Troubleshooting

_ 244

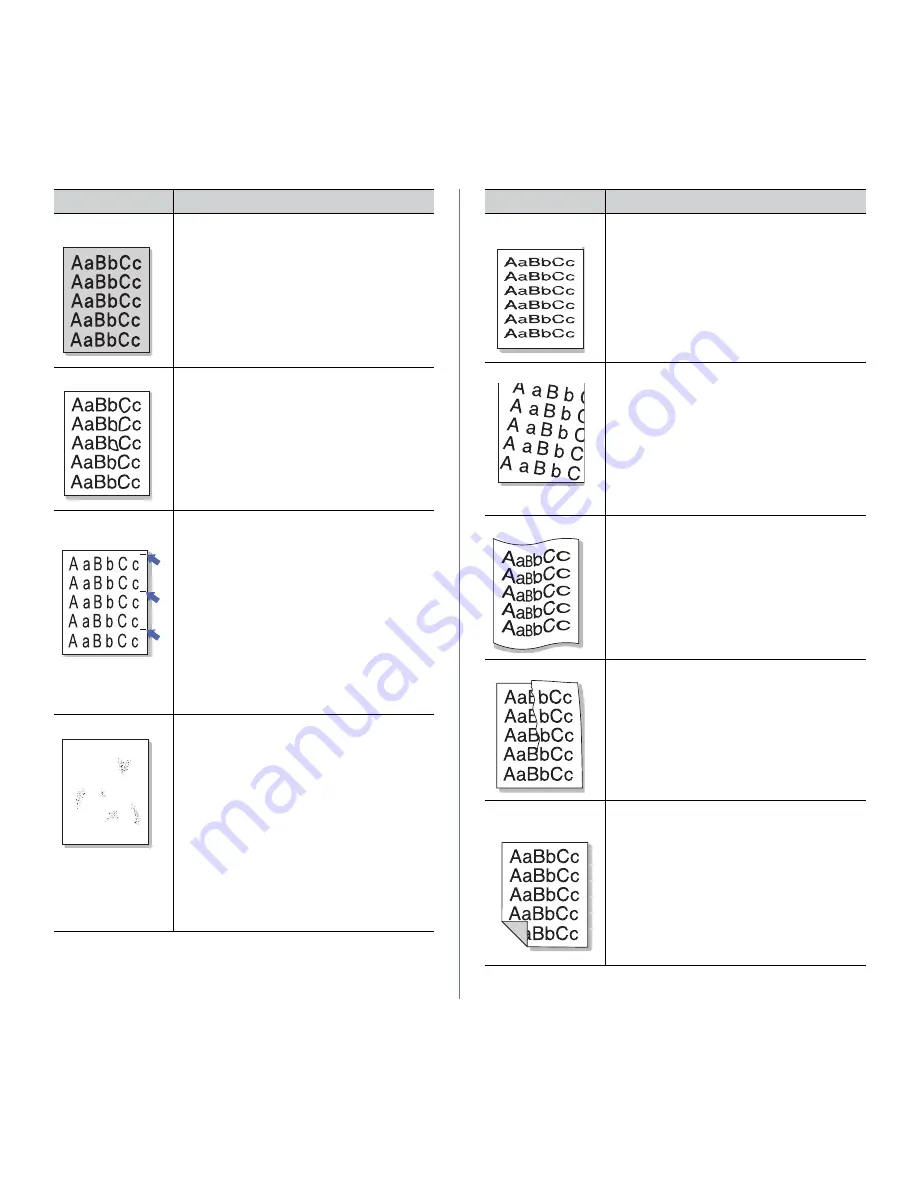

Color or Black

background

If the amount of background shading becomes

unacceptable:

•

Change the image transfer belt if it has

reached its lifespan. Contact a service

representative.

•

Check the environmental conditions: very dry

conditions (low humidity) or a high level of

humidity (higher than 80% RH) can increase

the amount of background shading.

•

Remove the old toner cartridge and install a

new one.

Toner smear

If toner smears on the page:

•

Clean the inside of the machine. Cleaning the

inside or contact a service representative.

•

Check the paper type and quality (see "Print

media specifications" on page 252).

•

Remove the imaging unit and install a new

one. Contact a service representative.

•

Change the image transfer belt if it has

reached its lifespan. Contact a service

representative.

Vertical repetitive

defects

If marks repeatedly appear on the printed side of

the page at even intervals:

•

The imaging unit may be damaged. If a

repetitive mark occurs on the page, run a

cleaning sheet through several times to clean

the imaging unit. Cleaning the inside. If you

still have the same problems, remove the

imaging unit and install a new one. Contact a

service representative.

•

Parts of the machine may have toner on them.

If the defects occur on the back of the page,

the problem will likely correct itself after a few

more pages.

•

The fusing assembly may be damaged.

Contact a service representative.

Background scatter

Background scatter results from bits of toner

randomly distributed on the printed page.

•

The paper may be too damp. Try printing with

a different batch of paper. Do not open

packages of paper until necessary so that the

paper does not absorb too much moisture.

•

If background scatter occurs on an envelope,

change the printing layout to avoid printing

over areas that have overlapping seams on

the reverse side. Printing on seams can cause

problems.

•

If background scatter covers the entire

surface area of a printed page, adjust the print

resolution through your software application or

in

Printing Preferences

(see "Opening

printing preferences" on page 140).

Condition

Suggested Solutions

A

Misformed

characters

•

If characters are improperly formed and

producing hollow images, the paper stock may

be too slick. Try different paper (see "Print

media specifications" on page 252).

•

If characters are improperly formed and

producing a wavy effect, the scanner unit may

need service. Cleaning the scan unit or contact

a service representative.

Page skew

•

Ensure that the paper is loaded properly.

•

Check the paper type and quality (see "Print

media specifications" on page 252).

•

Ensure that the paper or other material is

loaded correctly and the guides are not too

tight or too loose against the paper stack.

•

Ensure that the standard tray right bottom door,

dual cassette feeder right bottom door or high

capacity feeder right bottom door is securely

closed. If the bottom doors are not completely

closed, open and close the bottom doors.

Curl or wave

•

Ensure that the paper is loaded properly.

•

Check the paper type and quality. Both high

temperature and humidity can cause paper curl

(see "Print media specifications" on page 252).

•

Turn the stack of paper over in the tray. Also try

rotating the paper 180° in the tray.

Wrinkles or creases

•

Ensure that the paper is loaded properly.

•

Check the paper type and quality (see "Print

media specifications" on page 252).

•

Turn the stack of paper over in the tray. Also try

rotating the paper 180° in the tray.

•

Ensure that the standard tray right bottom door,

dual cassette feeder right bottom door or high

capacity feeder right bottom door is securely

closed. If the bottom doors are not completely

closed, open and close the bottom doors.

Back of printouts

are dirty

Check for leaking toner. Clean the inside of the

machine. Cleaning the inside or contact a service

representative.

Condition

Suggested Solutions