Fast Track Troubleshooting

IMPORTANT SAFETY NOTICE

–

“For Technicians Only”

This service data sheet is

intended for use by persons having electrical, electronic, and mechanical experience

and knowledge at a level generally considered acceptable in the appliance repair trade.

Any attempt to repair a major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible, nor assume any liability for

injury or damage of any kind arising from the use of this data sheet.

Models Covered:

RM255****

4 Door Refrigeration

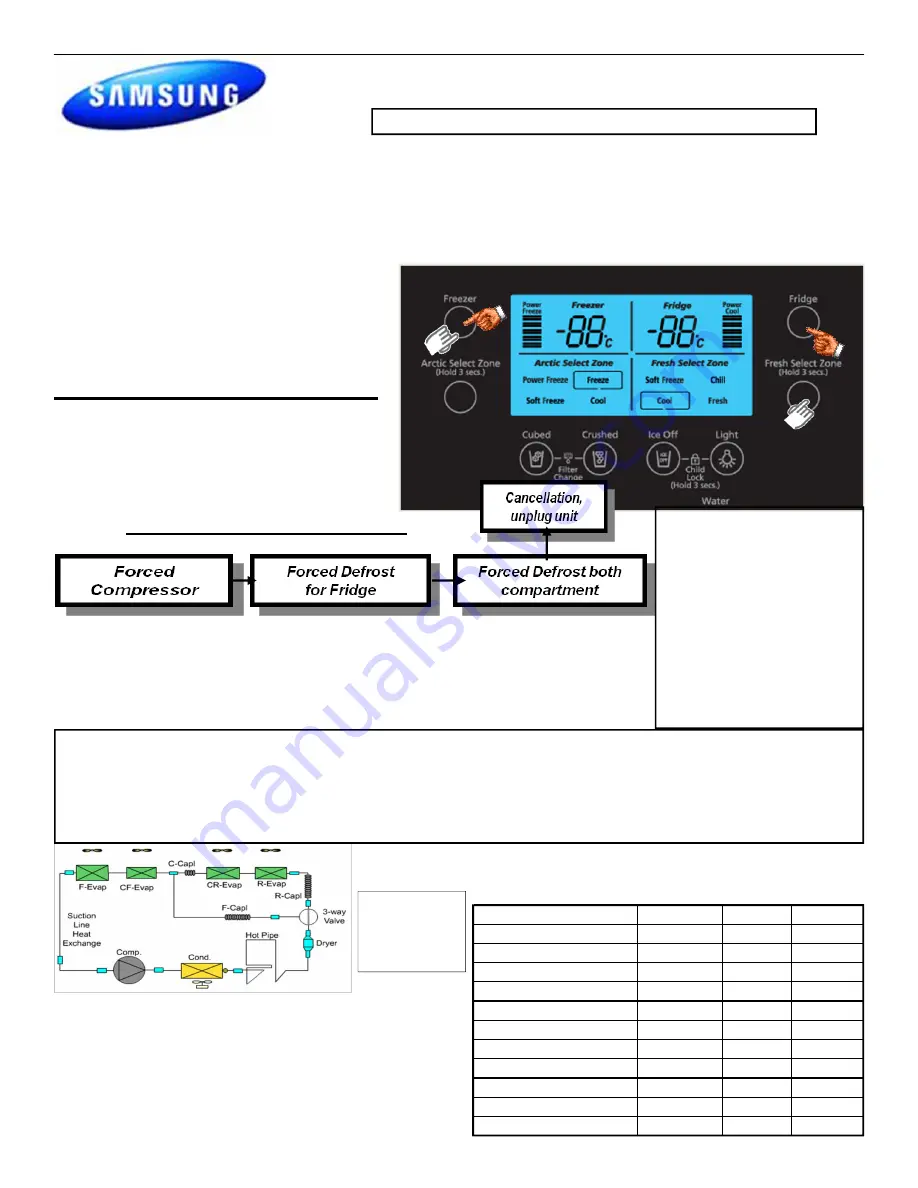

Wait 5 seconds between button pushes

Self Diagnosis: Press both buttons (Freezer–

Fridge)

simultaneously

(No sound when both

buttons are pressed at the same time) ’til the

display quits blinking and beeps, 8-12 sec-

onds, then release and read Fault Codes.

This will also cancel the Fault Mode created

by self-diagnosis at power up.

Forced Mode: Press both buttons (Freezer–

Fresh Select Zone)

simultaneously

(No

sound when both buttons are pressed at

the same time) ‘til it beeps and goes blank,

8-12 seconds

Publication # tsRM255 Creation Date 08/24//2009

Component Value Chart

Component

Resistance Wattage Voltage

Freezer Defrost Heater

72

Ω

200

120vac

Fridge Defrost Heater

180

Ω

80

120vac

CF Defrost Heater

144

Ω

100

120vac

CR Defrost Heater

180

Ω

80

120vac

F Drain Tube/Heater

2880

Ω

5

120vac

R Drain Tube/Heater

2880

Ω

5

120vac

Dispenser Heater

2880

Ω

5

120vac

Water Tank Heater

29

Ω

5

12vdc

Fill Tube Heater

29

Ω

5

12vdc

Sensors

2.5k

Ω

-89k

Ω

N/A

1~4.5vdc

Fans

N/A

N/A

7~12vdc

1. Compressor

→

Sub-condenser

→

Hot Pipe

→

Back Clus-

ter Pipe

→

Dryer

→

R Capillary Tube

→

Refrigerator Evapo-

rator /CR Evaporator

→

Connected Capillary

→

Freezer

Evaporator/CF Evaporator

→

Suction Pipe

→

Compressor

2. Compressor

→

Sub-condenser

→

Hot Pipe

→

Back Clus-

ter Pipe

→

Dryer

→

F Capillary Tube

→

Freezer Evaporator/

CF Evaporator

→

Suction Pipe

→

Compressor

Press Freezer button one

time at the Test Mode to

Force Compressor Run,

measure fan and com-

pressor voltages at PCB

Press Freezer button a

second time to Force

Defrost of Fridge, meas-

ure defrost voltage at

main PCB

Press Freezer button a

third time to Force Defrost

for Fridge & Freezer,

measure defrost voltages

at main PCB

Refrigerant

Charge

R134a

7.76 oz

Sales Mode, No Compres-

sor Operation: Press

Freezer & Arctic Select

Zone buttons simultane-

ously for 3 sec ( you will

hear a “Ding Dong”) to re-

move or put into Sales

Mode. When in the Sales

Mode the Display will show

"OF" "OF"

Removing power will not

cancel this mode.

Sealed System

FREEZER TEMPERATURE CONTROL BY THE ICE MAKER

Interior Temperature of the freezer will be set to -14 degrees Fahrenheit until the ice bucket is full. When the ice

bucket is full, the freezer will maintain original set temperature. Also, whenever the ice is used, the freezer will

again set to -14 degrees Fahrenheit. Selecting "Ice Off” will allow the freezer to be controlled by the set tem-

perature. If water is not hooked up, the freezer will always be at –14 unless “Ice Off” is selected.

1