2-4

Samsung Electronics

Alignment and Adjustment

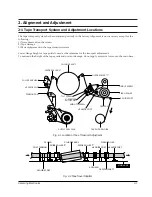

2-2-3 Check Transitional Operation from

RPS to Play

Check transition from RPS mode to play mode :

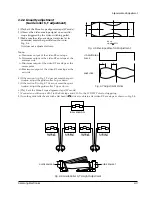

Using a pre-recorded SP tape, make sure the entry

side of envelope comes to an appropriate steady state

within 3 seconds (as shown in Fig. 2-9).

If the envelope waveform does not reach specified

peak-to peak amplitude within 3 seconds, adjust as

follows :

1) Make sure there is no gap between the supply

roller lower flange and the tape.

If there is a gap, adjust the supply guide roller

again.

2) Change operation mode from the RPS to the play

mode (again) and make sure the entry side of

envelope rises within 3 second.

ENTRANCE SIDE ENVELOPE

Fig. 2-9 Video Envelope Rising when Operation

mode Changes from RPS to Play Mode

2-2-4 Envelope Check

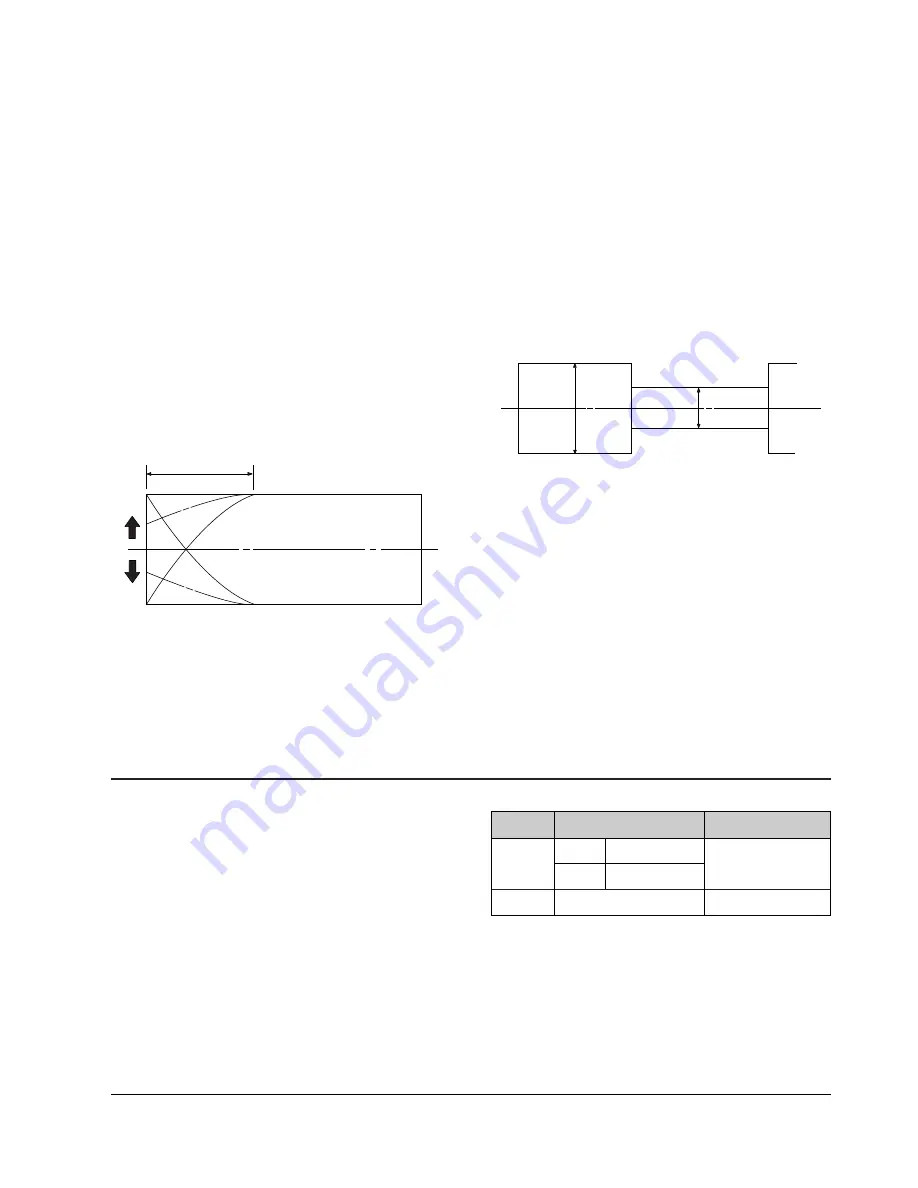

1) Make recordings on T-120 (E-120) and T-160

(E-180) tape.

