Disassembly and Reassembly

3-16

Samsung Electronics

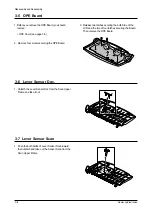

3-28 Thermostat

1. Remove one screw and remove the Cover

Thermostat from the Fuser Ass’y.

2. Remove two screws and take out Thermostat from

the Fuser Ass’y.

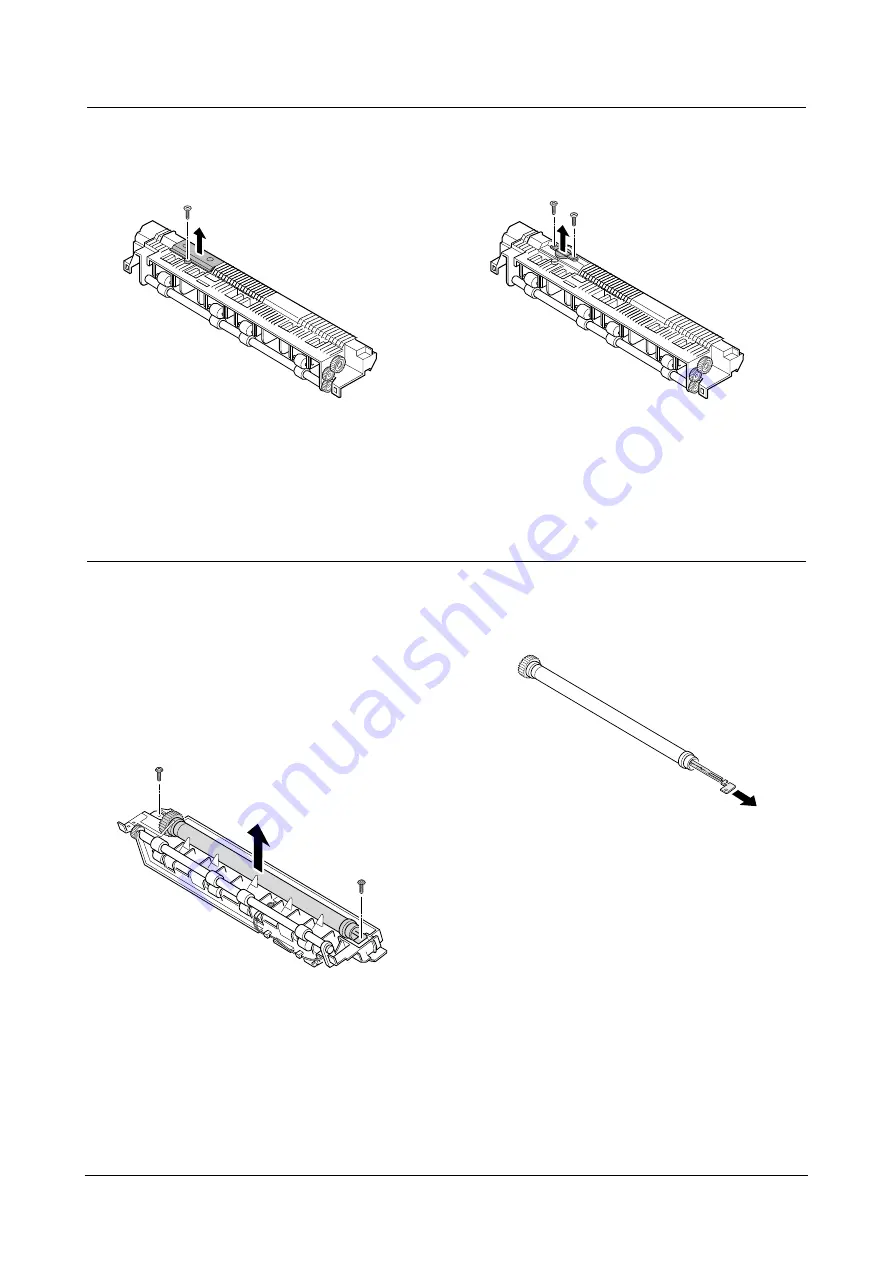

3-29 Halogen Lamp

1. Before you remove the Thermostat, you should

remove:

– All Covers (see page 3-3, 3-9)

– Fuser Ass’y (see page 3-17)

2. On the Fuser Ass’y, remove the two screws, then

remove the Heat Roller.

3. Remove the Halogen Lamp from the Heat Roller.