Fault

CODES

DESCRIPTION SUSPECT

Technical Description

Temperature Sensor error

TE1

Thermister

Main PCB

Thermister terminal not connected

Possible defect : Thermistor , Main PBA

Heater error

HE

Open Heater

Heater Relay

Main PCB

Heater terminal not connected Possible defect : Main Wire-Harness, open

Heater or Heater Relay, Main PBA

High temperature

Heating error.

HE1

Heater relay

Main PCB

Thermister

Water temperature sensed above 176F during operation Possible defect :

Thermistor , Main PBA or shorted heater relay

Low-level water error

9E

Low level Sensor

Level sensor fails to close after 1.2 gallons of water is metered in. If water is

present check for level sensor float stuck in empty position or bad switch

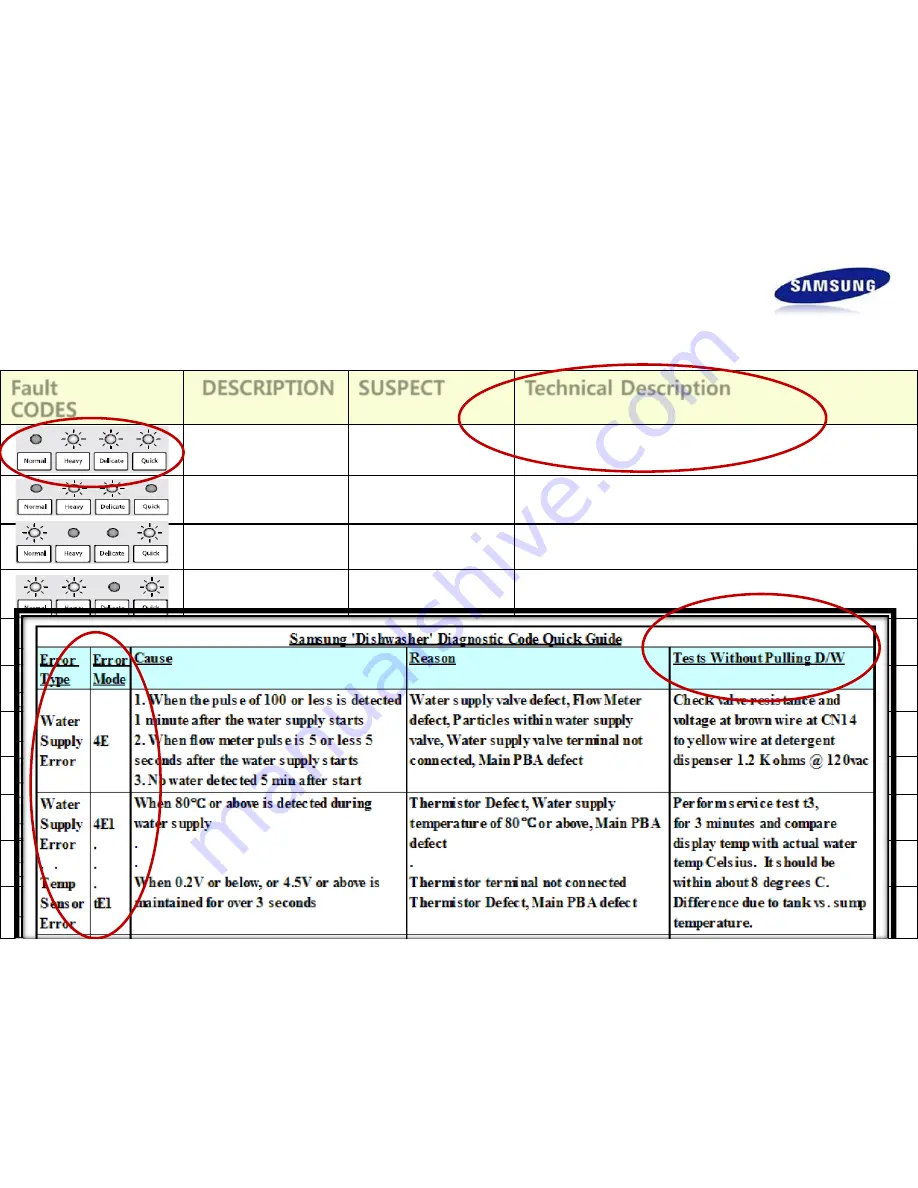

Water supply error

4E

Flow Meter

Water Valve

No Water Supply

Main PCB does recognize proper or no water flow through flow meter.

Check supply and water valve

High temperature

Water supply error

4E1

Incoming Water Temp

sensed above

176F

Faulty Thermister or Main PCB / Incoming water is over 176F

Drain error

5E

Level sensor fails to open

after 3 minutes of drain

Evaluate Drain Operation / Possible kinked drain hose / obstruction in

pump or sump assembly. If water has drained check for level sensor stuck

in closed position.

Over-level Error

OE

Water reaches top of level

sensor container

Suspect stuck water valve / Faulty flow meter or possible drain issue.

Leakage error

LE

Water Present in Base of

D/W

Inspect for leaks / if no leaks present unplug sensor if code goes away

replace leak sensor if not check harness for short or pinched wire before

replacing Main PCB

Button error

6E2

Stuck Button

When a button is pressed continuously for 30 seconds.

Check panel alignment / Main or Sub PCB failure

Door open warning

Door is open in wash or at

start

Door is not close properly.

Possible defect : Door lock switch, Main PBA

How to Diagnose the Issue using the Error codes

Fast Track

Summary of Contents for DMT300 Series

Page 4: ...Required Tools Materials...

Page 5: ...Required Tools Materials...

Page 7: ...Drain Extension Hose 3 8th compression union Dishwasher Extension kit Required Tools Materials...

Page 8: ...Fine Point extended test probes Digital Multimeter Required Tools Materials...

Page 9: ...Fast Track Required Tools Materials...

Page 10: ...Fast Tracks...

Page 11: ...Fast Track What is a Fast Track...

Page 12: ...Fast Track How to download 1 2 3...

Page 13: ...Fast Track Manual Example page Fast Track Product Changes or Notifications...

Page 14: ...Fast Track Checking Components on Main PCB...

Page 15: ...Fast Track Schematic Component Test Chart...

Page 16: ...Test Mode on the fast track Fast Track How to Enter Test mode...

Page 18: ......

Page 20: ...Troubleshooting Description 9 Test Mode 9 Disassembly of Sump Heater 9 Component Description...

Page 22: ...Test Mode How to Enter Test mode...

Page 23: ...Disassembly Storm wash Nozzle DMT Disassembly Removal of the Sump Heater...

Page 26: ...Heater Sump Ass y 30 min faster heating Heater Accessed from the bottom of the D W...

Page 28: ...Main PCB Location Main Board Location on DMR series...

Page 30: ...Rear Leg Adjustment Single Leg in rear Main Board Main Board Location on DW7933 DMT 400 800...

Page 38: ...Thermal Actuator Wax Motor What is a WAX MOTOR Air Vent Dry System Wax Motor...

Page 40: ...Sensors Overflow Low Level Left side of the D W Float arm Overflow Water Level Switch...

Page 42: ...Rear leg adjuster...

Page 43: ...Precautions Improvements...

Page 46: ...Precautions Leaking Door Leakage from the door...

Page 47: ...Improvements Quietness...

Page 48: ...Improvements Hidden Dryer Element...

Page 49: ...Improvements Food Residue...

Page 50: ...Improvements Loading Flexibility...

Page 51: ...Improvements Leakage Sensor...

Page 52: ...Improvements 3 wash Arms...

Page 53: ...Improvements Condensed Drying...