Summary of Contents for SH07APG

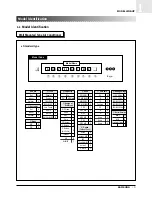

Page 2: ...Model Line Up 1 1 Model Identification 1 2 Model Line Up 1 ...

Page 3: ......

Page 8: ...Specifications 2 1 Table 2 ...

Page 9: ......

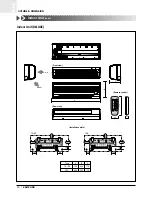

Page 12: ...Outline Dimension 3 1 Indoor Unit 3 2 Outdoor Unit 3 ...

Page 13: ......

Page 17: ...MEMO 16 SAMSUNG ...

Page 18: ...SAMSUNG 17 Performance Data 4 1 Performance Data 4 ...

Page 19: ...18 SAMSUNG ...

Page 27: ...MEMO 26 SAMSUNG ...

Page 29: ......

Page 47: ......

Page 64: ...Diagram 7 1 Refrigerating Cycle Block Diagram 7 2 Circuit Diagram 7 3 Circuit Description 7 ...

Page 65: ......

Page 76: ...Troubleshooting 8 1 Troubleshooting for Non Inverter 8 2 Set up the Model Option 8 ...

Page 77: ......

Page 92: ...MEMO SAMSUNG 91 ...

Page 93: ...MEMO 92 SAMSUNG ...

Page 94: ...ELECTRONICS Samsung Electronics Co Ltd Feb 2004 Printed in Korea Code No DB98 16444A 1 ...