Make sure the playback output envelope meets the

specification as shown in Fig. 2-10.

2) Play back a self recorded tape (recording made on

the unit using with T-120 (E-120).

The video envelope should meet the specification

as shown in Fig. 2-10.

In SP mode, (A) should equal (B).

If the head gap is wide, upper cylinder should be

checked.

A

B

Fig. 2-10 Envelope Output and Output Level

2-2-5 Tape Wrinkle Check

1) Run the T-160 (E-180) tape in the playback, FPS,

RPS and Pause modes and observe tape wrinkle at

each guide.

2) If excessive tape wrinkle is observed, perform the

following adjustments in Playback mode :

3

Tape wrinkle at the guide roller S, T section :

Linearity adjustment.

3

Tape wrinkle at tape guide flange :

ACE head assembly coarse adjustment.

2-3 Reel Torque

1) The rotation of the capstan motor causes the

Holder Clutch AssÕy to rotate through the Belt

Pulley.

2) The spring wrap PLAY/REV of holder clutch assÕy

drives the disk reel S, T through gear idle by

rotation of gear center assÕy.

3) Brake is operated by slider cam at FF/REW mode.

4) Transportation of accurate driving force is done by

gears. (Gear Center AssÕy)

Note :

If the spec. does not meet the followings speci-

fications, replace the holder clutch assÕy and then

recheck.

MODE

TORQUE g/cm

GAUGE

PB

NTSC 82.5 ± 27.5

Cassette Torquemeter

PAL 79 ± 27

RPS

145 ± 30

Cassette Torquemeter

<Table 2-1>

Summary of Contents for SV-DVD1EA

Page 8: ...Product Specifications 2 2 Samsung Electronics MEMO ...

Page 40: ...Troubleshooting 5 20 Samsung Electronics MEMO ...

Page 50: ...Exploded View and Parts List 6 10 Samsung Electronics MEMO ...

Page 62: ...7 12 Electrical Parts List Samsung Electronics MEMO ...

Page 63: ...Samsung Electronics 8 1 8 Block Diagram ...

Page 64: ...Block Diagram 8 2 Samsung Electronics MEMO ...

Page 66: ...PCB Diagrams 9 2 Samsung Electronics 9 1 S M P S ...

Page 67: ...PCB Diagrams 9 3 Samsung Electronics 9 2 VCR Main ...

Page 68: ...PCB Diagrams 9 4 Samsung Electronics 9 3 DVD Main COMPONENT SIDE SOLDER SIDE ...

Page 69: ...PCB Diagrams 9 5 Samsung Electronics 9 4 Function Timer 9 5 DVD Deck ...

Page 70: ...PCB Diagrams 9 6 Samsung Electronics MEMO ...

Page 71: ...Samsung Electronics 10 1 10 Wiring Diagram ...

Page 72: ...Wiring Diagram 10 2 Samsung Electronics MEMO ...

Page 75: ...Schematic Diagrams 11 3 Samsung Electronics 11 1 S M P S ...

Page 76: ...Schematic Diagrams 11 4 Samsung Electronics 11 2 Power Drive ...

Page 77: ...11 3 Function Timer Schematic Diagrams 11 5 Samsung Electronics ...

Page 78: ...Schematic Diagrams 11 6 Samsung Electronics 11 4 System Control Servo ...

Page 79: ...Schematic Diagrams 11 7 Samsung Electronics 11 5 A V ...

Page 80: ...Schematic Diagrams 11 8 Samsung Electronics 11 6 TM Blcok ...

Page 81: ...Schematic Diagrams 11 9 Samsung Electronics 11 7 Digital Audio ...

Page 82: ...Schematic Diagrams 11 10 Samsung Electronics 11 8 Hi Fi ...

Page 83: ...Schematic Diagrams 11 11 Samsung Electronics 11 9 OSD ...

Page 84: ...Schematic Diagrams 11 12 Samsung Electronics 11 10 Input Output ...

Page 85: ...Schematic Diagrams 11 13 Samsung Electronics 11 11 A2 NICAM ...

Page 86: ...Schematic Diagrams 11 14 Samsung Electronics 11 12 SECAM OPTION ...

Page 87: ...Schematic Diagrams 11 15 Samsung Electronics KEY OPTION 11 13 DVD Main Micom AV Decoder ...

Page 88: ...Schematic Diagrams 11 16 Samsung Electronics 11 14 Servo ...

Page 89: ...Schematic Diagrams 11 17 Samsung Electronics 11 16 DVD Deck ...

Page 90: ...Schematic Diagrams 11 18 Samsung Electronics MEMO ...

Page 115: ...2 6 Samsung Electronics Alignment and Adjustment MEMO ...