4. Troubleshooting

4.5.5.3. Scanner Diagnostics

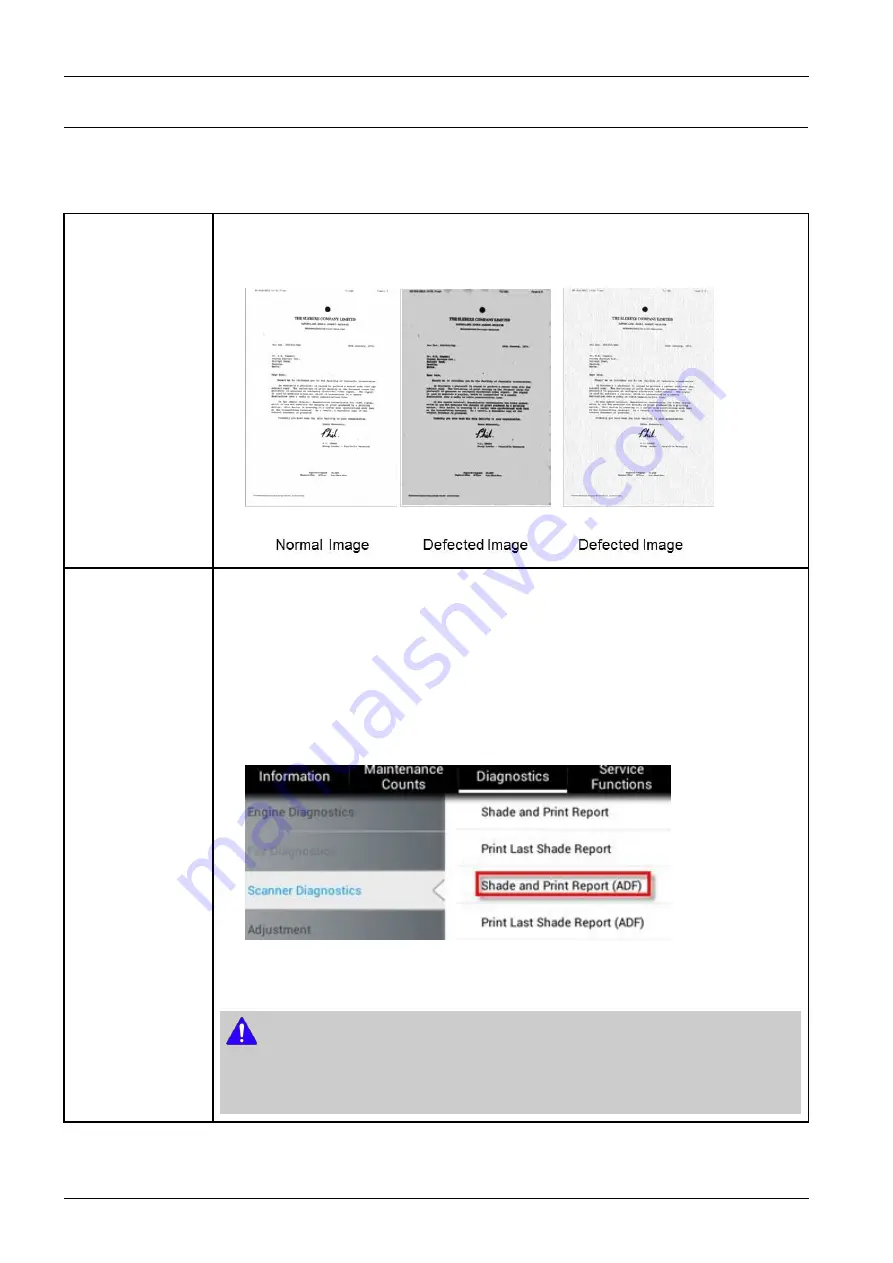

Shading Test

•

Diagnostics > Scanner Diagnostics > Shading Test

Purpose

•

To check quality of scanned images, especially defect in optical devices, including lens,

mirror, lamp, and etc, are suspected.

•

To check quality problem as shown below

Operation Procedure

[For Platen Unit]

Press "Shade and Print report“ to see if the current shading value is correct.

Mono, red, green, blue gray shading values will be shown on the printed report.

When the previous shading value is needed, press “Print Last Shade Report”.

[For ADF(DSDF) Unit]

1) Load the shading sheet on the DSDF tray.

2) Enter SVC mdoe. Select the following menu.

(

Diagnostics > Scanner Diagnostics > Shading Test > Shade and Print Report(ADF)

)

(When the previous shading value is needed, press “Print Last Shade Report(ADF)”. )

3) Check if RESULTS on the sheet is OK.

NOTE

•

When executing DSDF shading, use only shading sheet(

JC63-05055A

).

•

Shading Test for ADF Unit must be carried out, after replacing the DSDF unit or main board.

4-42

Copyright© 1995-2017 SAMSUNG. All rights reserved.