5-10

Disassembly and Reassembly

Samsung Electronics

Service Manual

5.7 Exit Roller

1. Before you remove the Exit Roller you should remove:

- Rear Cover (see page 5-2)

- Side Covers (see page 5-3)

- Scanner Ass’y (see page 5-4)

- Middle Cover (see page 5-6)

2. Remove the white Exit Gear, and release a bearing

clip at one end then remove the shaft and rollers as

shown below.

Exit Gear

Bearing

Exit Roller

1

2

5.8 LSU

1. Before you remove the LSU you should remove:

- Rear Cover (see page 5-2)

- Side Covers (see page 5-3)

- Scanner Ass’y (see page 5-4)

- Middle Cover (see page 5-6)

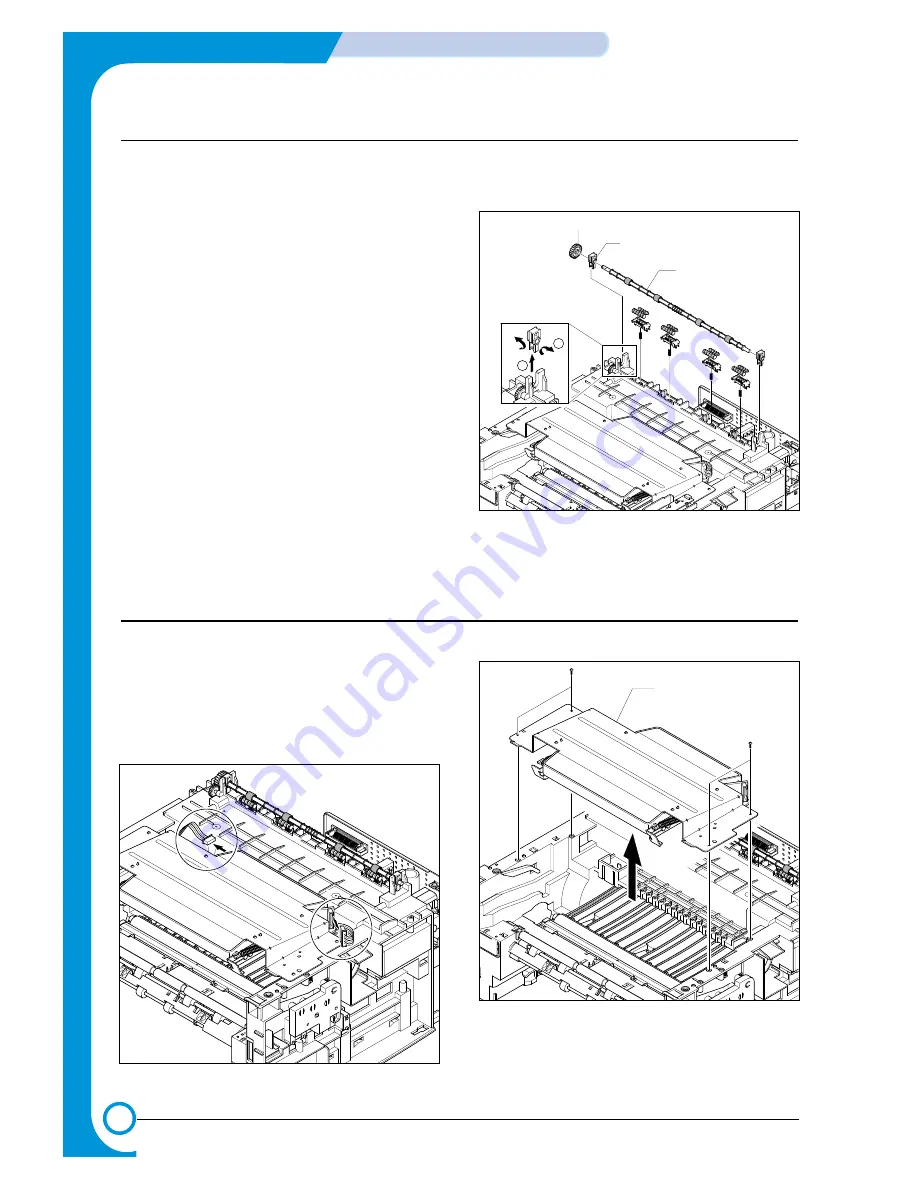

2. Unplug 2 connector from the LSU.

3. Unplug 4 screws and take the LSU out.

LSU

Summary of Contents for scx-4100 series

Page 13: ...2 6 Reference Information Samsung Electronics Service Manual 2 4 2 A4 2 Pattern ...

Page 14: ...2 7 Samsung Electronics Reference Information Service Manual 2 4 3 A4 IDC 5 Patten ...

Page 15: ...2 8 Reference Information Samsung Electronics Service Manual MEMO ...

Page 21: ...3 6 Specifications Samsung Electronics Service Manual MEMO ...

Page 23: ...4 2 Summary of Product Samsung Electronics Service Manual 4 1 2 Rear View ...

Page 24: ...4 3 Samsung Electronics Summary of product Service Manual 4 1 3 Control Panel ...

Page 25: ...4 4 Summary of Product Samsung Electronics Service Manual 4 2 System Layout SCAN PART ...

Page 39: ...4 18 Summary of Product Samsung Electronics Service Manual MEMO ...

Page 57: ...5 18 Disassembly and Reassembly Samsung Electronics Service Manual MEMO ...

Page 93: ...7 28 Troubleshooting Samsung Electronics Service Manual MEMO ...

Page 110: ...9 9 9 1 Samsung Electronics Block Diagram Service Manual 9 Block Diagram ...