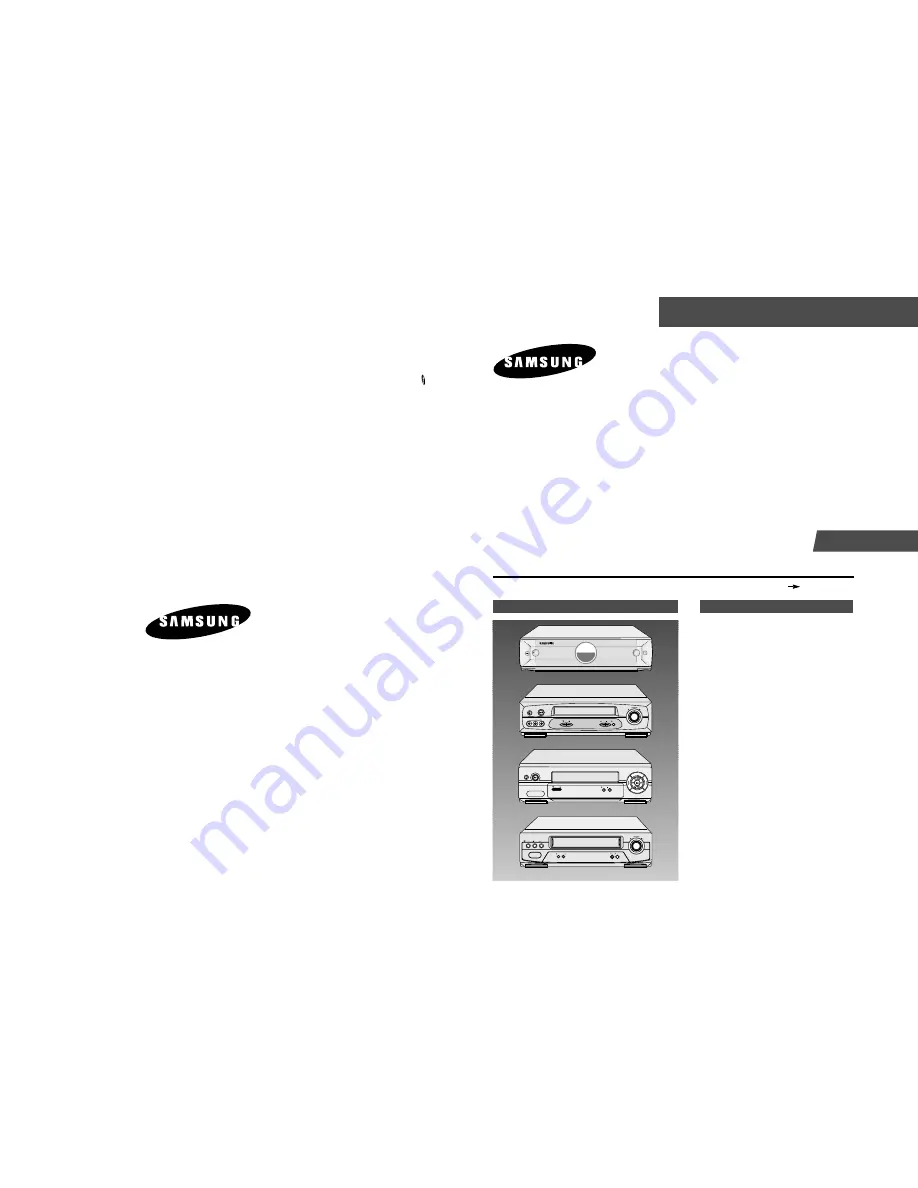

VIDEO CASSETTE RECORDER

SVR-639

SVR-633

SVR-630

SVR-537

SERVICE

1. Precautions

2. Alignment and Adjustment

3. Exploded View and Parts List

4. Electrical Parts List

5. Schematic Diagrams

Manual

VIDEO CASSETTE RECORDER

CONTENTS

For mechanical disassembly and adjustment, refer to the “Mechanical Manual” (DX-9R AC68-00001A).

SERVICE MANUAL

SVR-639/633/630/537

ELECTRONICS

© Samsung Electronics Co., Ltd.

APR. 2000

Printed in Korea

AC68-00887A

SVR-639

SVR-633

SVR-630

SVR-537

SRC PLAY

STANDBY/ON

REC STOP PLAY

PROG

EJECT

STANDBY/ON

LINE IN 2

REW

F.F

VIDEO L AUDIO R

EJECT

STANDBY/ON

REW F.F

PLAY

PROG

REC STOP

REC PLAY

STANDBY/ON EJECT STOP

SHARPNESS

REW

F.F

Summary of Contents for SVR-537

Page 17: ...Exploded View and Parts List 3 8 Samsung Electronics MEMO ...

Page 26: ...Schematic Diagrams Samsung Electronics 5 3 5 1 S M P S ...

Page 27: ...Schematic Diagrams 5 4 Samsung Electronics 5 2 Power Drive ...

Page 29: ...Schematic Diagrams 5 6 Samsung Electronics 5 4 Audio Video ...

Page 30: ...Schematic Diagrams Samsung Electronics 5 7 5 5 Hi Fi ...

Page 31: ...Schematic Diagrams 5 8 Samsung Electronics 5 6 RF VCP ...

Page 32: ...Schematic Diagrams Samsung Electronics 5 9 5 7 SECAM SVR 639 Only ...

Page 33: ...Schematic Diagrams 5 10 Samsung Electronics 5 8 Input Output 1 Scarrt Jack SVR 639 Only ...

Page 34: ...Schematic Diagrams Samsung Electronics 5 11 5 9 Input Output RCA Jack ...

Page 35: ...Schematic Diagrams 5 12 Samsung Electronics 5 10 OSD ...

Page 36: ...Schematic Diagrams Samsung Electronics 5 13 5 11 VFD Display SVR 639 ...

Page 37: ...Schematic Diagrams 5 14 Samsung Electronics 5 12 LED Module Display SVR 633 SVR 630 ...

Page 38: ...Schematic Diagrams Samsung Electronics 5 15 5 13 LED Single Display SVR 537 ...

Page 40: ...Schematic Diagrams Samsung Electronics 5 17 5 15 Remote Control Multi TV ...

Page 41: ...Schematic Diagrams 5 18 Samsung Electronics 5 16 Remote Control VCR Only ...

Page 66: ...2 6 Samsung Electronics Alignment and Adjustment MEMO ...