49

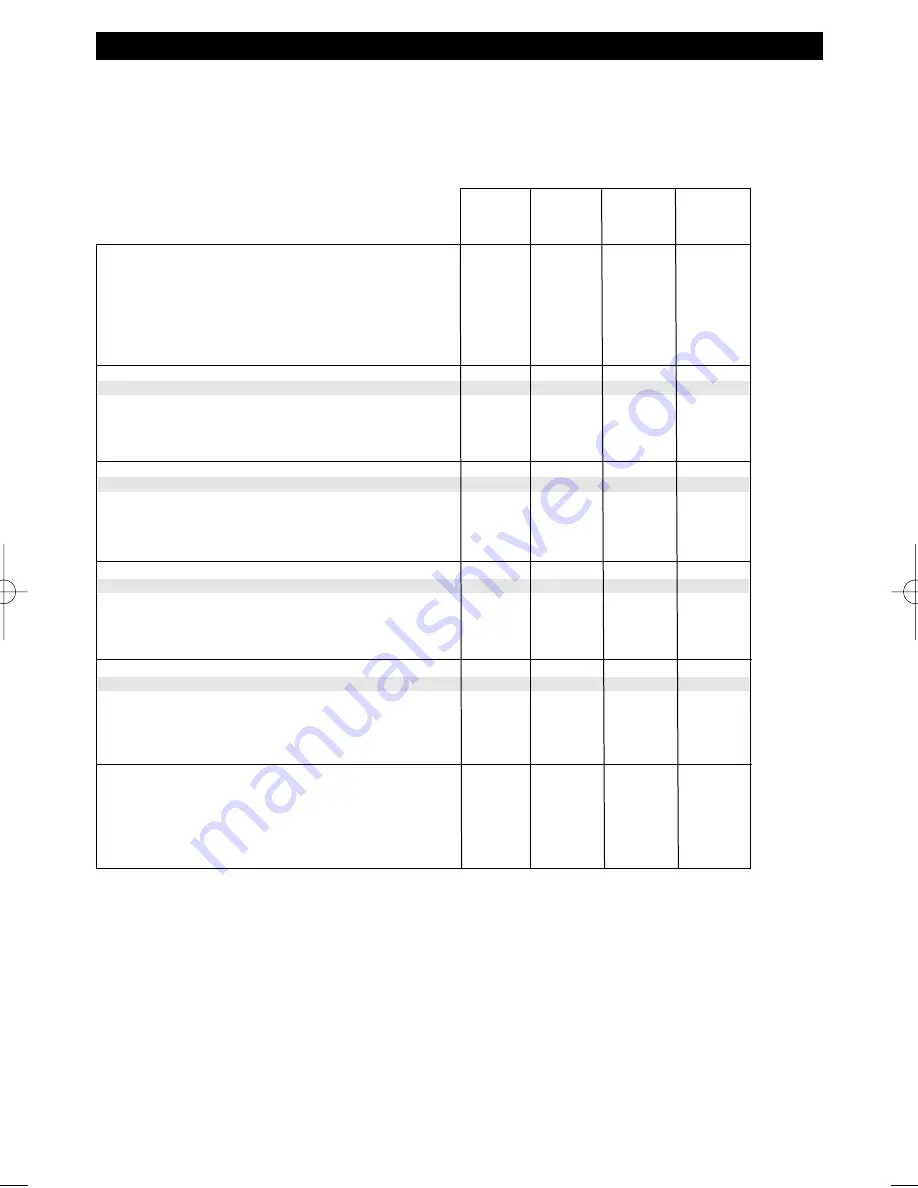

•Gas Properties

1

1 // INSTALLING YOUR APPLIANCE

IIT

T

G

GB

B

IIT

T

G

GB

B

IIT

T

S

SE

E

G

GB

B

S

SE

E

A

Ap

pp

plliic

ca

an

nc

ce

e iin

ntte

en

nd

de

ed

d tto

o b

be

e iin

ns

stta

alllle

ed

d iin

n::

B

Bu

utta

an

ne

e

P

Prro

op

pa

an

ne

e

N

Na

attu

urra

all

B

Bu

utta

an

ne

e

g

ga

as

s

G

GB

B -- IIT

T ................................................c

ca

att:: IIII2

2H

H3

3+

+

G30

G31

G20

G30

S

SE

E ..............................................................c

ca

att:: IIII2

2H

H3

3 B

B//P

P

28-30 mbar

37 mbar

20 mbar

30 mbar

Hourly rate below:

At 15° C under 1013 mbar

H

H

IIG

GH

H

--

S

SP

PE

EE

ED

D B

BU

UR

RN

NE

ER

R

Marking engraved on injector

7

78

8

7

78

8

1

12

21

1

7

78

8

Nominal heat release rate

(kW)

2,25

2,25

2,25

2,25

Reduced heat release rate

(kW)

0,850

0,850

0,850

Hourly rate

(g/h)

164

161

164

Hourly rate

(l/h)

214

D

D

O

OU

UB

BL

LE

E C

CR

RO

OW

WN

N B

BU

UR

RN

NE

ER

R

Marking engraved on injector

9

95

5

9

95

5

1

14

47

7

9

95

5

Nominal heat release rate

(kW)

3,50

3,50

3,80

3,50

Reduced heat release rate (with safety)

(kW)

1,450

1,400

1,450

Hourly rate

(g/h)

254

250

254

Hourly rate

(l/h)

362

S

S

E

EM

MII

--

F

FA

AS

ST

T B

BU

UR

RN

NE

ER

R

Marking engraved on inector

6

62

2

6

62

2

9

94

4

6

62

2

Nominal heat release rate

(kW)

1,45

1,45

1,50

1,45

Reduced heat release rate (with safety)

(kW)

0,700

0,650

0,700

Hourly rate

(g/h)

105

104

105

Hourly rate

(l/h

143

A

AU

UX

XIIL

LIIA

AR

RY

Y B

BU

UR

RN

NE

ER

R

Marking engraved on injector

5

50

0

5

50

0

6

63

3

5

50

0

Nominal heat release rate

(kW)

0,900

0,900

0,850

0,900

Reduced heat release rate

(kW)

0,350

0,300

0,350

Hourly rate

(g/h)

65

64

65

Hourly rate

(l/h)

81

H

H

O

OB

B

,, 6

60

0 c

cm

m,,

F

FO

OU

UR

R

--

B

BU

UR

RN

NE

ER

R G

GA

AS

S M

MO

OD

DE

EL

L W

WIIT

TH

H D

DO

OU

UB

BL

LE

E C

CR

RO

OW

WN

N B

BU

UR

RN

NE

ER

R

Total heat release rate

(kW)

8,10

8,10

8,40

8,10

Maximum flow rate

(g/h

588

579

588

(l/h)

800

99640621_A_ML.qxp 06/09/2006 09:47 Page 49