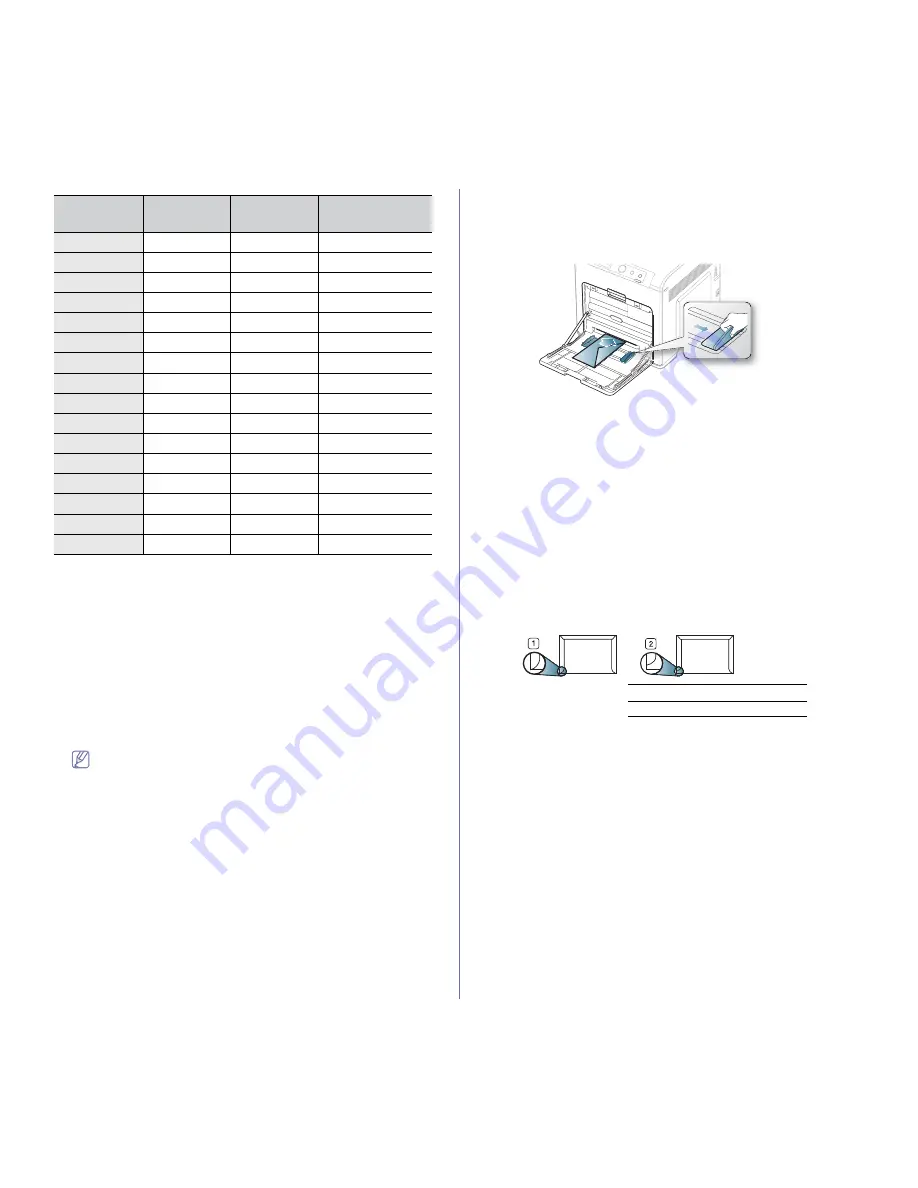

Envelope

Successful printing on envelopes depends upon the quality of the

envelopes.

To print an envelope, place it flap side up with the stamp area bottom the

top right side.

•

When selecting envelopes, consider the following factors:

-

Weight:

The weight of the envelope paper should not exceed

90 g/m

2

otherwise, jam may occur.

-

Construction:

Prior to printing, envelopes should lie flat with less

than 6 mm curl, and should not contain air.

-

Condition:

Envelopes should not be wrinkled, nicked, nor

damaged.

-

Temperature:

Use envelopes that are compatible with the heat and

pressure of the machine during operation.

•

Use only well-constructed envelopes with sharp-and well-creased folds.

•

Do not use stamped envelopes.

•

Do not use envelopes with clasps, snaps, windows, coated lining,

self-adhesive seals, or other synthetic materials.

•

Do not use damaged or poorly made envelopes.

•

Be sure the seam at both ends of the envelope extends all the way to

the corner of the envelope.

1

Acceptable

2

Unacceptable

•

Envelopes with a peel-off adhesive strip or with more than one flap that

folds over to seal must use adhesives compatible with the machine’s

fusing temperature about 170°C(338 °F) for 0.1 second. The extra flaps

and strips might cause wrinkling, creasing, or jams, and may even

damage the fuser.

•

For the best print quality, position margins no closer than 15 mm (0.59

inches) from the edges of the envelope.

•

Avoid printing over the area where the envelope’s seams meet.