2. Product Description

SAMSUNG ELECTRONICS

Service Manual

2-39

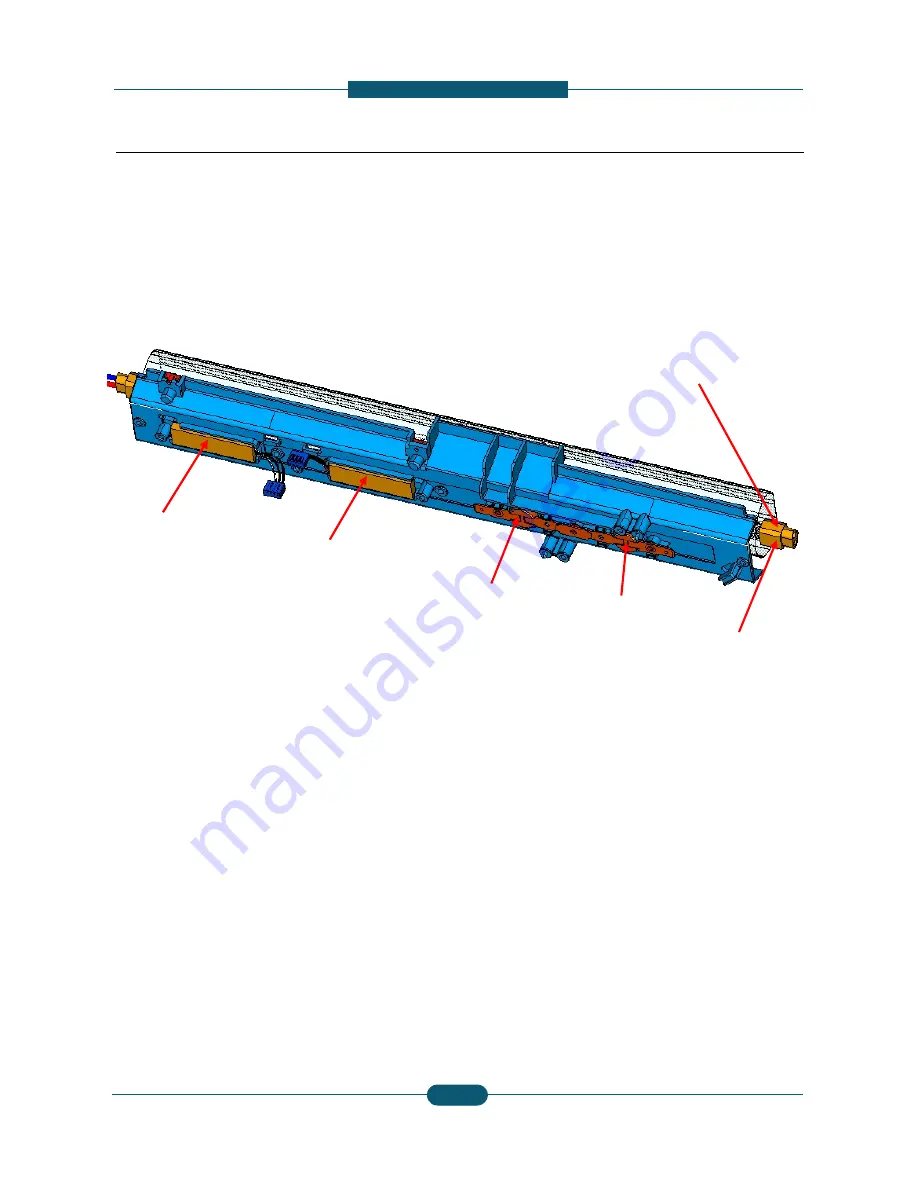

2.6.4 Temperature control

When the main switch turns on, the CPU turns on the fusing lamp. The lamp stays on until the NC sensors

detect the standby temperature. Then the CPU raises the temperature to the printing temperature.

Overheat Protection

The CPU cuts power to the fusing lamp in the following cases:

• The fuser belt temperature detected by the NC sensors becomes higher than 198

℃

.

The following components are used if thermistor overheat protection fails.

• Two thermostats for the fuser belt get into line with the common ground line of the fusing lamp.

• If one of the thermostat temperatures becomes higher than 170

°

C, it opens and cuts power to the fusing

lamp. If the other thermostat temperature becomes higher than 170

°

C, it also opens and cuts power to the

fusing lamp.

Lamp 1(700W) : Center heating

Lamp 2(600W) :

Side heating

NC Sensor1

NC Sensor2

Thermostat 1

Thermostat 2

Summary of Contents for SCX-82x0 series

Page 13: ...10 2 Abbreviations 10 4 ...

Page 112: ...2 Product Description SAMSUNG ELECTRONICS Service Manual 2 94 ...

Page 379: ...8 System 8 2 Engine 2 8 2 Engine 2 Service Manual 8 Diagram SAMSUNG ELECTRONICS 2 ...

Page 380: ...8 System 8 3 Engine 3 8 3 Engine 3 Service Manual 8 Diagram SAMSUNG ELECTRONICS 3 ...

Page 381: ...8 System 8 4 Scan DADF 8 4 Scan DADF Service Manual 8 Diagram SAMSUNG ELECTRONICS 4 ...

Page 382: ...8 System 8 5 Heater Fuse 8 5 Heater Fuse Service Manual 8 Diagram SAMSUNG ELECTRONICS 5 ...