INDOOR UNIT

AS18WJWB

AS18WJWD

AS18WJWE

AST18WJWB

AST18WJWE

AS24W6WB

AS24W6WE

AST24W6WB

AST24W6WE

SC18ZWJ

SC24ZW6

OUTDOOR UNIT

US18WJWB

US18WJWD

US18WJWE

UST18WJWB

UST18WJWE

US24W6WB

US24W6WE

UST24W6WB

UST24W6WE

SC18ZWJX

SC24ZW6X

SERVICE

Manual

CONTENTS

AIR CONDITIONER

1. Product Specifications

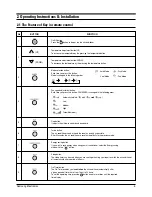

2. Operating Instructions & Installation

3. Disassembly and Reassembly

4. Refrigerating Cycle Diagram

5. Set Up the Model Option

6. Troubleshooting

7. Exploded Views and Parts List

8. Block Diagram

9. Wiring Diagram

ROOM AIR CONDITIONER

Summary of Contents for US18WJWB

Page 42: ...MEMO 41 Samsung Electronics ...

Page 46: ...MEMO 45 Samsung Electronics ...

Page 56: ...MEMO 55 Samsung Electronics ...

Page 57: ...MEMO Samsung Electronics 56 ...