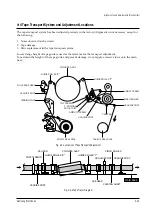

Alignments and Adjustments (Mechanical)

4-6

Samsung Electronics

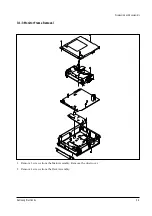

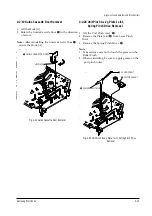

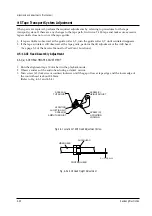

4-2-5 Slider FL Drive Removal

1. Pull the Slider FL Drive

Œ

to the front direction.

2. Remove the Slider FL Drive

Œ

in the direction of arrow. (Refer to Fig. 4-8)

Œ

SLIDER FL DRIVE

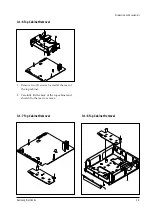

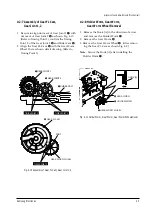

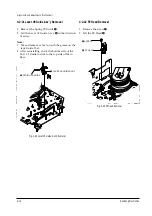

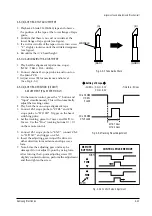

4-2-6 Bracket Gear, Gear FL Cam, Gear Joint 1, 2 Removal

1. Remove screw

Œ

.

2. Lift the Bracket Gear

´

.

3. Remove the Gear FL Cam

ˇ

.

4. Lift the Gear Joint 2

¨

, Gear Joint 1

ˆ

.

Œ

SCREW

´

BRACKET GEAR

ˇ

GEAR FL CAM

ˆ

GEAR JOINT 1

¨

GEAR JOINT 2

Fig. 4-8 Slider FL Drive Removal

Fig. 1-9 Bracket Gear, Gear FL Cam, Gear Joint 1, 2 Removal

Summary of Contents for TW14C52S/BWT

Page 89: ...11 Wiring Diagram 11 1 C15A Wiring Diagram Wiring Diagram Samsung Electronics 11 1 ...

Page 90: ...Wiring Diagram 11 2 Samsung Electronics 11 2 C15A Wiring Diagram ...

Page 94: ...Schematic Diagrams 12 4 Samsung Electronics 12 4 VCR POWER BLOCK ...

Page 97: ...Schematic Diagrams 12 7 Samsung Electronics 12 7 TV 3 4 RED POWER LINE BLUE SIGNAL LINE ...