2. Product Specification and description

2.2.6. Engine Firmware Control Algorithm

2.2.6.1. Feeding

If feeding from a cassette, the drive of the pickup roller is controlled by controlling the solenoid. The on/off of the

solenoid is controlled by controlling the general output port or the external output port. Provided below are the jam

conditions for the device:

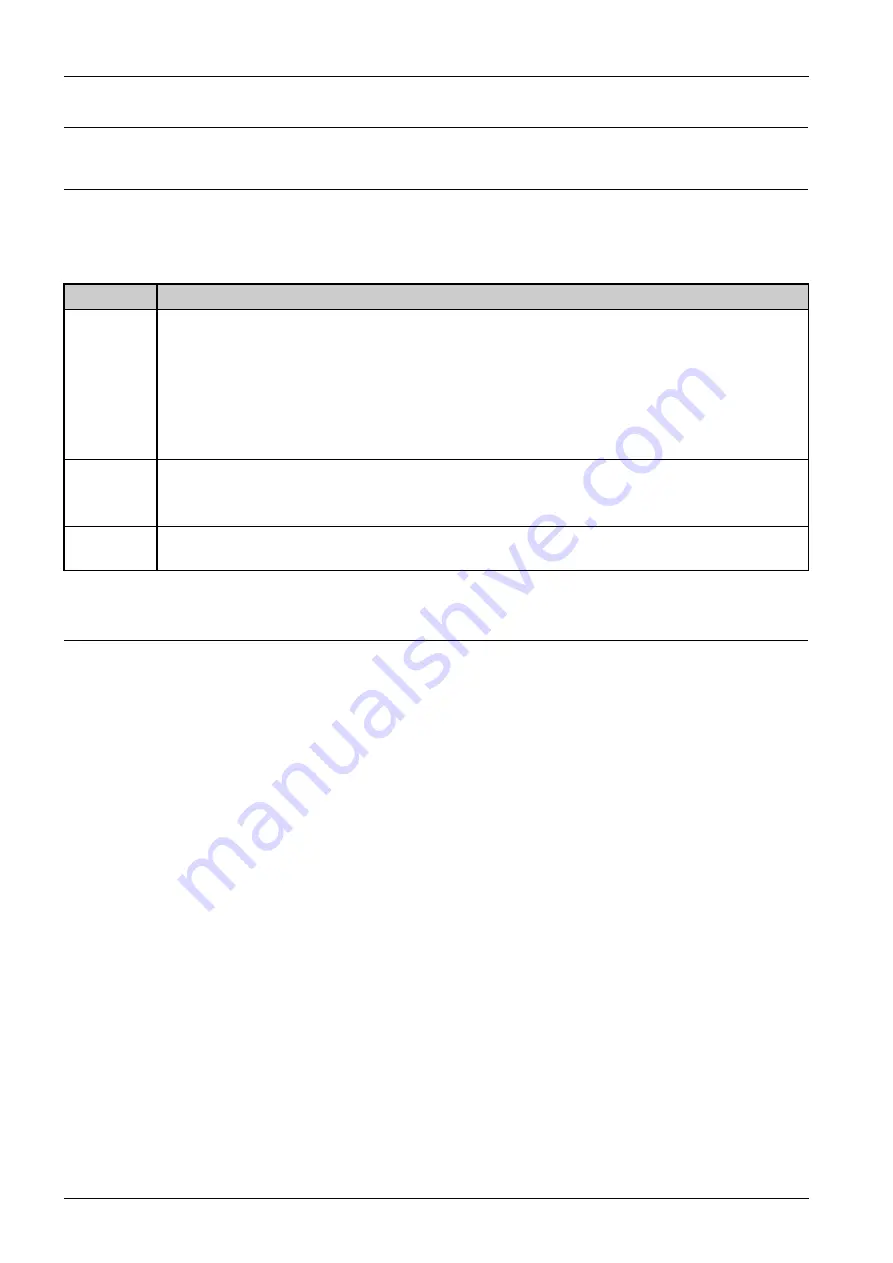

Item

Description

Paper jam in

tray1

•

After paper pick up initialization, the paper is not fed.

•

After picking up the paper the lead edge does not reach to the feed sensor within a predetermined

period of time, due roller slippage, etc.

•

After picking up the paper from the cassette, if the feed sensor is not detected, a re-pick up

initialization occurs. After re-picking up, if the feed sensor is still not on after a predetermined

amount of time, jam occurs.

•

Even though the paper reaches to the feed sensor, the feed sensor doesn’t be ON.

Paper jam

inside of

machine

•

Even though the paper reaches to the feed sensor, the feed sensor doesn’t not change state.

•

After the tail edge of the paper passes the feed sensor, the lead edge of paper is not detected by the exit

sensor within a predetermined period of time.

Paper jam in

exit area

The trail edge of the paper does not clear the exit sensor within a predetermined period of time.

2.2.6.2. Transfer

The charging voltage, developing voltage and the transfer voltage are controlled by PWM (Pulse Width Modulation). Each

output voltage is changeable due to the PWM duty. The transfer voltage admitted when the paper passes the transfer roller

is decided by environment conditions. The resistance value of the transfer roller is changed when the Temperature and

Humidity Sensor in the device senses a change in the environment. The current to the Transfer Roller is changed using an

AD converter on the HVPS. The voltage value for impressing to the transfer roller is decided by the changed value.

2-29

Copyright© 1995-2017 SAMSUNG. All rights reserved.