Disassembly and Reassembly

6-5

Samsung Electronics

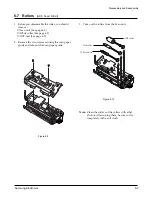

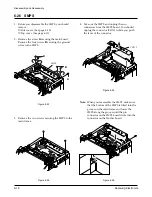

Note:

Clean the surface of the rollers with ethyl

alcohol. After wiping them, be sure to dry

completely with a soft cloth.

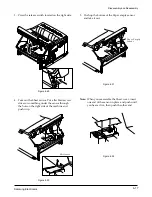

6-7 Rollers

(ADF, Feed, D.Exit)

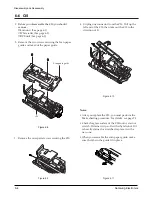

1. Before you disassemble the roller, you should

remove :

♦

Scan unit (See page 6-1)

♦

White roller (See page 6-2)

♦

OPE unit (See page 6-3)

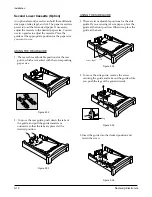

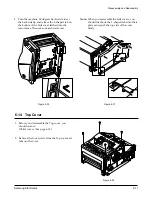

2. Remove the two screws securing the scan paper

guide and take out the Scan paper guide.

Figure 6.8

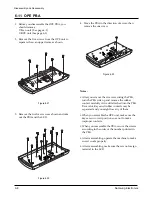

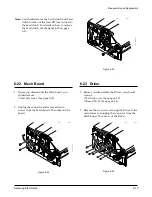

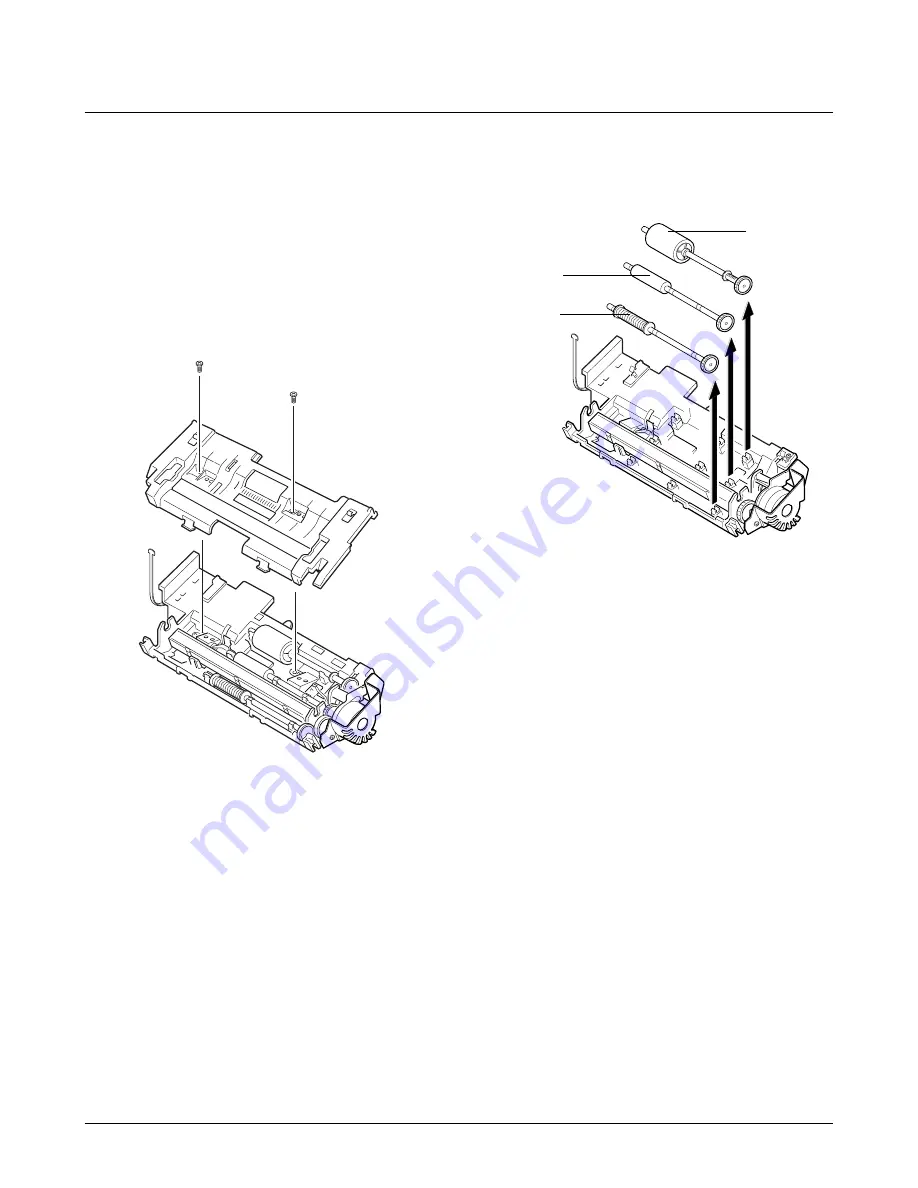

3. Take out the rollers from the Scan unit.

Figure 6.12

ADF roller

Feed roller

D. Exit roller