Circuit Description

13-6

Samsung Electronics

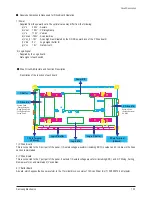

2. X, Y Control Block

■

Drive Circuit Definition

The Drive Circuit is a circuit that generates a waveform (high-voltage pulse) for the X and Y electrode group of the panel's external

port so as to control the panel. The high-voltage switching pulse is generated through the combination of the IC HYBRID (Drive

block + IGBT) and FET.

■

Drive Circuit Mechanism

A picture is displayed on the PDP by applying voltage to the X, Y and ADDRESS electrodes of each pixel according to the appro-

priate condition. The drive waveform applied to 42HD V4 is of the ISSS (ISSS: Interweaving Scan and Selective Sustain with Scan

IC) type and has IDS (InDependent Sustain) in the Scan section unlike the existing ADS. Discharges within a PDP pixel can be

classified into 3 types:

①

Address Discharge: To form a wall voltage within the pixel by giving information (applying DATA voltage) to the pixel to be lit.

②

Sustain Discharge: Sustain Discharge is a display section that voluntarily maintains the discharge of the pixels whose wall

voltage has been formed by the Address Discharge. (Optical output for displaying a picture is generated).

③

Erase Discharge: To selectively perform Address Discharge for each pixel, all pixels on the panel should be in the same status

(the wall electric charge status and space electric charge status must be the same). Therefore, the Erase

Discharge section is an important component for guaranteeing the drive margin, and is implemented by

various methods such as applying a log waveform. However, the current 42HD V4 has adopted a wall voltage

control through an RA (Repeated Auto-quenching) reset that separates the discharge area and performs

switching to perform an efficient erase operation, while the gradient was the same in the RAMP section in the

existing approach.

1) Address Discharge

A discharge that is caused by the difference between the plus electric potential (Va apply voltage of 65~70V + Positive Wall

Charge) of the electrode and the negative electric potential (Applied GND Level + Negative Wall Charge) of the Y electrode. The

Address discharge forms a wall voltage within the pixel to display color (to be discharged) before the Sustain Discharge period.

That is, the pixel whose wall charge has been formed by the Address Discharge forms a Sustain Discharge vis the following

Sustain pulse.

2) Sustain Discharge

A Sustain Discharge is a Self-Sustaining Discharge formed by the accumulation of the electric potential of the Sustain pulse (gen-

erally 200 ~ 210 Volt) alternating over the X and Y electrodes during the sustain period, and the wall charge depending on whether

the pixel has previously been discharged or not. That is, it is controlled by the memory characteristics, one of the basic characteris-

tics of the AC PDP (in that the past operating conditions determine the current status). That is, if a wall voltage exists on the pixel

(if the pixel is on), a discharge is formed again because the applied voltage, which is the sum of the following applied Sustain volt-

age and the wall voltage, is higher than the discharge threshold voltage. If no wall voltage exists on the pixel (if the pixel is off), a

discharge will not occur because the Sustain voltage is not higher than the discharge threshold voltage. The Sustain Discharge

period is the period for generating actual optical output so as to display a picture on the PDP screen.

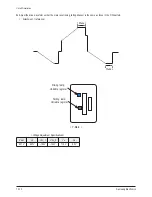

3) Erase Discharge

The purpose of a Reset (Erase) Discharge is to create uniformity of the wall voltage within all panel pixels. It evens the wall volt-

ages regardless of the Sustain Discharge in the previous stage. The Erase Discharge has to remove the wall voltage introduced by

the Sustain Discharge by supplying ions or electrons by a discharge. When the wall voltage is removed through a discharge, the

time when the reverse polarity is applied to the wall voltage (fine width erasing) is to be limited or ions or electrons are to be sup-

plied by a weak discharge (low voltage erasing) so as to prevent a wall charge in reverse polarity.

There are 2 known weak discharge (low-voltage) erase methods. 1) A log waveform adopted by F company and 2) a weak erase

discharge via a ramp waveform adopted by Matsushita and other companies. Both methods control the externally applied voltage

by the difference of the wall voltage of the pixel by applying the rising gradient of the erasing waveform slowly, because the dis-

charge begins when the sum of the existing remaining wall voltage and the rising waveform voltage exceeds the drive threshold

voltage. In addition, a weak discharge is introduced, because the applied voltage is low.

Summary of Contents for PL42E7SX/RCL

Page 18: ...11 8 Samsung Electronics MEMO ...

Page 43: ...Circuit Description Samsung Electronics 13 15 Scan_l Even_Scan Y Sustain ...

Page 44: ...Circuit Description 13 16 Samsung Electronics Attachment 2 X Output Waveform X Sustain ...

Page 52: ...9 8 Samsung Electronics MEMO ...

Page 81: ...3 18 Samsung Electronics MEMO ...

Page 96: ...6 14 Samsung Electronics MEMO ...

Page 98: ...Samsung Electronics 5 2 MEMO ...