Printing on special media

64

2. Media and Tray

8

Transparency

To avoid damaging the machine, use only transparencies designed for use in

laser printers.

•

In case of color printing using transparencies, the picture quality would

be lower than mono printing when the printouts are used on the

overhead projector.

•

Transparencies used in the machine must be able to withstand the

machine’s fusing temperature.

•

Place them on a flat surface after removing them from the machine.

•

Do not leave unused transparencies in the paper tray for long periods of

time. Dust and dirt may accumulate on them, resulting in spotty printing.

•

To avoid smudging caused by fingerprints, handle them carefully.

•

To avoid fading, do not expose printed transparencies to prolonged

sunlight.

•

Ensure that transparencies are not wrinkled, curled, or have any torn edges.

•

Do not use transparencies that separates from the backing sheet.

•

To prevent transparencies from sticking to each other, do not let the printed

sheets stack up as they are begin printed out.

•

Recommended media: Transparency for a color laser printer by Xerox, such

as 3R 91331(A4), 3R 2780(Letter).

•

Prints made on transparency film with this printer are not compatible with

overhead projectors and may appear as a black and white image if

projected.

9

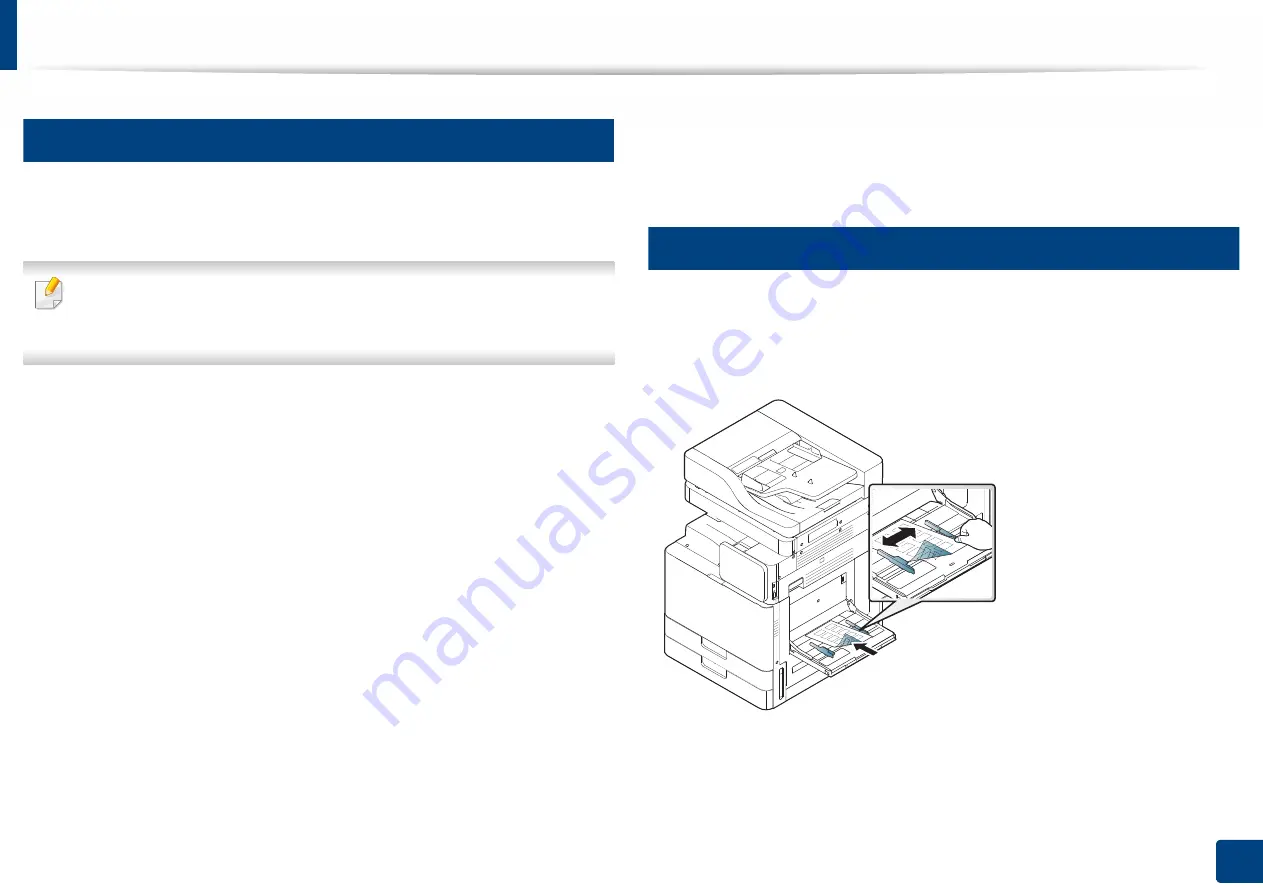

Labels

Load the paper with the side to be printed on facing down.

To avoid damaging the machine, use only labels designed for use in laser

machines.

•

When selecting labels, consider the following factors:

-

Adhesives:

The adhesive material should be stable at your machine’s

fusing temperature of about 170°C (338 °F) for 0.1 second.