1-1. Safety precautions

1-1. Safety precautions

Only qualified service technicians who are thoroughly familiar with the refrigerating cycle and the

required safety checks should perform service operations in accordance with specified guidelines.

1 -1-1. Prior to servicing, be sure to disconnect the product from its electrical power source by removing the

products eletrical plug from the wall receptacle to preclude the possibility of resultant presonal injury

and / or property damage.

1-1-2. Never attempt to modify or bypass circuit connections in ways not recommended by the manufacturer.

1-1-3. Do not use any extension or double adaptors.

1-1-4. For person safety, this appliance must be properly grounded.

This refrigerator should not be grounded with a telephone line, gas pipe etc.

1 -2-1. In case of article No.1 and starting capacitor ( itself only ) do not supply power in order to check for

eletrical charge and discharge for more than two minutes. When power is supplied for more than two

minutes, the insulation inside the capacitor may be broken. When it is impossible to finish the test

within two minutes, wait for about 30 minutes, and then check again.

1-2-2. When replacing the relay connected to the compressor terminal pin, be sure to pull it off straight and

push it on straight, Swaying of the relay side-to-side or up and down, may cause damage to the

compressor terminal pin and / or the relay.

1-2-3. Wait more than 5 minutes to re-start the refrigerator after you stop it once.

If you plug in the refrigerator immediately after you pull the plug, you may not be able to start it again.

1-2. Servicing precautions

1-2. Servicing precautions

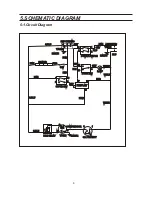

: This is safety-related information on the A/ C power circuits and parts used in the refrigerator.

: This is the information required for repairing the refrigerator.

1

1.PRECAUTION

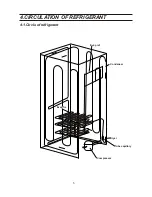

Summary of Contents for RL-28FBSI

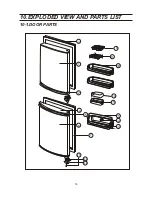

Page 16: ...10 2 PARTS LIST DOOR 15 No Part number Description Q ty Spec Remark ...

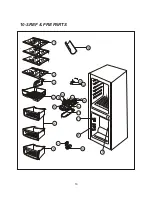

Page 17: ...10 3 REF FRE PARTS 16 1 2 3 4 5 21 20 16 15 14 17 18 19 8 11 12 6 7 13 10 9 ...

Page 18: ...10 4 PARTS LIST REF FRE 17 No Part number Description Q ty Spec Remark ...

Page 20: ...10 6 PARTS LIST CABINENT 19 No Part number Description Q ty Spec Remark ...