26 English

Ins

tallation ins

truc

tions

Installation instructions

To adjust flame low setting

Identify which burner is exhibiting too high or too low of simmer rate via manifold

panel graphics.

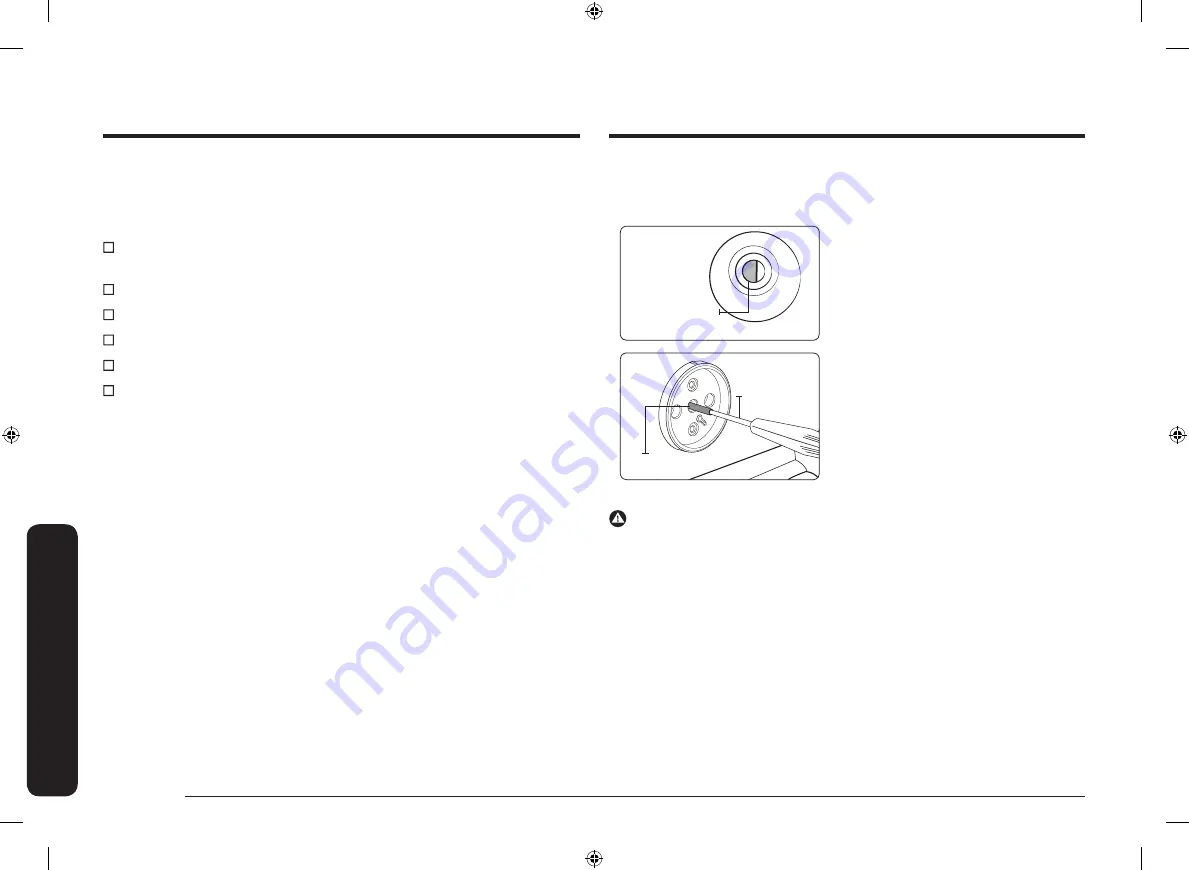

Simmer Set

Screw

1.

Rotate a knob to

LO

position and

remove the knob from the valve stem

while the flame is lit.

Small

Screwdriver

Valve Stem

2.

Carefully push the screw driver into

the stem of the valve, until it hits

the simmer set screw. Make sure the

screwdriver flathead is seated into the

set screw groove.

3.

Rotate valve set screw clockwise to

decrease

LO

setting flame output, or

rotate set screw counter clockwise to

increase

LO

setting flame output.

WARNING

1.

Do not completely remove the valve set screw from the valve stem. The valve

set screw is an integral part of the gas valve assembly. Removing the valve

set screw will cause gas to leak.

2.

After adjusting the valve set screw, inspect the assembly for gas leaks.

Step 14. Final installation checklist

You have just completed installing your range. Make sure all controls are in the off

position and the flow of ventilation air to the range is unobstructed. The following

is a checklist to confirm your range is safely installed and ready for operation.

Gas line has been properly connected to the range. The gas has been turned

on. All connections have been checked for leaks.

Range is plugged into the properly grounded electrical receptacle.

Approved anti-tip bracket is properly installed and engaged with the range.

Range is leveled and is firmly sitting on a solid, level floor.

Gas surface burners have been properly assembled.

All burners have been tested for proper operation.

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 26

2020-03-27 11:10:10