Disassembly and Reassembly

5-17

Samsung Electronics

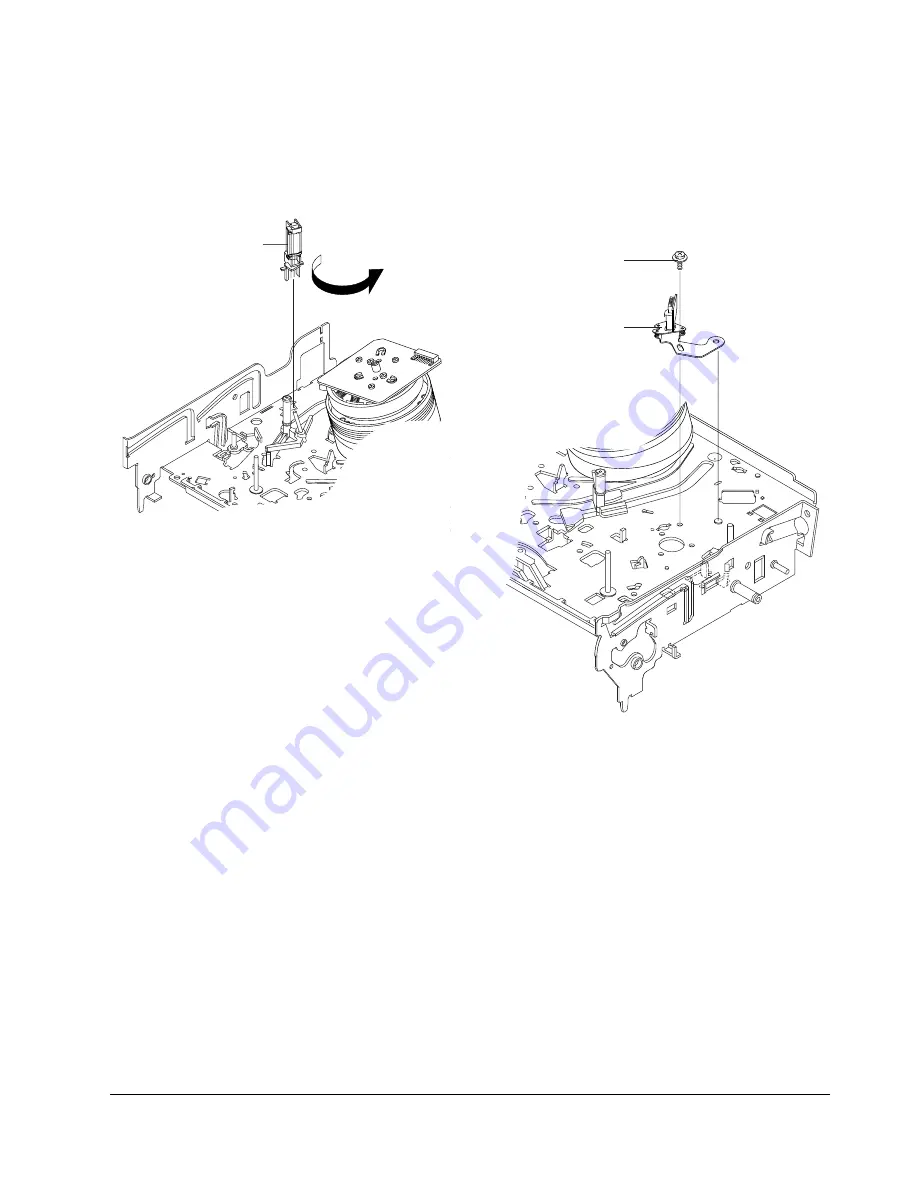

5-4-22 ACE Head Removal

1) Pull out the FPC from connector of ACE Head

Ass’y

´

.

2) Remove the screw

Œ

.

3) Lift the ACE Head Ass’y

´

.

Œ

SCREW

´

HEAD ACE ASS`Y

Fig. 5-35 ACE Head Removal

5-4-21 FE Head Removal

1) Remove the screw

Œ

.

2) Lift the FE Head

´

.

Œ

FE HEAD

Fig. 5-34 FE Head Removal

Summary of Contents for SV-DVD40

Page 82: ...Circuit Operating Descriptions 7 7 Fig 7 12 Block Diagram ...

Page 116: ...Circuit Operating Descriptions 7 41 3 Block Diagram Fig 7 38 LA70100M Block Diagram ...

Page 141: ...VCR Deck Operating Description 8 12 Samsung Electronics Fig 8 14 Mecha Timing Chart ...

Page 156: ...Samsung Electronics 11 1 11 Wiring Diagram ...

Page 158: ...Schematic Diagrams 12 2 Samsung Electronics 6 1 S M P S ...

Page 159: ...Schematic Diagrams Samsung Electronics 12 3 6 2 Power Drive ...

Page 160: ...Schematic Diagrams 12 4 Samsung Electronics DT701 6 3 Display Function ...

Page 161: ...Schematic Diagrams Samsung Electronics 12 5 6 4 System Control Servo ...

Page 162: ...Schematic Diagrams 12 6 Samsung Electronics 6 5 A V ...

Page 163: ...Schematic Diagrams Samsung Electronics 12 7 6 6 Hi Fi ...

Page 164: ...Schematic Diagrams 12 8 Samsung Electronics 6 7 A2 NICAM ...

Page 165: ...Schematic Diagrams Samsung Electronics 12 9 6 8 SECAM Option ...

Page 166: ...Schematic Diagrams 12 10 Samsung Electronics 6 9 OSD VPS PDC ...

Page 167: ...Schematic Diagrams Samsung Electronics 12 11 6 10 TM ...

Page 168: ...Schematic Diagrams 12 12 Samsung Electronics 6 11 Input Output ...

Page 169: ...Schematic Diagrams Samsung Electronics 12 13 6 12 DVD AV Decoder ...

Page 170: ...Schematic Diagrams 12 14 Samsung Electronics 6 13 DVD Servo ...

Page 171: ...Schematic Diagrams Samsung Electronics 12 15 6 14 DVD Audio Video ...