E-

18

E-

18

Insulation

Before completing the installation (insulation of the hose and piping),

you must check that there are no gas leaks.

To check for gas leaks on the...

Then, using a leak detector,

check the...

Outdoor unit

Valves on sections A and B.

A

B

A

B

A

B

A

B

Performing leak tests

Connecting the drain hose to the outdoor unit

Once you have checked that there are no leaks in the system, you can insu-

late the piping and hose.

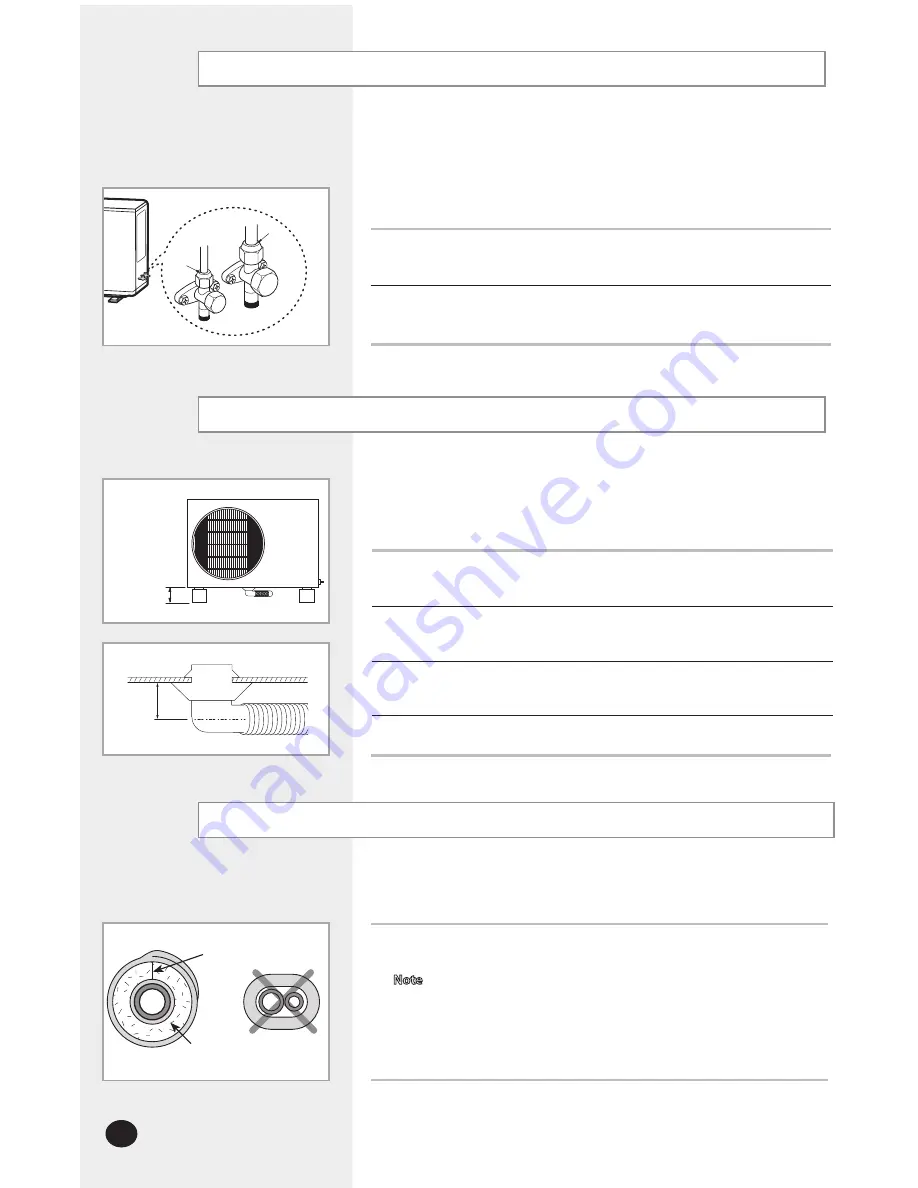

To avoid condensation problems, place an insulator around each

refrigerant pipe.

1

When insulate the pipe, be sure to overlap the insulation.

You have to use more than 120°C insulation(T13.0 or thicker

Acrylonitrile Butadien Rubber) for the gas refrigerant pipe.

Note

No gap

NBR(T13.0 or thicker)

When using the air conditioner in the heating mode, ice may accumu-

late. During de-icing, the condensed water must be drained off safely.

Consequently, you must install a drain hose on the outdoor unit, following the

instructions below.

Make space more than 50mm between the bottom of the outdoor unit

and the ground for installation of the drain hose, as shown in figure.

1

Insert the drain plug into the hole on the underside of the outdoor unit.

2

Connect the drain hose to the drain plug.

3

Ensure that the drained water runs off correctly and safely.

4

50mm min.

50mm min.

30mm