Samsung Electronics

1-1

1. Precautions

1-1 Safety Precautions

1) Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including, but not limited to, the following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1)Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

remove for servicing convenience.

(2)When reinstalling the chassis and/or other as-

sembly in the cabinet, be sure to put back in place

all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fish papers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not oper-

ate this instrument or permit it to be operated with-

out all protective devices correctly installed and

functioning.

(2) Be sure that there are no cabinet openings through

which adults or children might be able to insert

their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, excessive-

ly wide cabinet ventilation slots, and an improper-

ly fitted and/or incorrectly secured cabinet back

cover.

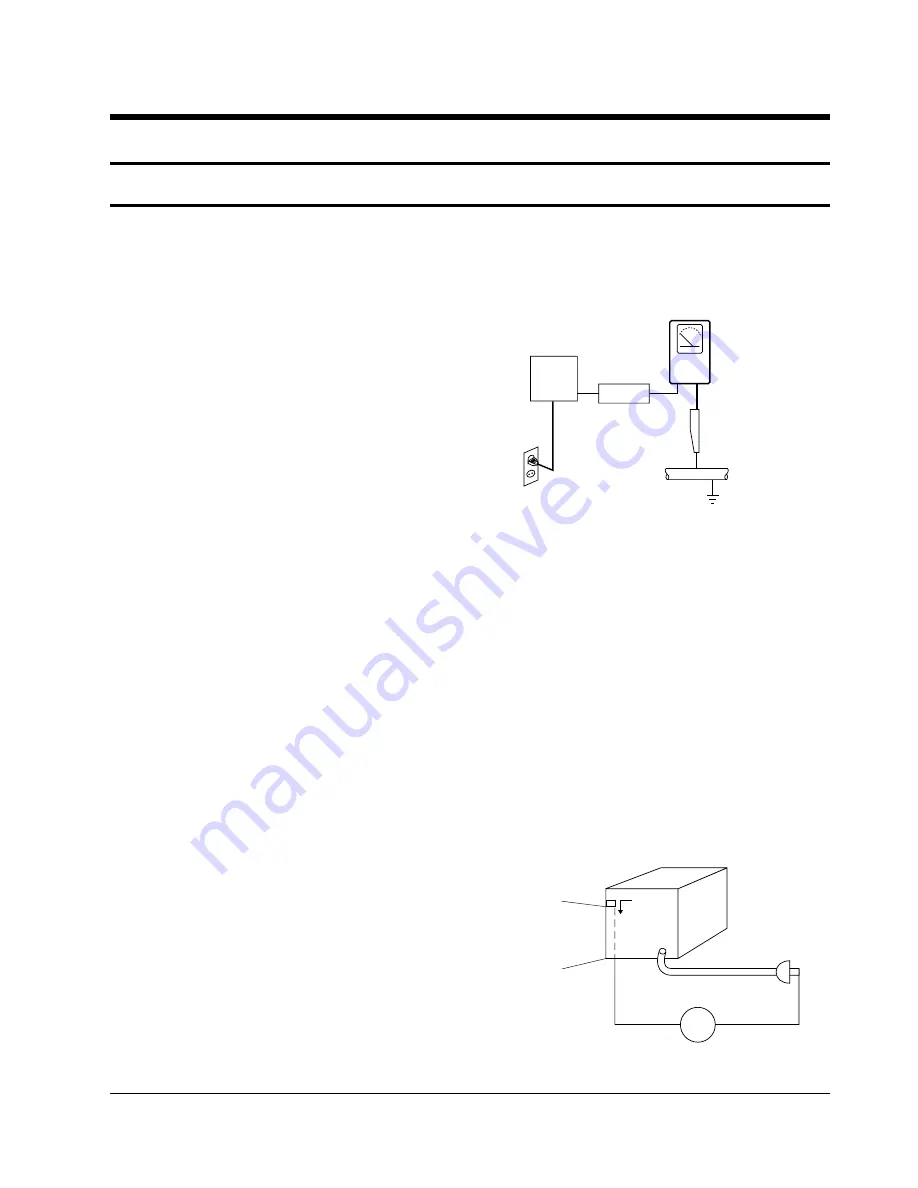

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use a isola-

tion transformer during this test.) Use a leakage

current tester or a metering system that complies

with American National Standards institute (ANSI)

C101.1 Leakage Current for Appliances and

Underwriters Laboratories (UL) 1270 (40.7). With

the instrument’s AC switch first in the ON position

and then in the OFF position, measure from a

known earth ground (metal water pipe, conduit,

etc.) to all exposed metal parts of the instrument

(antennas, handle brackets, metal cabinets, screw-

heads, metallic overlays, control shafts, etc.), espe-

cially any exposed metal parts that offer an electri-

cal return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the out-

let and repeat the test. See Fig. 1-1.

