9-8

Samsung Electronics

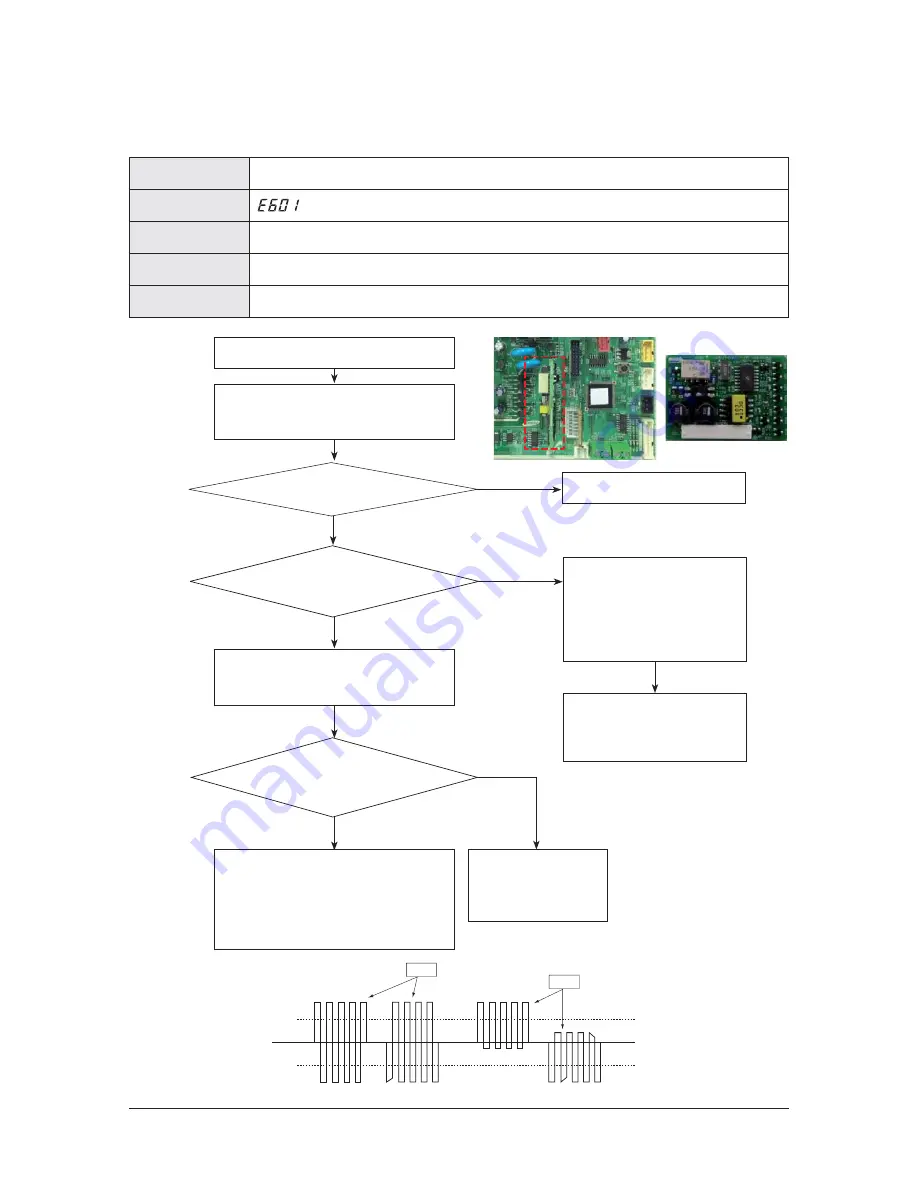

Error Mode

Communication error

Display

Check Method

Communication between wired remote control and ventilator continues to fail for longer than two minutes.

Cause

OPTION setup, PCB check or replacement

Sensor SPEC.

Communication F3, F4

9-4-6 Wired Remote Control Communication Error

+0.7V

-0.7V

G

oo

d

B

ad

Check number of ventilators

connected at the time of tracking.

Check the first SEGMENT of PCB display

of ventilators connected with wired

remote control, in order to find out

“U” flickers.

Check communication line and

connector of ventilator of

which “U” does not flicker.

Then replace PCB.

Yes

아니오

Number of ventilators connected

at the time of tracking is indicated?

Is voltage of the 2 lines square wave of over

DC±0.7V as seen in the picture below?

No

E601 code appears when unit operation

starts or while it is in operation.

Start retracking with pressing both Wind Strength

Control Button and Operation Selection Button of

Wired Remote Control simultaneously for 5 seconds.

Eliminate communication line between

Wired Cemote Control and Ventilator. Measure

2 lines of Wired Remote Control with SCOPE.

Reconnect communication line between wired

remote control and ventilator. Eliminate all

communication connectors on PCB and connect

them again one by one. Find out the ventilator

interrupting communication and check its lines.

Then, replace PCB.

Yes

Check wired remote control

PCB communication line and

connector and replace PCB.

No

SUB PBA Reassembly.

No

Check the correct connection of SUB PBA.

Yes