Precautions

Service Manual

5-1

Samsung Electronics

5

5

5. Disassembly and Reassembly

5.1 General Precautions on Disassembly

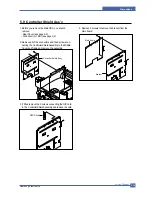

When you disassemble and reassemble compo-

nents, you must use extreme caution. The close

proximity of cables to moving parts makes proper

routing a must.

If components are removed, any cables disturbed

by the procedure must be restored as close as

possible to their original positions. Before remov-

ing any component from the machine, note the

cable routing that will be affected.

Whenever servicing the machine, you

must perform as follows:

1. Check to verify that documents are not stored

in memory.

2. Be sure to remove the toner cartridge before

you disassemble any parts.

3. Unplug the power cord.

4. Use a flat and clean surface.

5. Replace only with authorized components.

6. Do not excessive force on components made of

plastic, they may break.

7. Make sure all components are in their proper

position.

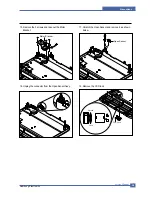

Releasing Plastic Latches

Many of the parts are held in place with plastic

latches. The latches break easily; release them

carefully.

To remove such parts, press the hook end of the

latch away from the part to which it is latched.

Summary of Contents for SCX-4720F

Page 10: ...Service Manual Reference Information 2 4 Samsung Electronics 2 3 2 A4 2 Pattern...

Page 11: ...Reference Information Samsung Electronics Service Manual 2 5 2 3 3 A4 IDC 5 Patten...

Page 14: ...Service Manual Reference Information 2 8 Samsung Electronics MEMO...

Page 24: ...Service Manual Specifications 3 10 Samsung Electronics MEMO...

Page 27: ...Summary of Product Service Manual 4 3 Samsung Electronics 4 1 3 Control Panel SCX 4720F...

Page 28: ...Service Manual Summary of Product 4 4 Samsung Electronics...

Page 51: ...Summary of Product Service Manual 4 27 Samsung Electronics MEMO...

Page 163: ...Service Manual Exploded View Parts List 8 28 Samsung Electronics MEMO...