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to

the customer.

Fig. 1-1 AC Leakage Test

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug. (2) Turn on the

power switch of the instrument. (3) Measure the

resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic cabinet

parts on the instrument, such as screwheads,

antenna, control shafts, handle brackets, etc. When

an exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2

megohm. When there is no return path to the chas-

sis, the reading must be infinite. If the reading is

not within the limits specified, there is the possibil-

ity of a shock hazard, and the instrument must be

re-pared and rechecked before it is returned to the

customer. See Fig. 1-2.

Fig. 1-2 Insulation Resistance Test

DEVICE

UNDER

TEST

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

TEST ALL

EXPOSED METER

SURFACES

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2-WIRE CORD

Antenna

Terminal

Exposed

Melal Part

ohm

ohmmeter

Summary of Contents for DVD-C600

Page 23: ...Reference Information 2 16 Samsung Electronics MEMO ...

Page 49: ...4 24 Samsung Electronics Disassembly and Reaasembly MEMO ...

Page 79: ...Troubleshooting 6 10 Samsung Electronics MEMO ...

Page 85: ...Exploded Views and Parts List 7 6 Samsung Electronics MEMO ...

Page 91: ...8 6 Samsung Electronics Electrical Parts List MEMO ...

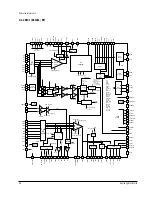

Page 95: ...PCB Diagrams 10 2 Samsung Electronics 10 1 Main COMPONENT SIDE SOLDER SIDE ...

Page 96: ...PCB Diagrams Samsung Electronics 10 3 10 2 Jack ...

Page 97: ...PCB Diagrams 10 4 Samsung Electronics 10 3 S M P S ...

Page 98: ...PCB Diagrams Samsung Electronics 10 5 10 4 Front COMPONENT SIDE SOLDER SIDE ...

Page 99: ...PCB Diagrams 10 6 Samsung Electronics 10 5 Key COMPONENT SIDE SOLDER SIDE ...

Page 100: ...PCB Diagrams Samsung Electronics 10 7 10 6 Head Phone 10 7 Deck COMPONENT SIDE SOLDER SIDE ...

Page 101: ...PCB Diagrams 10 8 Samsung Electronics 10 8 Sensor 10 9 Motor ...

Page 103: ...Wiring Diagram 11 2 Samsung Electronics MEMO ...

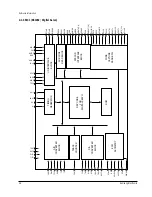

Page 105: ...Schematic Diagrams 12 2 Samsung Electronics 12 1 S M P S ...

Page 106: ...Schematic Diagrams Samsung Electronics 12 3 12 2 Main Power Supply ...

Page 107: ...Schematic Diagrams 12 4 Samsung Electronics 12 3 Main Micom ...

Page 108: ...Schematic Diagrams Samsung Electronics 12 5 12 4 Servo ...

Page 109: ...Schematic Diagrams 12 6 Samsung Electronics 12 5 Video Encoder ...

Page 110: ...Schematic Diagrams Samsung Electronics 12 7 12 6 Video CVBS Output Y Output C Output ...

Page 111: ...Schematic Diagrams 12 8 Samsung Electronics 12 7 Audio DAC ...

Page 112: ...Schematic Diagrams Samsung Electronics 12 9 12 8 Audio ...

Page 113: ...Schematic Diagrams 12 10 Samsung Electronics 12 9 RF ...

Page 114: ...Schematic Diagrams Samsung Electronics 12 11 12 10 ZiVA ...

Page 115: ...Schematic Diagrams 12 12 Samsung Electronics 12 11 DSP ...

Page 116: ...Schematic Diagrams Samsung Electronics 12 13 12 12 Front Micom VFD Display ...

Page 118: ...Schematic Diagrams Samsung Electronics 12 15 12 14 Head Phone ...

Page 119: ...Schematic Diagrams 12 16 Samsung Electronics 12 15 Key ...

Page 120: ...Schematic Diagrams Samsung Electronics 12 17 12 16 Deck ...

Page 121: ...Schematic Diagrams 12 18 Samsung Electronics 12 17 Deck Control ...

Page 122: ...Schematic Diagrams Samsung Electronics 12 19 12 18 Remote Control ...

Page 123: ...Schematic Diagrams 12 20 Samsung Electronics MEMO ...